Warning – Reznor Q6SD (3ph) Unit Installation Manual User Manual

Page 8

8

Air Filter Requirements

WARNING:

Never operate the unit without a fi lter in place.

Dust and lint could accumulate on internal parts,

resulting in loss of effi ciency, equipment damage

and possible fi re. Replace disposable fi lters with

the same type and size.

• Air fi lter(s) are not supplied and must be installed in

the return air system by the installer.Only three phase

units are equipped with an internal fi lter rack assembly.

• All return air must pass through the fi lters before

entering the unit. Recommended fi lter sizes are listed

in Table 1. NOTE:

It is important that all fi lters be

kept clean and replaced frequently to ensure proper

operation of unit. Dirty or clogged fi lters will reduce

the effi ciency of the unit and result in unit shutdowns.

• Air fi lter pressure drop must not exceed 0.08 inches

WC.

When replacing the air fi lters, a suitable air fi lter

must be installed upstream of the evaporator coil of

the return air system.

• Downflow Installations require an internal filter

accessory kit to be installed.

• Horizontal Installations require the air fi lter system be

installed in the return air ductwork.

Unit Size

Internal Filter Size

Q6SD-X36

(2) 16” x 25” x 1”

or

(2) 16” x 25” x 2”

Q6SD-X48 / X60

(2) 18” x 25” x 1”

or

(2) 18” x 25” x 2”

Table 1. Internal Filter Sizes

HEAT PUMP INSTALLATION

Packaging Removal

Remove the shipping carton and User’s Manual from the

equipment. Take care not to damage the tubing connections

when removing the carton. For rooftop installations, remove

and discard the two supports attached beneath the unit.

Rigging and Hoisting

WARNING:

To avoid the risk of property damage, personal

injury, or death, it is the rigger’s responsibility

to ensure that whatever means are used to hoist

the unit are safe and adequate:

•

The lifting equipment must be adequate for the

load. Refer to Table 4 (page 15) for unit weights.

•

The unit must be lifted from the holes in the

base rails using cables or chains.

•

Spreader bars are required to protect the unit

and ensure even loading.

•

Keep the unit in an upright position at all times.

The rigging must be located outside the units

center of gravity. Refer to Figure 7 (page 15)

for locating the center of gravity.

•

All panels must be securely in place during

rigging and hoisting.

Minimum Clearance Requirements

Q6SD units are certifi ed as combination heating and

cooling equipment for outdoor installation only. Figure 2

(page 7) displays the minimum clearances to obstructions

for both downfl ow and horizontal discharge.

Units may be installed on wood fl ooring or on Class A, B,

or C roof covering material when used with bottom supply

and return air ducts as long as the following requirements

are met:

• If using horizontal supply and return air ducts, the

horizontal roof curb kit and return air kit must be

installed prior to unit installation. Horizontal roof curb

is required.

• If using bottom discharge with return air ducts a roof

curb must be installed prior to unit installation. See

Rigging and Hoisting section for setting of the unit.

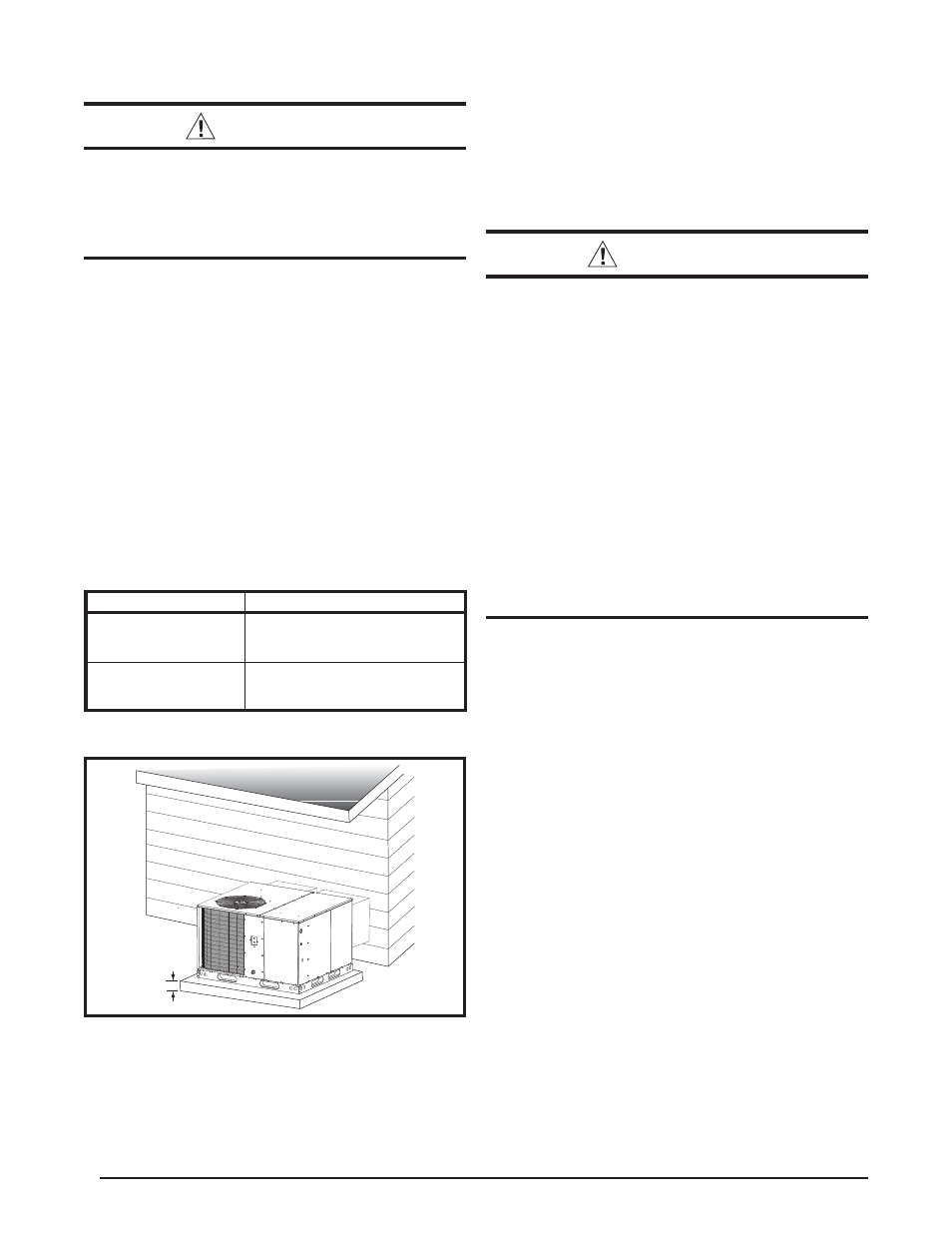

Ground Level

Ground level installations must be located according to

local building codes or ordinances and these requirements:

• Clearances must be in accordance with those shown

in Figure 2. Also consider clearances for access to the

internal fi lter.

• A suitable mounting pad (Figure 3) must be provided

and separate from the building foundation. The pad

must be level to ensure proper condensate disposal

and strong enough to support the unit’s weight. The

2”

Figure 3. Ground Level Installation