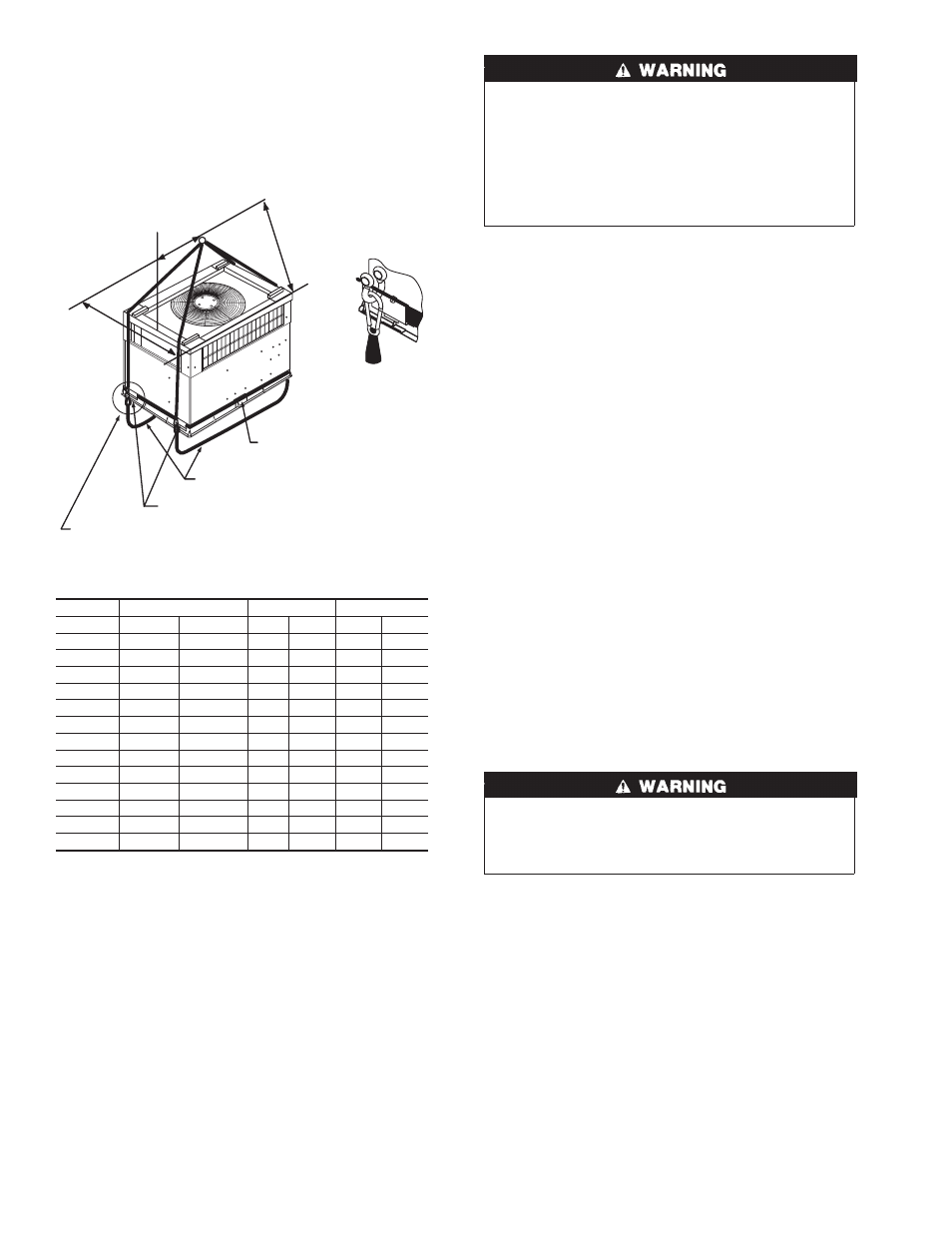

Fig. 8—suggested rigging – Carrier 50JS User Manual

Page 6

5. Tighten the tension buckle until it is taut. Lifting brackets

must be secure in the handholds.

6. Attach field-supplied clevis or hook of sufficient strength to

hole in the lifting bracket (See Fig. 8).

