Slant/Fin VSPH-180 User Manual

Page 24

V

ICTORY VSPH Models

24

CARE AND MAINTENANCE

This section must be brought to the attention of the owner by

the installer so that the owner can make the necessary

arrangements with a qualified service agency for the periodic

care and maintenance of the boiler. The installer must also

inform the owner that the lack of proper care and maintenance

of this boiler and any fuel burning equipment may result in a

hazardous condition. Installer should discuss contents of the

User’s Information Manual (Publication VSPH-UIM) with the

owner.

A trained and qualified service technician should perform the

inspection listed in these instructions before each heating sea-

son and at regular intervals.

I. General Maintenance

A. Safety check, see page 23.

B. Vent and air intake system inspection

1. Check for obstruction, condensation, corrosion and

physical damage.

2. Check outside termination. Screen and louvers should

be free of any debris and must be cleaned as required.

3. Perform “Venting and Air intake System Regular

Inspection”, see page 15.

C. Piping

Check the following:

1. Water piping and accessories for leaks. Slightest leaks

should be corrected.

2. System to be full of water and pressure to remain sta-

ble at correct setting on gauge.

3. Air-control system. Noise and air binding in radiation

should not occur.

4. Low water cutoff for operation (see instructions fur-

nished with unit).

D. Boiler Room Air Supply

Check air vents for continuous positive supply of air as

required. Air needs are greatest in cold weather if boiler

installation is non-direct vent method. Air vents must open

and free of obstruction.

Warning: The flow of combustion and ventilating air to the

boiler should not be obstructed.

II. Inspection During Heating Season

A. Check water pressure regularly and add water slowly to

system when needed. If much water is added, venting

may be necessary. Regular loss of water from boiler sys-

tem may indicate either a system leak, or a faulty air con-

trol system, or a faulty automatic fill valve.

B. Check venting system. See “Venting and Air Intake Sys-

tem Regular Inspection” on page 15.

C. Check condensation drain trap to be full of water. Check

for deterioration of the tubing. Check that the trap is not

plugged.

D. With main burner firing all LED’s mst be steady “on”. See

“Normal operation-status of indicator lights” on page 22.

E. To prolong the life of the inducer motor, lubricate with

Anderol 465 or SAE 20 motor oil annually Turn off power

and place 4-6 drops of above mentioned lubricant in each

of two oil holes. Lubricate circulator per manufacturer’s

instruction. DO NOT over oil any motor.

WARNING:

CLEANING

A. Flue passage cleaning See Figure 22

1.

Turn off power to the boiler

2.

Remove front jacket panel

3.

Remove air box front panel

4.

Remove jacket top

5.

Remove inducer assembly

6.

Remove flue collector

7.

Remove combustion air screen

8.

Use wire brush to clean flue passages. It is sug-

gested that paper be placed on burners to collect

any foreign material in cleaning flue passage.

9.

Replace flue collector and re-seal with high tem-

perature sealer or with furnace cement.

10. Remove and dispose of paper and accumulated

material.

11. Replace all removed items.

12. Check boiler operation.

B. Cleaning of burners

1.

Turn off power to the boiler.

2.

Remove jacket front, air box front panel, air intake

screen and combustion air screen located inside the

air box.

3.

Disconnect ignitor/sensor cable from the boiler con-

trol.

4.

Remove pilot gas line from brass fitting located inside

the air box.

5.

Lift burners and remove from orifices.

6.

Clean burners. To clean burners, run a clean flue

brush up the tube until all foreign matter is removed.

7.

Replace all removed items.

8.

Check boiler operation.

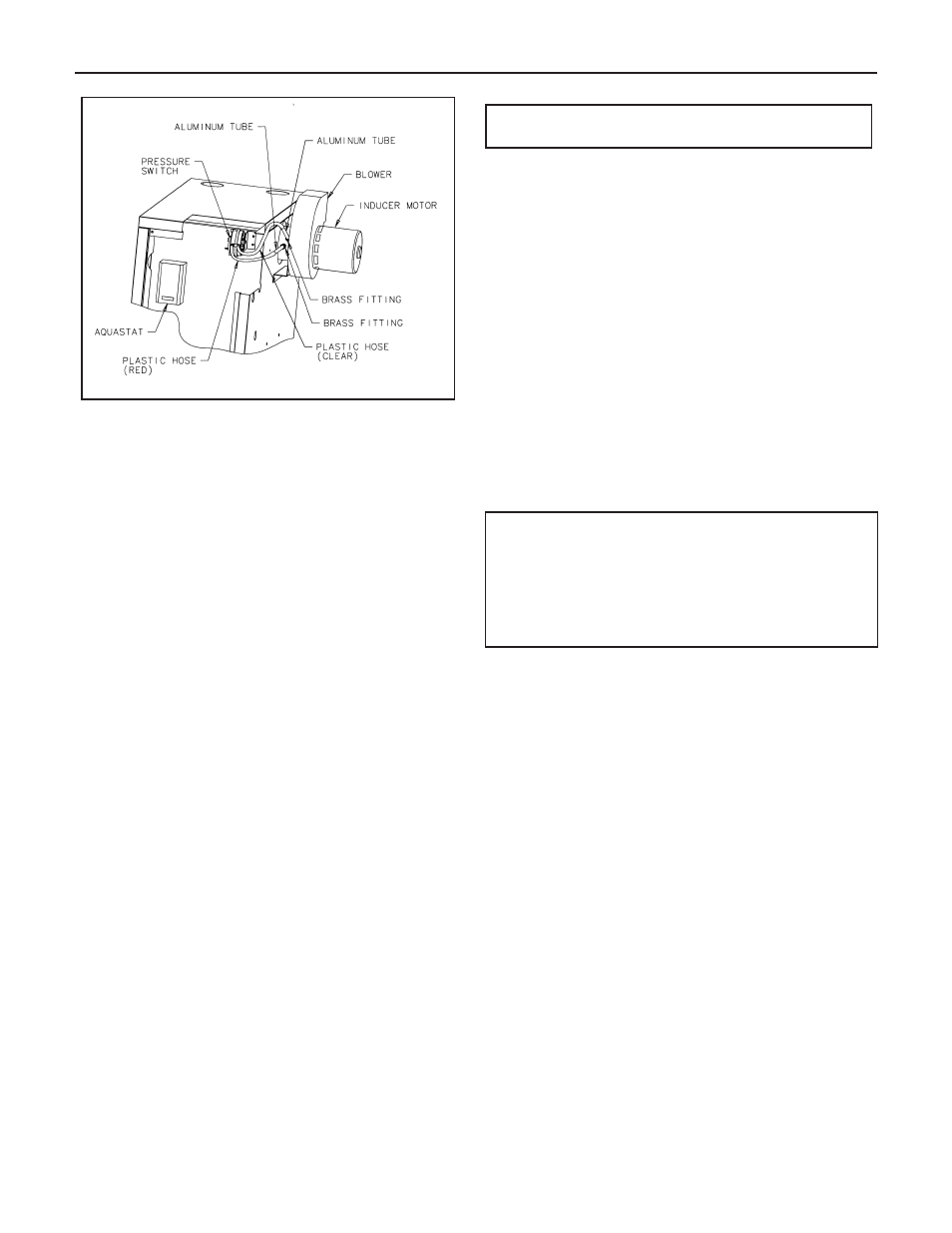

Figure 21. Location and identification of pressure

switch and hoses.

The ceramic combustion chamber in the burner box contains

crystalline silica.

Wear proper dust mask and gloves when servicing combus-

tion chamber or burners.

Crystalline Silica has been identified as a carcinogenic or

possibly carcinogenic to humans.