Slant/Fin VSPH-180 User Manual

Page 6

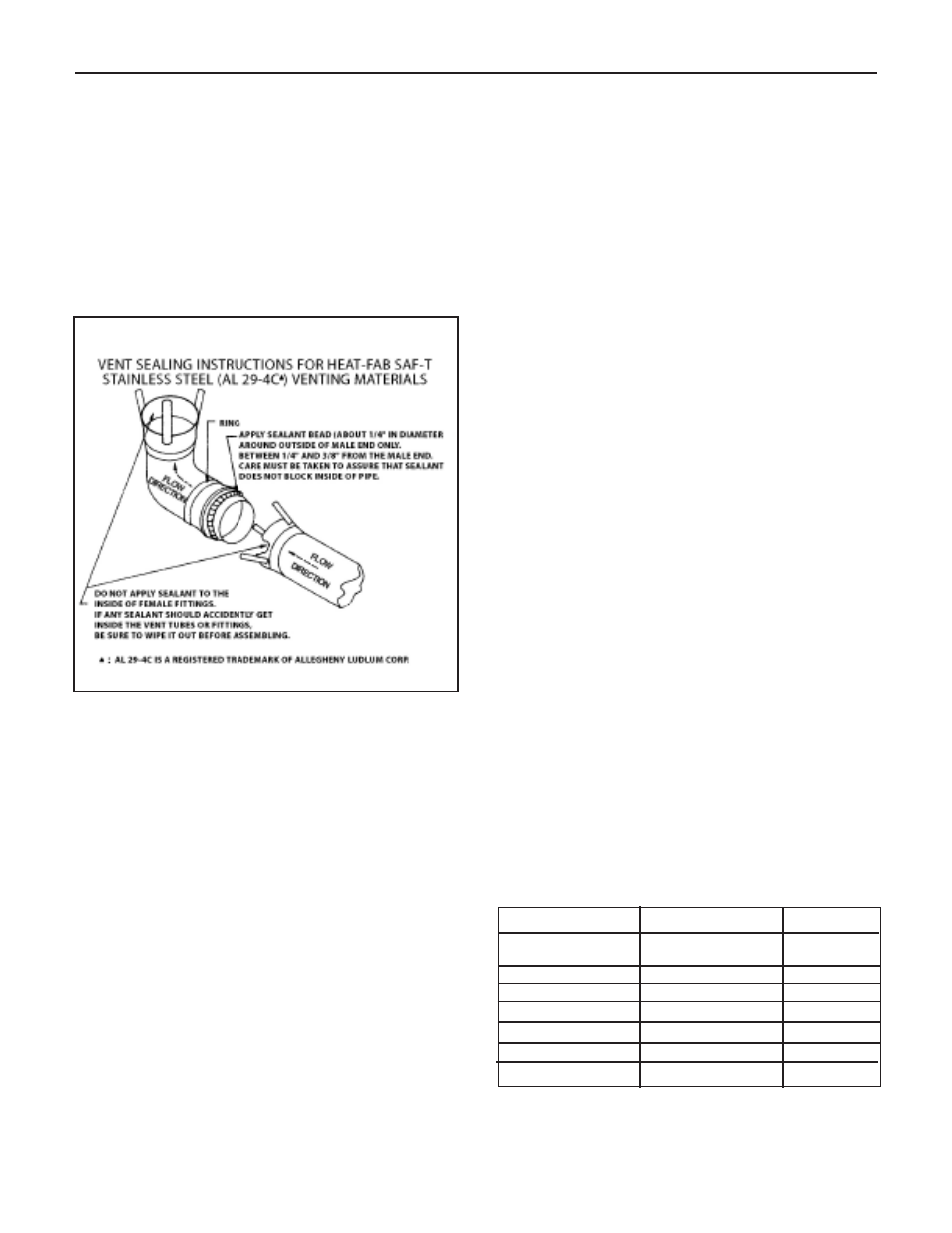

When joining the various components of the above listed

vent systems, the manufacturers’ instructions should be

closely followed to insure proper sealing. Use sealant speci-

fied by vent system manufacturer for sealing of pipe and fit-

tings. See Figure 4 for proper application of vent pipe sealing

for Saf-T vent system by Heat-Fab, Inc. All vent connections

must be liquid and pressure tight. Flue vent system CANNOT

be cut to length. Consult manufacturer’s instructions. For Heat-

Fab system, use slip joint connector to adjust pipe lengths

dimensions.

DO NOT use plastic or galvanized flue pipe.

AIR INTAKE PIPE MATERIAL

3” PVC Schedule 40 or galvanized steel materials are rec-

ommended.

All joints must be sealed using appropriate sealants.

FLUE AND AIR INTAKE RESTRICTIONS

1. Maximum allowed equivalent flue and air intake length for

different flue systems at different altitudes are given in the

tables on page 7.

2. Equivalent of flue or air intake length is sum of the

straight pipe lengths and equivalent length of elbows as

shown in the table on this page.

3. The vent termination is in addition to the allowed equiva-

lent lengths.

4. Minimum flue length is 2 feet.

5. Flue length restriction is for both direct and non-direct

vent installations.

EXAMPLE: Boiler model VSPH-180 is to be installed at sea

level. The combustion air is provided by air intake piping

directly to the boiler (direct-vent installation). Flue piping

includes 2 elbows and using Heat-Fab system. Air intake is

PVC and includes 3 elbows.

Maximum straight flue length would be 30-2x3=24 feet.

Maximum straight air intake pipe would be 40-3x5=25 feet.

If the air for combustion were taken from the boiler room

(non-direct vent installation), still the maximum straight flue

length would be 24 feet.

6.

All Victory VSPH boilers are equipped with a built-in

condensation drain and trap. The trap loop must be

filled with water. DO NOT operate the boiler without

filling the trap with water to prevent flue gas discharge

into space. The drain should extend to a floor drain or

to a container which may require emptying periodically.

7.

The horizontal vent pipe must be sloped upward from

the boiler at a pitch of at least

1

⁄

4

" per 1 foot of run, so

that the condensate from the vent system runs to the

drain trap.

8.

The horizontal vent pipes must be supported with pipe

straps at intervals no greater than indicated by vent

pipe manufacturer’s instructions. The vertical portion

vent pipe also must be supported per manufacturer’s

instructions. Support air intake piping in the same

manner as the vent pipes.

9.

Minimum clearances of vent pipes from combustible

constructions must be maintained (see Page 4). Main-

tain minimum 1" clearance between vent pipes and

PVC air intake pipes.

10.

Common venting with other appliances or another

VSPH boiler is not allowed.

11.

DO NOT install a vent damper or similar devices in

vent system or on the boiler.

12.

Do not insulate venting system.

V

ICTORY VSPH Models

6

Figure: 4

Vent Sealing Instructions

(Consult vent manufacturer’s instructions.)

Heat-Fab, Inc.

Saf-T Standard

3

elbow

Heat-Fab, Inc.

Saf-T, tight radius elbow

6

ProTech System, Inc.

FasNseal

6

Flex-L International, Inc.

StaR-34

6

Z-Flex, Inc.

Z-Vent

6

N/A

PVC, Schedule 40

5

N/A

Galvanized steel

6

Manufacturer

Type/System

Equivalent

Length (Feet)

Equivalent Length of Various 90-Degree Elbows