Slant/Fin VSPH-180 User Manual

Page 15

V

ICTORY VSPH Models

15

VENTING AND AIR INTAKE SYSTEM REGULAR

INSPECTION

A. Inspect the system regularly for condensation, corrosion

and/or physical damage. A qualified professional should ser-

vice the boiler annually and include such an inspection at that

time. The homeowner should look over the system monthly for

damage, water stains, any signs of rust, other corrosions or

separation of the vent and air intake piping (if direct-vent).

B. Should an inspection turn up signs of condensation, corrosion

or damage, the boiler should be shut down immediately and

the condition should be corrected by a qualified professional.

C. All Victory VSPH boilers are equipped with a built-in conden-

sation drain and trap. The trap loop must be filled with water.

DO NOT operate the boiler without filling the trap with water to

prevent flue gas discharge into space. Periodic inspection

should be made of this assembly for deterioration of the tub-

ing and to insure that the trap is not plugged. If it is plugged or

appears to have excessive sediment in it, it should be

removed from the drain assembly, straightened out to clear

the obstruction, reformed, filled with water and reinstalled as

before.

GAS PIPING

A. Local installation codes apply. The pipe joint compound

used on threads must be resistant to the action of liquefied

petroleum gases.

B. The gas supply line to the boiler should run directly from the

meter for natural gas or from the fuel tank for L.P. propane

gas. See page 2 for location of union and manual main

shut-off valve that may be specified locally.

