Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 13

H Series

Page 13

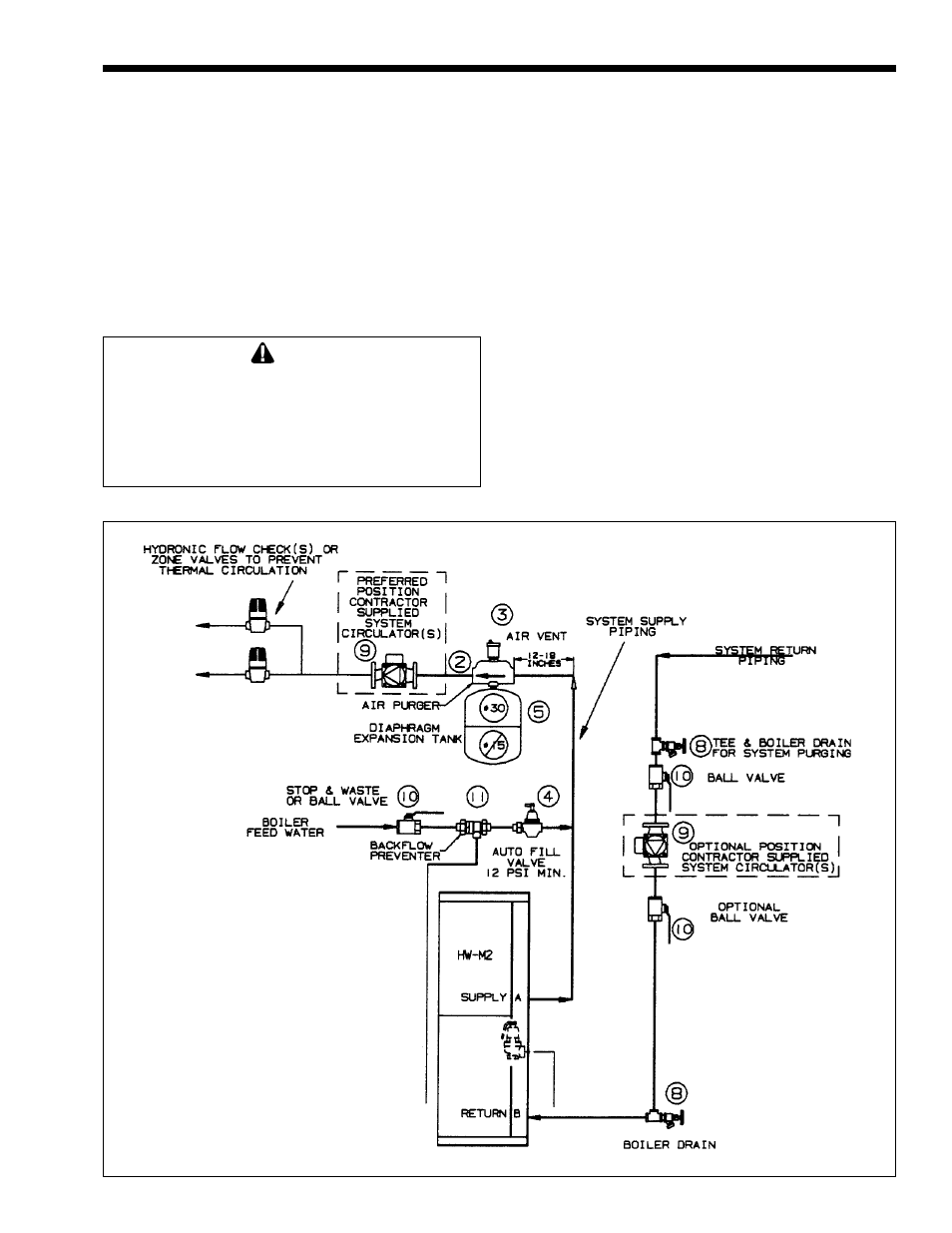

5C. Hydronic Piping - HW Series

HW-M2 boilers are installed in single and

multiple zone systems ( using either zone valves or

zone circulators) in the same manner as any other

residential boiler. Systems with zone circulators or

single zone systems require the installation of a

hydronic flow check (6) to prevent gravity circulation

of heating supply water when no heat is desired.

To minimize heat loss from the storage tank

(HW) during standby periods, it is recommended that

the piping between the H Series up to and including

the vertical leg be insulated with ½" - ¾" of insulation.

Caution

Unless equipped with optional stainless steel tank,

the HW model must not be direct connected to a

heating system utilizing oxygen permeable tubing,

(see warranty). Provide a water to water heat

exchanger between systems to prevent corrosion of

tank or other components.

Nontoxic heating system antifreeze may be

added to the hydronic system provided that the

concentration does not exceed 35% and the antifreeze

contains an anti-foamant.

5D. Using In a Combined Hot Water

Heating and Chilled Water Cooling

System

When the H Series is used in connection with a

refrigeration system, it must be installed so that the

chilled medium is piped in parallel with the boiler

with appropriate valves to prevent the chilled medium

from entering it.

The boiler piping system of a H Series boiler

connected to heating coils located in air handling units

where they may be exposed to refrigerated air

circulation must be equipped with flow control valves

or other automatic means to prevent gravity

circulation of the boiler water during the cooling

cycle.

Figure 14. Hydronic Piping (HW).

OUT OF

PRODUCTION