Top Flite TOPA0706 User Manual

Page 23

23

❏

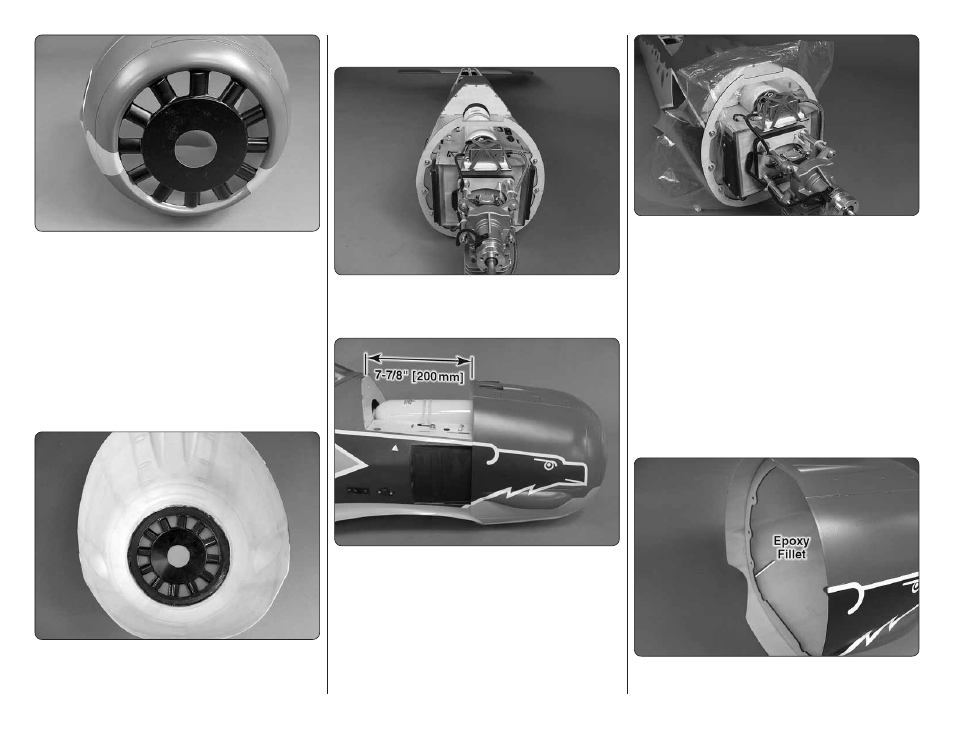

3. Center the plastic fan in the cowl opening. Apply

a couple drops of thin CA to the joint between the fan

and the cowl to hold it in place.

❏

4. Lightly sand the inside of the cowl around the edge

of the plastic fan. Clean the area with a paper towel

dampened with denatured alcohol.

❏

5. Apply a bead of epoxy to the back of the outer

ring of the fan and the front and edge of the plywood

fan ring. Position the plywood ring on top of the plastic

fan. Place weight on the ring to hold it in position until

the epoxy cures.

❏

6. Use epoxy to make a fi llet between the cowl and

the edge of the plywood fan ring. For a stronger fi llet

milled fi berglass can be mixed with the epoxy.

See page 35 for instructions on how to make a

long 7/64" Hex-ball Wrench.

❏

7. Attach the plywood cowl ring to the front of the

fuselage with six 6-32 x 5/8" socket head cap screws,

#6 lock washers and #6 fl at washers.

❏

8. Test fi t the cowl over the engine. The bottom of the

cowl will need to be trimmed to fi t over the engine head.

For right now just get the cowl fan centered around the

engine drive washer and the cowl in the correct position

7-7/8" [200mm] from the back of the air tank tray.

❏

9. Remove the cowl and the cowl ring. Cut a hole in

the center of the plastic bag the cowl came in and slide

the plastic bag over the front of the fuselage so that it

covers the fi rewall. Reinstall the cowl ring. The bag is

to prevent glue from getting on the fuselage when the

cowl is glued to the cowl ring.

❏

10. Sand the inside of the cowl where the cowl ring

contacts the cowl. Then, clean it with a paper towel

dampened with denatured alcohol.

❏

11. Mix up 1/2 oz. [4 drams] of 30-minute epoxy. Apply

the epoxy to the inside of the cowl where it contacts the

cowl ring. Slide the cowl over the cowl ring, centering

it over the drive washer on the engine and aligning it

correctly on the fuselage. Use masking tape to hold it

in position until the epoxy cures.

❏

12. Remove the cowl using the included long hex

wrench. Use epoxy to make a fi llet between the cowl and