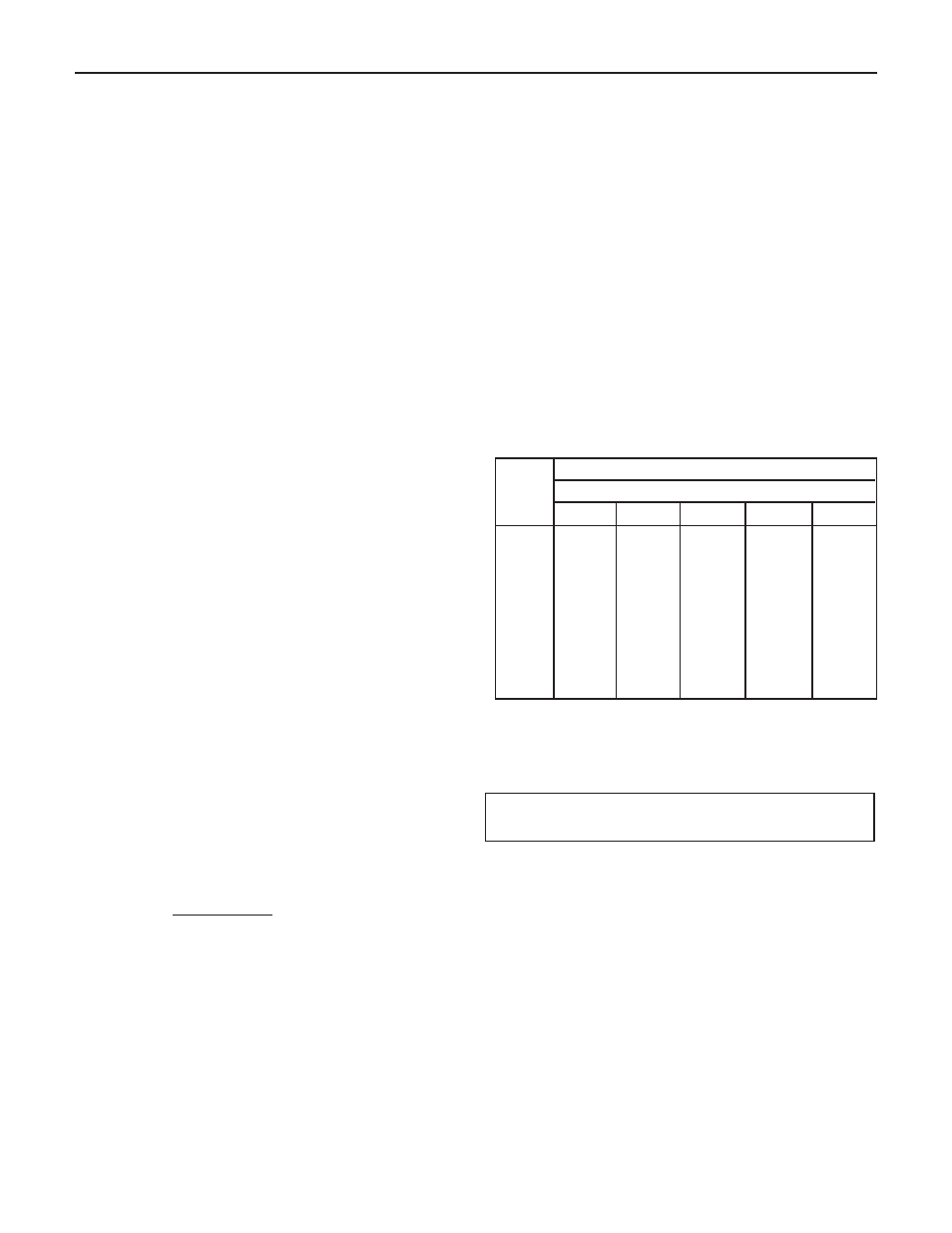

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the meter

to the installation site.

2. Consult gas supplier for heating value of gas (Btu/cu. ft.).

3. Divide boiler rated input by heating value to find gas flow

in piping (cu. ft. per hour).

4. Use table below to select proper pipe size.

EXAMPLE: Boiler model VSPH-150 is to be installed. Distance

from gas meter to the boilers is 30ft. Heating value of natural

gas is 1020 Btu/cu. Ft. Select proper pipe size.

Gas flow = 150,000 Btu/hour

= 147 cu. ft. per hour

1020 Btu/cu. ft.

At 30 ft. length of pipe, match required capacity from table on

this page (choose higher capacity, in this case is 152 cu. ft. per

hour). Required pipe size is

3

⁄

4

".

Improper gas pipe sizing will result in pilot flame outages, insuf-

ficient heat and other installation difficulties. For more informa-

tion and also if other appliances are to be attached to the pip-

ing system, see Appendix C of National Fuel Gas Code ANSI

Z223.1-latest edition.

C. The boiler and its gas connection must be leak tested

before placing the boiler in operation. Use liquid soap solu-

tion for all gas leak testing. DO NOT use open flame. This

boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure test-

ing of that system at test pressures in excess of

1

⁄

2

PSIG.

This boiler must be isolated from the gas supply piping sys-

tem by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than

1

⁄

2

PSIG.

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap must be provid-

ed, as illustrated on page 2.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for

the type of gas used. Gas supply pressure should never be

less than minimum or more than maximum pressure when

the boiler or any other appliance is turned on or off.

ELECTRICAL WIRING

DANGER: Before wiring always turn off electric power supply

otherwise, shock or death can result.

1. Power Supply

A separately fused circuit is recommended. Use standard

15 Amp. fuse or breaker and 14 gage conductors in BX

cable or conduit.

Provide disconnect means and overload protection as

required. See boiler wiring diagram (Figure 13a) boiler con-

trol (Figure13b) and ladder diagram (Figure 13c).

Boiler must be electrically grounded in accordance with the

requirements of the authority having jurisdiction, or, in the

absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70-latest edition.

Length

of pipe

in Feet

1/2

3

/

4

1

1

1

/

4

1

1

/

2

Gas Flow In piping -- cu. ft. per hr.

Iron Pipe Size (IPS) — inches

10

132

278

520

1050

1600

20

92

190

350

730

1100

30

73

152

285

590

890

40

63

130

245

500

760

50

56

115

215

440

670

60

50

105

195

400

610

70

46

96

180

370

560

80

43

90

170

350

530

90

40

84

160

320

490

100

38

79

150

305

460

At pressure drop of 0.3 in. water, specific gravity = 0.6.