Unit maintenance, Troubleshooting, Warning – Reznor B6BM Unit Installation Manual User Manual

Page 16

16

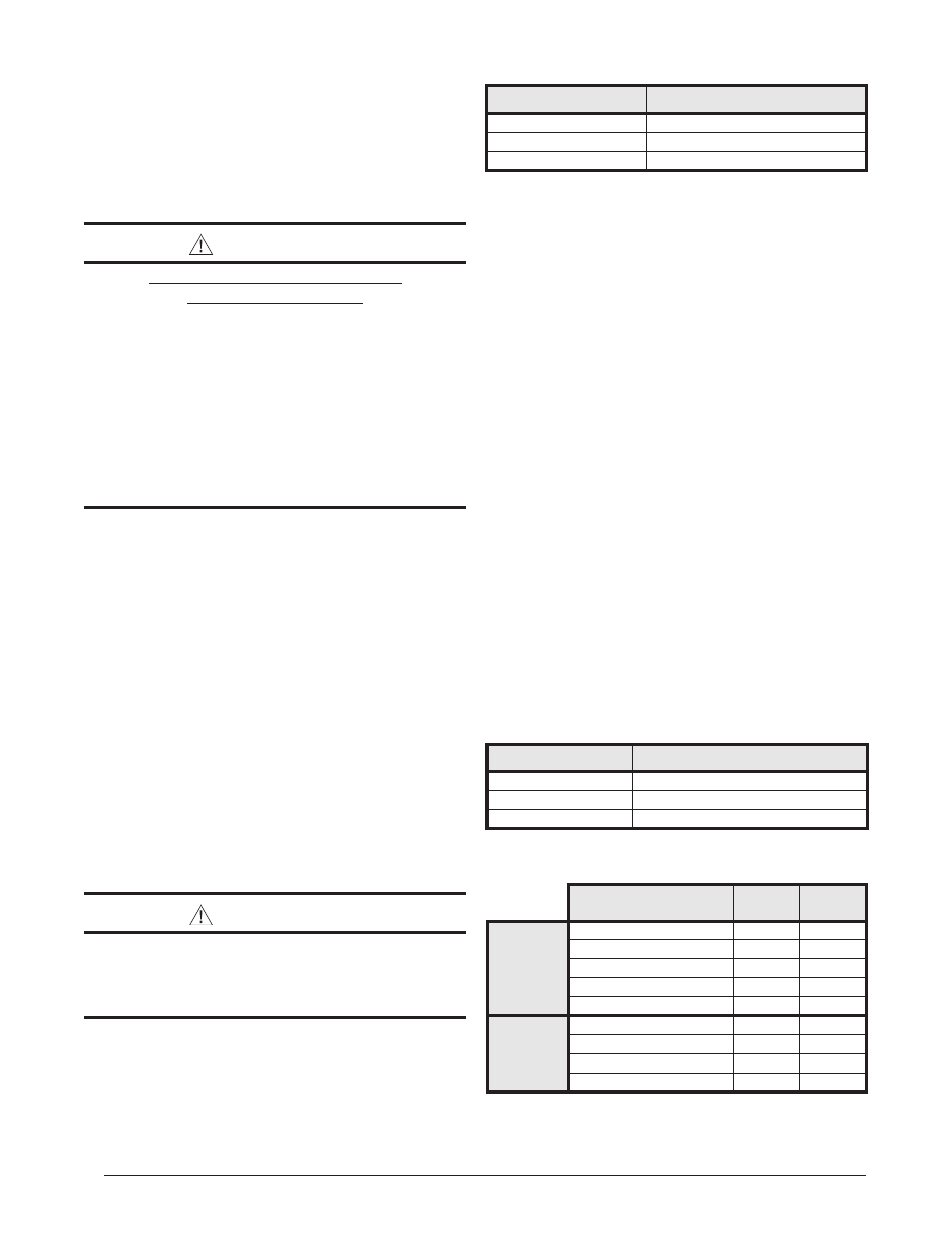

Table 2. Filter Sizes

CABINET SIZE

FILTER SIZE

A

12 x 20 x 1

B

18 x 20 x 1

C

20 x 20 x 1

RED LED (AN2)

DIAGNOSTIC

OFF

Control Fault (No Power)

Flash

Blower Fault

ON

Normal Operation

Table 3. Air handler Control Board Fault Conditions

UNIT MAINTENANCE

Proper maintenance is most important to achieve the best

performance from a air handler. Some of the components

and their locations are shown in

. If

any component of the air handler must be replaced, use

only factory authorized replacement parts specified in the

Replacement Parts List provided online.

WARNING:

ELECTRICAL SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical power

to the indoor blower.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

• These maintenance instructions are primarily intended

to assist qualified technicians experienced in the proper

maintenance and operation of this appliance.

• Always reinstall the doors on the air handler after

servicing or cleaning/changing the filters.

Do not operate

the air handler without all doors and covers in place.

• Verify that the thermostat is properly installed and is

not being affected by drafts or heat from lamps or other

appliances.

• To achieve the best performance and minimize

equipment failure, it is recommended that a yearly

maintenance checkup be performed. At a minimum,

this check should include the following items:

Air Filter(s) - B6 Series Air Handlers are not supplied

with a single air filter when shipped from the factory. It

is recommended that the filter be cleaned or replaced

every 4 to 6 months at a minimum. Newly built or recently

renovated homes may require more frequent changing

until the construction dust has minimized. Filter sizes

are available at most local retailers.

WARNING:

Never operate the air handler without a filter in

place. Dust and lint in the return air can build

up on internal components, resulting in loss of

efficiency, equipment damage, and possible fire.

Filters designed to remove smaller particles such as

pollen, may require additional maintenance.

Blower Compartment - Dirt and lint can create excessive

loads on the motor resulting in higher than normal

operating temperatures and shortened service life. It is

recommended that the blower compartment be cleaned of

dirt or lint that may have accumulated in the compartment

or on the blower and motor as part of the annual inspection.

Blower Fan Wheel - Inspect the blower wheel blades

for accumulations of dirt and clean if necessary. Inspect

mounting nut for tightness when done.

Blower Motor & Assembly - Inspect the blower assembly

and motor mounting brackets for tightness and corrosion.

Correct deficiencies if necessary. The blower motor

contains sealed bearings and under normal operating

conditions, no maintenance is necessary for the life of

the equipment.

TROUBLESHOOTING

If the air handler fails to operate, check the following:

• Is the electric turned on?

• Is the thermostat operating properly?

• Are the blower compartment door(s) in place?

• Is the air handler disconnect closed?

• Has the circuit breaker tripped or the control board fuse

burned open?

• Are any manual reset switches open?

• Is the filter dirty or plugged?

• Is the LED on both control boards constantly ON? If not,

refer to

to determine fault condition.

Table 4. Motor Control Board Fault Conditions

DIAGNOSTIC

GREEN

LED

RED

LED

FIXED

SPEED

FURNACES

C

ontrol

F

ault

(n

o

P

ower

)

Off

Off

n

ormal

o

Peration

On

On

m

otor

F

ault

On

Flash

t

win

F

ault

(

no

motor

Fault

)

Flash

On

C

ommuniCations

F

ault

Flash

Flash

VARIABLE

SPEED

FURNACES

C

ontrol

F

ault

(n

o

P

ower

)

Off

Off

n

ormal

o

Peration

On

On

m

otor

F

ault

On

Flash

C

ommuniCations

F

ault

Flash

Flash