Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 6

Page 6

LAARS Heating Systems

2B. Chimney Venting (USA Only)

Model H(W)-M2-60 and H(W)-M2-100 MUST

NOT BE CHIMNEY OR B-VENT CONNECTED.

Model H(W)-M2-130 is a category l boiler and

may be vented in chimneys subject to the following

requirements:

Chimney must be internally lined or “B” vent

type. EXTERNAL OR UNLINED CHIMNEYS MAY

ONLY SERVE AS A CHASE for utilization of

stainless steel alternative venting providing no other

equipment is vented into it, or the chimney may have

an approved liner installed into the flue.

Two (2) or more vent connectors, from either

power or natural draft units, may enter a common gas

vent providing they conform to the requirements and

tables of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54- latest edition, or applicable provision of the

local building code. None may be connected to

equipment with a positive vent pressure.

Locate unit as close to chimney as possible for

shortest vent connector.

2C. Installation

Determine height of chimney or B-Vent and

length of lateral run. Select vent connector diameter

from:

1). Table 1 or 2 of the National Fuel Gas Code,

ANSI Z223.1 / NFPA 54- latest edition (see

excerpts), or

2). Table G-3 of the Can /CGA - B149 Installation

Code.

Install an adaptor at the flue outlet of the unit to

step up to the diameter of the vent connector. Install

elbow for vent connector, if required. This elbow

should be full size of the vent connector. DO NOT

install a three (3) inch elbow between the flue outlet

on the unit and the adaptor. DO NOT use plastic vent

pipe in any part of the chimney vent connection.

Install vent connector between elbow, if used,

and chimney. Pitch vent connector up toward chimney

¼" per foot of lateral run. Secure all joints with

sheetmetal screws.

2D. Alternate Venting Method

(Canada Only)

The H Series may be vented vertically up

through a masonry chimney using a 4" diameter ULC

Certification Flexible Stainless Steel Vent.

Observe the following requirements:

1). The flexible vent must be run from the boiler up

through the entire chimney.

2). The chimney must terminate with a suitable vent

cap.

3). If chimney is exposed, the vent pipe should be

insulated.

4). The vent pipe must be installed with a ¼" per

foot upward slope from the boiler to the

chimney.

5). The vent pipe must be supported every 3' to

prevent sagging.

6). All joints in the vent must be secured with at

least two corrosion resistant screws and sealed

with an approved silicone sealant and checked

for gas tightness.

7). The vent system should be checked once a year

by a qualified serviceman.

Note: Boiler may not be vented in common with

another gas appliance or be vented using B-vent.

SUPPLY

DOMESTIC

RETURN

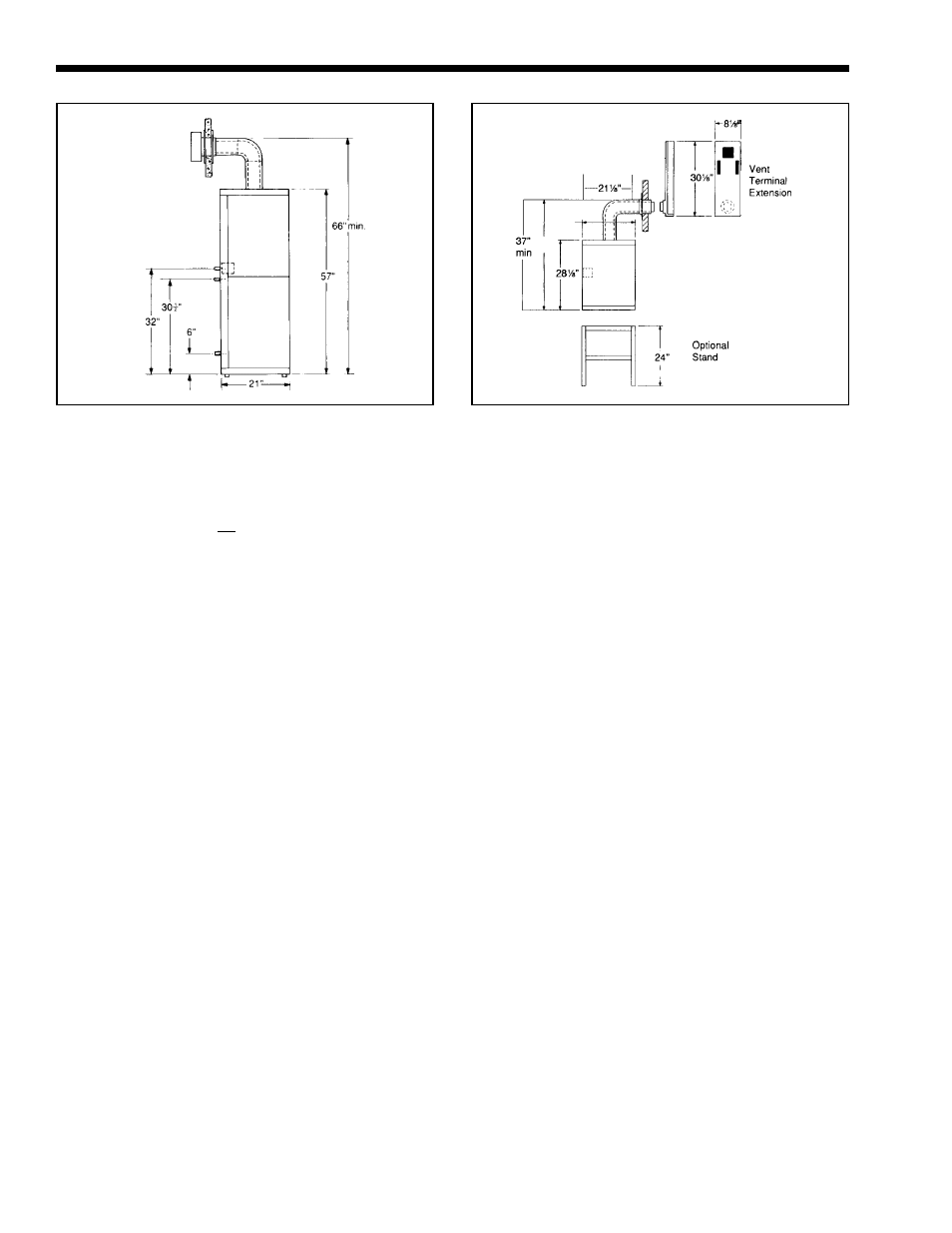

Figure 3. HW-M2.

↑

3.5" deep

Figure 4. H-M2.

OUT OF

PRODUCTION