Warning, Caution – Reznor Q6SD (3ph) Unit Installation Manual User Manual

Page 11

11

Example

:

AB = 451V

BC = 460V

AC = 453V

2. Determine the average voltage in the power supply.

3. Determine the maximum deviation:

4. Determine percent of

voltage imbalance by

using the results from

steps 2 & 3 in the

following equation.

max voltage deviation

from average voltage

= 100 x

average voltage

% Voltage Imbalance

6

454

100 x

= 1.32%

Example:

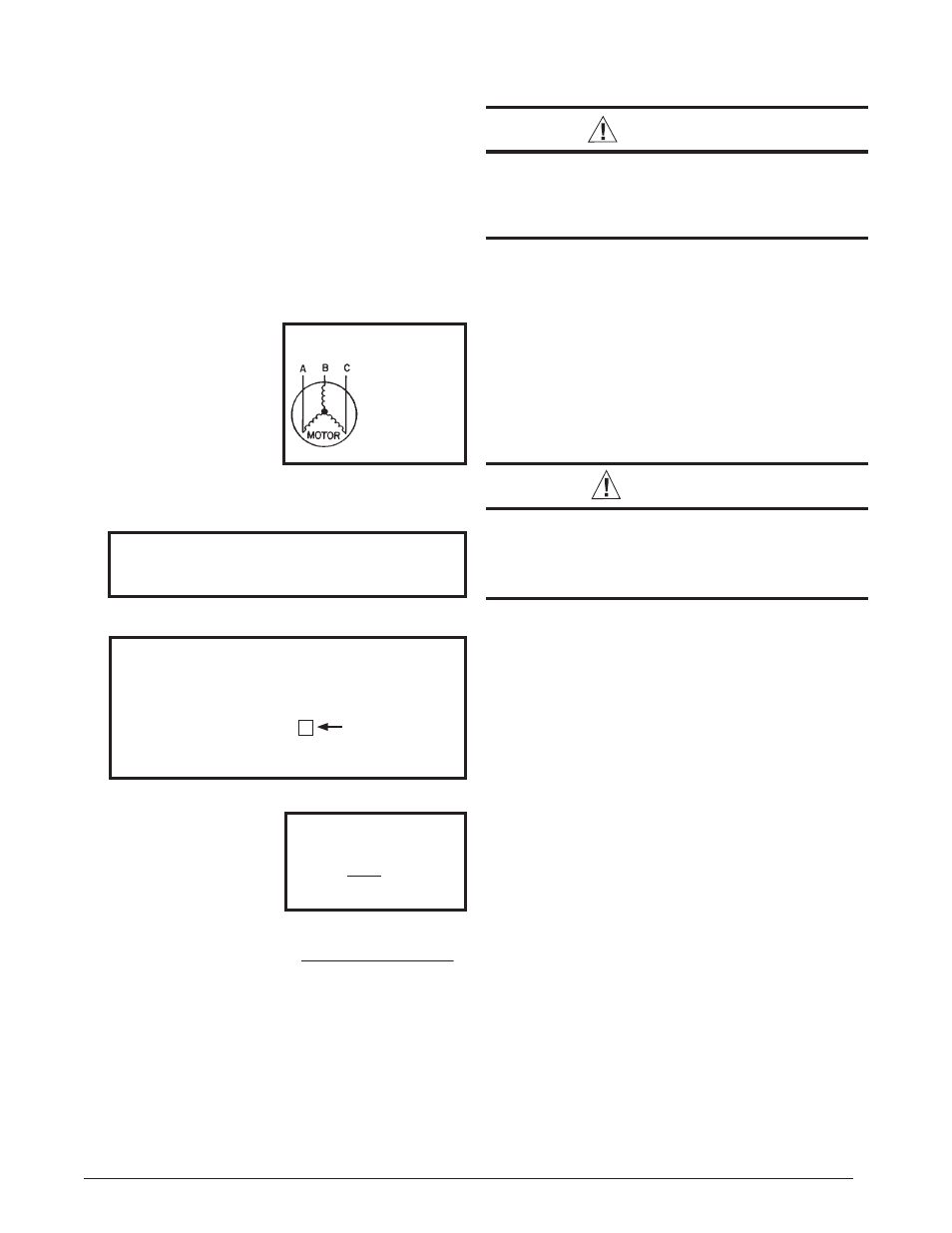

1. M e a s u r e t h e l i n e

voltages of your 3-phase

power supply where it

enters the building and

at a location that will

only be dedicated to the

unit installation. (at the

units circuit protection

or disconnect).

Unbalanced 3-Phase Supply Voltage

Voltage unbalance occurs when the voltages of all phases

of a 3-phase power supply are no longer equal. This

unbalance reduces motor effi ciency and performance.

Some underlying causes of voltage unbalance may include:

Lack of symmetry in transmission lines, large single-phase

loads, and unbalanced or overloaded transformers. A

motor should never be operated when a phase imbalance

in supply is greater than 2%.

Perform the following steps to determine the percentage

of voltage imbalance:

In this example, the measured line voltages were

451, 460, and 453. The average would be 454 volts

(451 + 460 + 453 = 1,364 / 3 = 454).

The amount of phase imbalance (1.32%) is satisfactory

since the amount is lower than the maximum allowable

2%. Please contact your local electric utility company if

your voltage imbalance is more than 2%.

Example:

From the values given in step 1, the BC voltage

(460V) is the greatest difference in value from

the average:

460 - 454 = 6

454 - 451 = 3

454 - 453 = 1

Highest Value

Grounding

WARNING:

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. Do not

use gas piping as an electrical ground

!

This unit must be electrically grounded in accordance

with local codes or, in the absence of local codes, with

the National Electrical Code (ANSI/NFPA 70) or the CSA

C22.1 Electrical Code. Use the grounding lug provided in

the control box for grounding the unit.

Blower Speed

The blower speed is preset at the factory for operation at

the same speed for heating and cooling. These factory

settings are listed in Table 5 (page 21). For optimum

system performance and comfort, it may be necessary

to change the factory set speed.

CAUTION:

To avoid personal injury or property damage,

make sure the motor leads do not come into

contact with any uninsulated metal components

of the unit.

1. Shut off all electrical power to the unit and remove

the blower panel. Locate the orange and red wires

terminated to the blower motor. NOTE: The orange

wire controls cooling operation while the red wire

controls heating operation.

2. Verify the required speed from the airfl ow data found

in Table 5. Place appropriate wire on the correct motor

speed tap for the required airfl ow point.

Defrost Cycle Timer

The defrost cycle timer controls the time interval of the hot

gas defrost after the defrost sensor closes. It is located

in the lower left corner of the defrost control board on the

low voltage side of the control box. Three interval settings

are available: 30 minutes, 60 minutes, and 90 minutes.

Time setting selection is dependent on the climate where

the unit is being installed.

• Example 1: Dry climate of Southern Arizona - A 90

minute setting is recommended.

• Example 2: Moist climate of Seattle, Washington - A

30 minute setting is recommended.

To set the cycle timer, place the timing pin on the defrost

control board to the desired time interval post. NOTE: All

units are shipped from the factory with the default time

setting of 30 minutes.