Get the model ready to fly – Top Flite TOPA0706 User Manual

Page 28

28

GET THE MODEL READY TO FLY

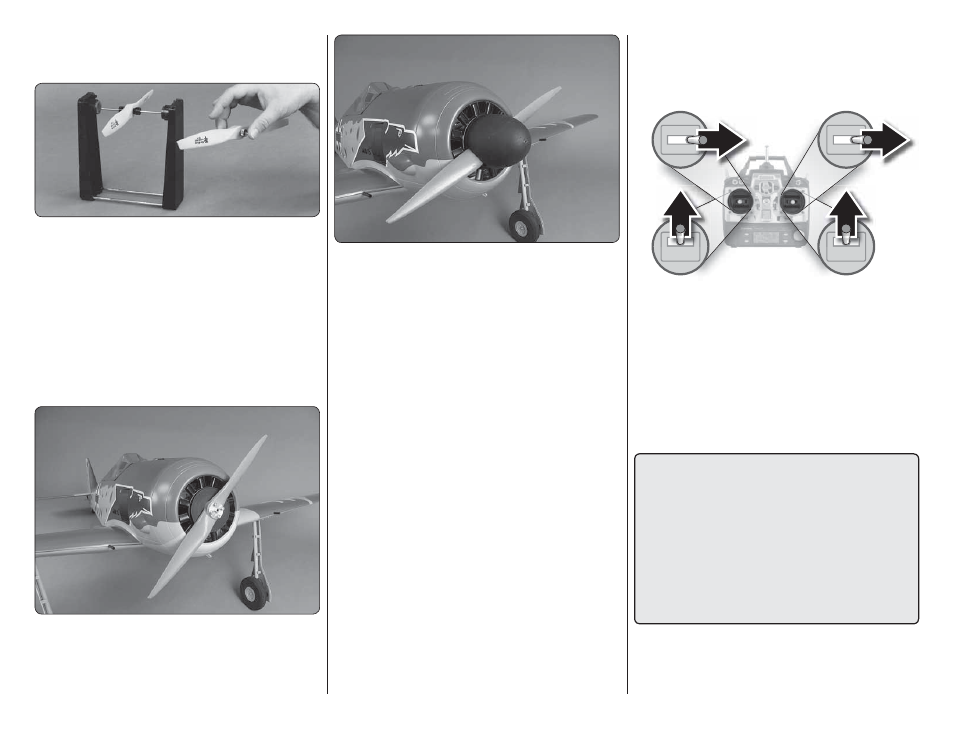

INSTALL THE PROPELLER

❏

1. Carefully balance the propeller and any spare

propellers. An unbalanced propeller can be the single

most signifi cant cause of vibration that can damage

the model. Not only will engine mounting bolts loosen,

possibly with disastrous effect, but vibration may also

damage the receiver and receiver batteries. Vibration

can also cause the fuel to foam, which will, in turn, cause

the engine to run hot and quit.

We use a Top Flite Precision Magnetic Prop Balancer

(TOPQ5700) in the workshop and keep a Great Planes

Fingertip Prop Balancer (GPMQ5000) in our fl ight box.

❏

2. The included aluminum spinner was designed to

be used with the DA-50, DLE-55 and the O.S. GT55

gas engines. Drill the bolt holes through the propeller,

slide the spinner backplate, propeller and prop washer

on the engine prop shaft and install the prop bolts.

❏

3. Install the spinner cone on the engine using an M5 x

85mm socket head cap screw. Use a drop of threadlocker

on the threads. For a more realistic appearance Top

Flite also offers a 3-bladed spinner (TOPA1882) for the

3-blade Zinger prop.

BALANCE THE MODEL LATERALLY

❏

1. With the wing level, have an assistant help you lift

the model by the engine propeller shaft and the bottom

of the fuse under the TE of the fi n. Do this several times.

❏

2. If one wing always drops when you lift the model,

it means that side is heavy. Balance the airplane by

adding weight to the other wing tip. An airplane that

has been laterally balanced will track better in loops

and other maneuvers.

CHECK THE CONTROL DIRECTIONS

❏

1. Switch on the transmitter and receiver and center

the trims. If necessary, remove the servo arms from

the servos and reposition them so they are centered.

Reinstall the screws that hold on the servo arms.

❏

2. With the transmitter and receiver still on, check

all the control surfaces to see if they are centered. If

necessary, adjust the clevises on the pushrods to center

the control surfaces.

FULL

THROTTLE

RUDDER

MOVES

RIGHT

ELEVATOR

MOVES DOWN

RIGHT AILERON

MOVES UP

LEFT AILERON

MOVES DOWN

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

❏

3. Make certain that the control surfaces and the

carburetor respond in the correct direction as shown in

the diagram. If any of the controls respond in the wrong

direction, use the servo reversing in the transmitter to

reverse the servos connected to those controls. Be

certain the control surfaces have remained centered.

Adjust if necessary.

SET THE CONTROL THROWS

To ensure a successful fi rst fl ight, set up your Giant Fw

190A-3 ARF according to the control throws specifi ed

in this manual. The throws have been determined

through actual fl ight testing and accurate record-

keeping, allowing the model to perform in the manner

in which it was intended. If, after you have become

accustomed to the way the Giant Fw 190A-3 ARF

fl ies, you would like to change the throws to suit your

taste, that is fi ne. However, too much control throw

could make the model too responsive and diffi cult

to control, so remember, “more is not always better.”