Calibrating the co, Display, Calibrate the co – Shellab SCO31 User Manual

Page 28: E 28, Operation (continued), Alibrating the, Isplay

28 |

P a g e

OPERATION (CONTINUED)

C

ALIBRATING THE

CO

2

D

ISPLAY

Note: The CO

2

display and sensor come calibrated from the factory to a 5% concentration at 179

Feet (54 meters) above sea level.

The calibration procedure verifies the accuracy of the CO

2

reading and

corrects for any measurement errors. Calibrate as often as required by your

laboratory or production protocol, or regulatory requirements. Sheldon

Manufacturing recommends calibrating the CO

2

display whenever the SCO

Incubator is installed in a new environment.

Always use a CO

2

reference sensor regularly calibrated to a concentration

accuracy of 0.1%. For best results use a digital gas analyzer with a sample

collection tube. The accuracy of the calibration process is limited by the

accuracy of your reference device.

The incubator should be calibrated at the CO

2

concentration level it will be set to

during your incubation application or process. Wait until the unit has stabilized at its

CO

2

set point before starting the calibration procedure. Stabilized means there have been no

changes in concentration on the unit’s CO

2

display for 1 hour while the unit is sitting undisturbed.

Failure to wait until the unit is stabilized prevents an accurate calibration from being carried out.

Procedure continued on next page

Calibrating the CO

2

Display

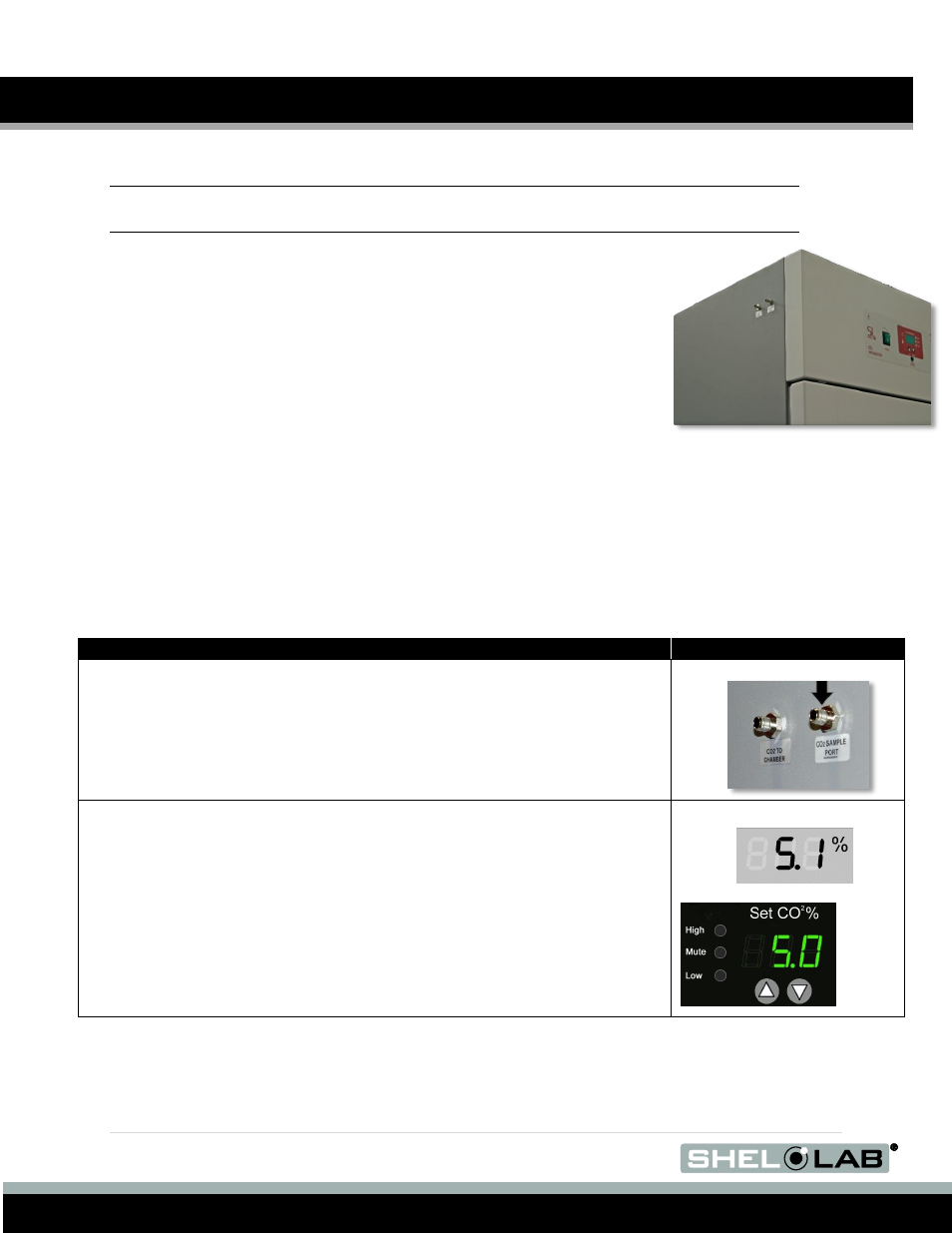

1. Connect a digital CO

2

analyzer sample tube to the sample port on

the top left side of the Incubator.

2. Measure the current CO

2

percentage (%) inside the chamber with

the CO

2

analyzer.

a. Compare that reading with the percentage (%) shown on

the incubator’s CO

2

display panel.

b. If the readings are the same or fall within your laboratory

protocol acceptable range the incubator is now

calibrated for CO

2

. The Calibrate CO

2

Display

procedure is complete.

Reference Device

CO

2

Sample Port Location