Cooling and heating troubleshooting chart (cont’d) – Carrier 50JS User Manual

Page 25

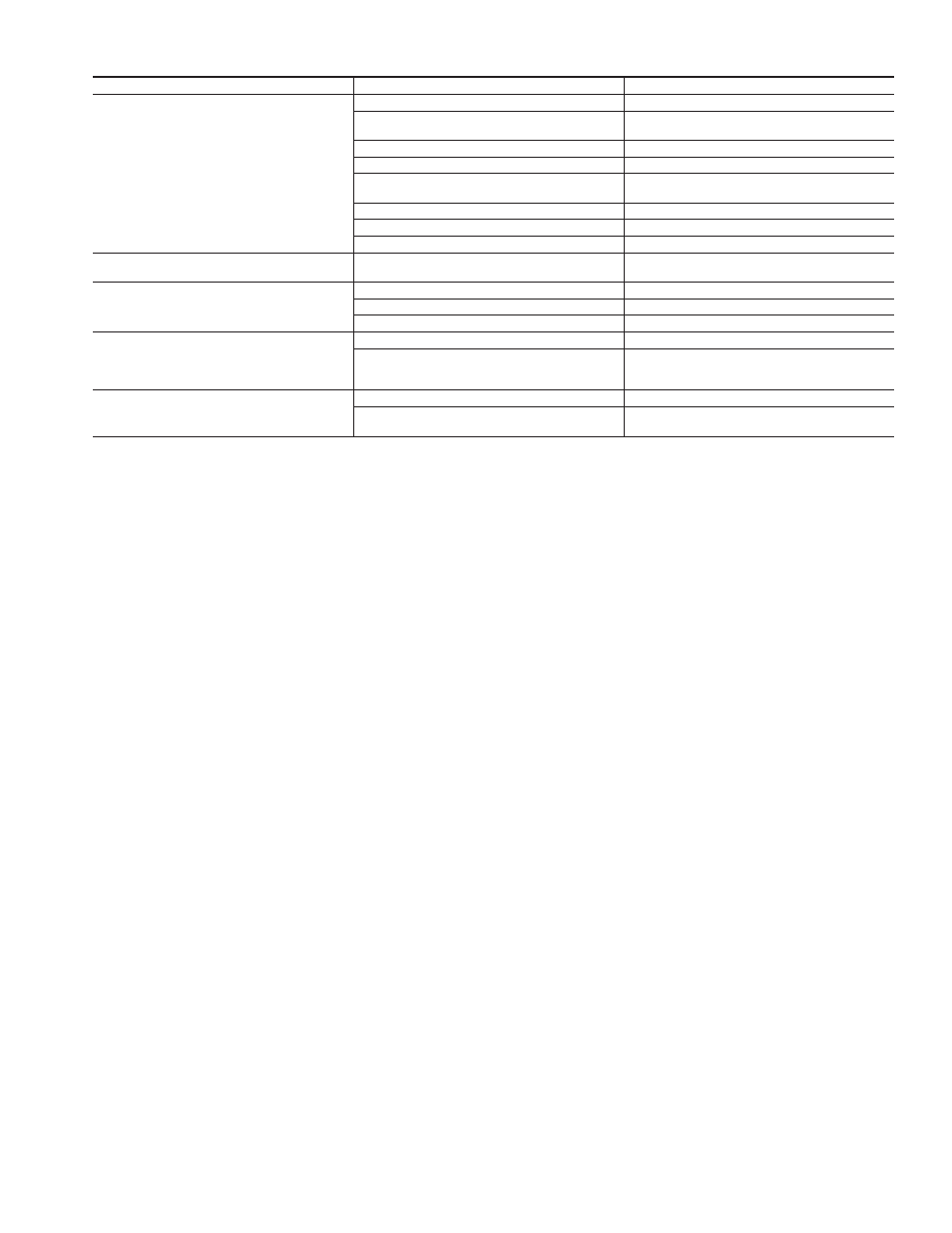

Cooling and Heating Troubleshooting Chart (cont’d)

SYMPTOM

CAUSE

REMEDY

Suction pressure too low

(Cool) Dirty air filter

Replace filter

(Heat) Outdoor coil frosted

Move timer on control board to 30 min. between

defrost cycles

Low refrigerant charge

Check for leaks, repair and recharge

Metering device or low side restricted

Remove source of restriction

(Cool) Insufficient coil airflow

Increase air quantity

Check filter—replace if necessary

(Cool) Temperature too low in conditioned area

Reset thermostat

(Cool) Outdoor ambient below 40°F

Install low-ambient kit

Field-installed filter-drier restricted

Replace

Compressor runs but outdoor fan does not

NC (normally closed) contacts on defrost board

open

Check condition of relay on board

Replace if necessary

IFM does not run

Blower wheel not secured to shaft

Properly tighten blower wheel to shaft

Insufficient voltage at motor

Determine cause and correct

Power connectors not properly sealed

Connectors should snap easily; do not force

IFM runs when it should be off

Motor programmed with a delay profile

Allow a few min. for motor to shut off

With thermostat in off state, the voltage on G,

Y1,Y, Y2, W with respect to common, should be

1/2 of actual low voltage supply

If measured voltage is more than 1/2, the ther-

mostat is incompatible with motor

If voltage is less than 1/2, the motor has failed

IFM operation is intermittent

Water dripping into motor

Verify proper drip loops in connector wires

Connectors not firmly sealed

Gently pull wires individually to be sure they are

crimped into the housing

IFM—Indoor Fan Motor

START-UP CHECKLIST

(REMOVE AND STORE IN JOB FILE)

I. PRELIMINARY INFORMATION

Model No...............................................................................................................................................................................................................

Serial No. ...............................................................................................................................................................................................................

Date ........................................................................................................................................................................................................................

Technician..............................................................................................................................................................................................................

II. PRE-START-UP

___ Verify that all packing materials have been removed from unit

___ Remove all shipping holddown bolts and brackets per installation instructions

___ Verify that condensate connection is installed per installation instructions

___ Check all electrical connections and terminals for tightness

___ Check that indoor (evaporator) air filter is clean and in place

___ Verify that unit installation is level

___ Check fan wheel and propeller for location in housing and setscrew tightness

III. START-UP

Supply Voltage: L1-L2 __________ L2-L3 _________ L3-L1 __________

Compressor Amps: L1 __________ L2 _________ L3 __________

Indoor Fan Amps: __________

TEMPERATURE

Outdoor-Air Temperature: __________ DB

Return-Air Temperature: __________ DB __________ WB

Heat Pump Supply Air: __________

Electric Heater Supply Air: __________

PRESSURES

Refrigerant Suction __________ psig

Refrigerant Discharge __________ psig

___ Verify refrigerant charge using charging tables

___ Verify 3-phase scroll compressor is rotating in correct direction

25