7. Attach the 2 safety straps directly to the clevis or hook at the

4 rigging brackets. DO NOT attach the safety straps to the

lifting brackets (See Fig. 8).

8. Position lifting point directly over the unit’s center of gravity.

9. Lift unit. When unit is directly over the roof curb, remove the

2 safety straps. Lower the equipment onto the roof curb.

Step 5—Select and Install Ductwork

The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

non-residence type air conditioning and ventilating systems, NFPA

90A or residence-type, NFPA 90B and/or local codes and ordi-

nances.

Select and size ductwork, supply-air registers, and return air grilles

according to ASHRAE (American Society of Heating, Refrigera-

tion, and Air Conditioning Engineers) recommendations.

The unit has duct flanges on the supply- and return-air openings on

the side of the unit.

When designing and installing ductwork, consider the following:

For vertical supply and return units, tools or parts could drop

into ductwork and cause serious injury or death. Install a 90

degree turn in the return ductwork between the unit and the

conditioned space. If a 90 degree elbow cannot be installed,

then a grille of sufficient strength and density should be

installed to prevent objects from falling into the conditioned

space. Units with electric heaters require 90 degree elbow in

supply duct.

1. All units should have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recommended

sizes for filters are shown in Tables 1A and 1B.

2. Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT:

Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The minimum

air quantity for proper electric heater operation is listed in

Tables 2A and 2B. Heater limit switches may trip at air

quantities below those recommended.

4. Seal, insulate and weatherproof all external ductwork. Seal,

insulate and cover with a vapor barrier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and Air

Conditioning Contractors National Association (SMACNA)

and Air Conditioning Contractors Association (ACCA) mini-

mum installation standards for residential heating and air

conditioning systems.

5. Secure all ducts to building structure. Flash,weatherproof, and

vibration-isolate duct openings in wall or roof according to

good construction practices.

CONVERTING

HORIZONTAL

DISCHARGE

UNITS

TO

DOWNFLOW (VERTICAL) DISCHARGE UNITS

Before performing service or maintenance operations on

system, turn off main power to unit. Turn off accessory heater

power switch if applicable. Electrical shock could cause

serious injury or death.

1. Open all electrical disconnects before starting any service

work.

2. Remove side duct covers to access bottom return and supply

knock outs.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the base pan.

4. Reinstall the side duct covers to block off the horizontal air

openings.

NOTE:

These panels are held in place with tabs similar to an

electrical knockout.

NOTE:

Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

Step 6—Provide for Condensate Disposal

NOTE:

Ensure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

UNIT

MAXIMUM WEIGHT

A

B

Size

lb.

kg.

in.

mm.

in.

mm.

50JS018

305

138.4

19.5

495.3

16.75

425.5

50JS024

311

141.1

18.5

469.9

16.75

425.5

50JS030

309

140.2

19.5

495.3

17.50

444.5

50JS036

313

142.0

19.5

495.3

17.75

450.9

50JS042

345

156.4

19.5

495.3

17.75

450.9

50JS048

375

170.1

20.5

520.7

20.62

523.8

50JS060

440

199.6

19.5

495.3

19.75

501.7

50JX024

321

145.6

19.0

482.6

18.25

463.6

50JX030

342

155.2

20.0

508

19.25

489

50JX036

350

158.8

20.0

508

19.0

482.6

50JX042

372

168.8

21.0

533.4

20.5

520.7

50JX048

377

171.0

20.0

508

21.25

539.8

50JX060

450

204.2

21.0

533.4

20.0

508.0

Fig. 8—Suggested Rigging

C99075

PLACE RIGGING BRACKET ASSEMBLY IN 4

HAND HOLES AND INSTALL TIE DOWN STRAP

AROUND PERIMETER OF UNIT AND THROUGH

SPACE IN BRACKET ASSEMBLY

INSTALL SAFETY STRAPS TO

RIGGING CLEVIS AT 4 RIGGING BRACKETS

TIGHTEN STRAPPING SECURELY

WITH TENSION BUCKLE

SEE DETAIL A

DETAIL A

SCALE 0.250

914-137"

(36"-54")

“A”

“B”

6