4 heat section condensate drain, Cooling coil installation instructions (cont'd) – Reznor ACUB Option - Installation - ACU - Cased Cooling Coil User Manual

Page 6

Form I-CAUA-CC, Page 6

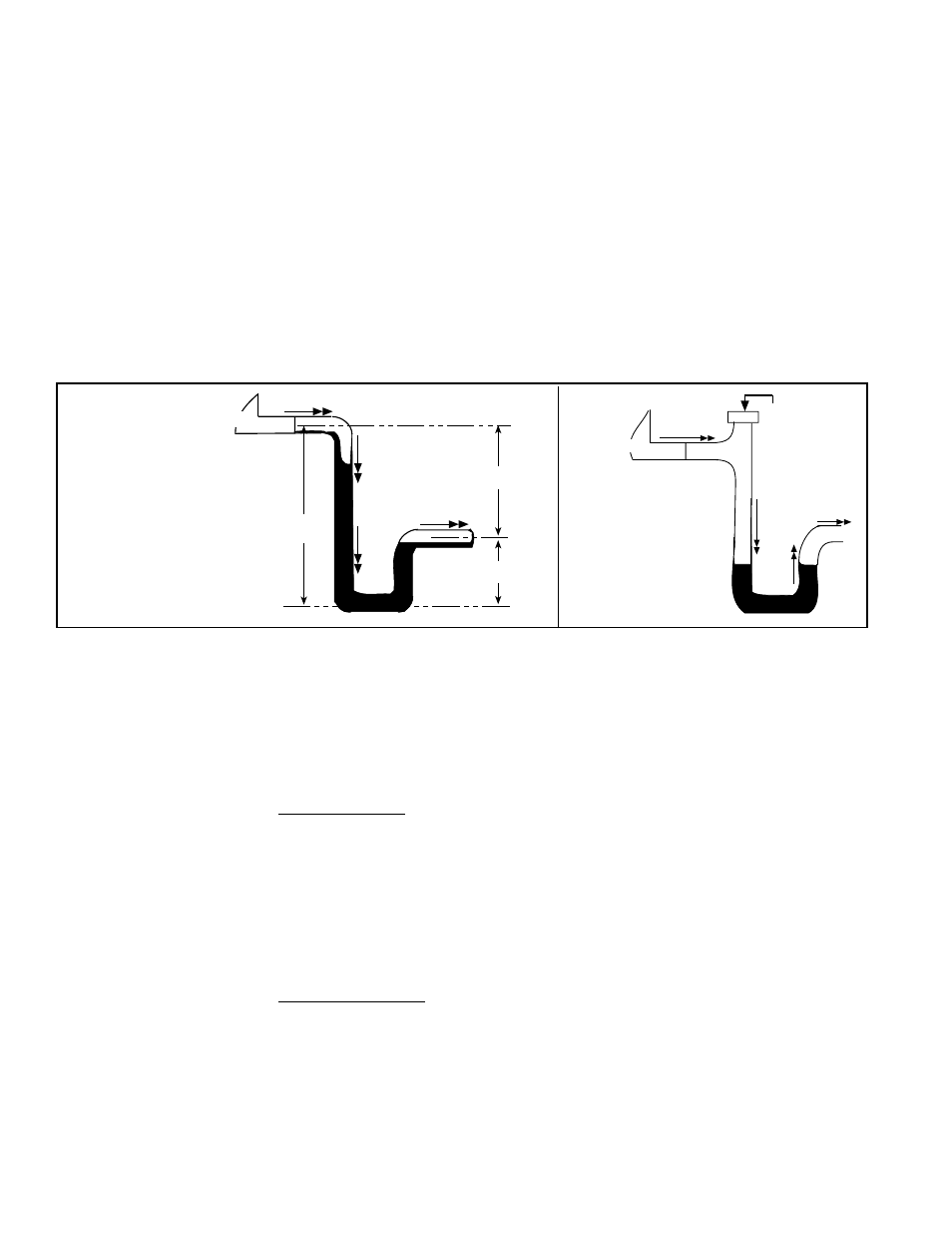

To prevent air

from entering

always close

the cleanout.

Water Flow

Unit

FIGURE 4B -

Drain

Trap with

Cleanout

B

A

A/2

C

L

C

L

C

L

Unit

Water Flow

Water Flow

A = 3" (76mm)

minimum

B = A + A/2

FIGURE 4A -

Condensate

Drain Trap

Dimensions

Improper trap design accounts for some condensate drainage system failures,

but incorrect use and maintenance of condensate drain traps can also cause

problems. The combination of airborne particles and moisture in the air handler

can result in algae formation in the drain pan and traps. The traps must be

cleaned regularly to avoid blockage that can slow or stop water flow, resulting

in backup into the system.

If drains have a cleanout opening (

FIGURE 4B), be sure to close the opening

after cleaning.

Condensate Drain

Use

4. Cooling Coil

Installation

Instructions

(cont'd)

4.4 Heat Section

Condensate

Drain

When a cooling coil is installed on a Model CAUA heater, a heat section con-

densate drain line must be installed.

The parts to install the drain line are packaged and shipped with all Model

CAUA heaters.

Seasonal Usage - At the beginning of the cooling season, inspect and clean

the entire cooling coil cabinet including the condensate drain pan. Thoroughly

clean dirt, algae, grease, and other contaminates. Inspect condensate drain

pans, traps, and piping; fill traps with water to ensure proper operation. During

a wintertime shutdown of the cooling system it may be desirable to disconnect

and remove all water from the traps and drains to prevent freeze damage. If

local building codes permit, traps may be filled with an antifreeze solution. Or,

piping may be designed with freeze plugs or other freeze protection methods

(such as a heat tape).

Year Round Usage - Climates or applications with cooling requirements year

round require more frequent inspections of the cooling coil cabinet and conden-

sate drains. Depending on climate, freeze protection of traps may be required

during non-cooling hours.

Condensate Drain Trap

The design of the drain trap is important. If dimension "B" in

FIGURE 4A is

not tall enough, the water seal will not hold, and air will be drawn through the

drain pipe into the system. If the outlet leg of the trap is too tall, water will back

up into the drain pan. As condensate forms during normal operation, the water

level in the trap rises until there is a constant outflow.

FIGURE 4A illustrates

the appropriate dimensions.

4.3 Drain Line

The cased coil has a 3/4" FPT drain connection; see location in

FIGURE 1.

page 2. Install a trap (see below) and pitch the drain line downward at least 1/2"

(13mm) for every 10 feet (3M) of horizontal run. Drain lines must not interfere

with access panels. An obstruction in the drain or a poorly designed drain can

cause an over flow. Overflow could result in unit or building damage.

Connect the heat section condensate tubing (see Paragraph 4.4) into the cool-

ing coil drain line and continue into a sanitary drain system.

Condensate Drain

Trap