Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 5

H Series

Page 5

1C. Codes and Standards

All installations must be made in accordance

with: 1). The National Fuel Gas Code, ANSI Z223.1 -

latest edition or 2). CAN/CGA - B149 “Installation

Codes for Gas Burning Appliances and Equipment” or

with the requirements of the local utility or other

authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein. All electrical wiring is

to be done in accordance with 1). The National

Electrical Code ANSI/NFPA70-latest edition or 2).

The CSA standard C22.1 “Canadian Electrical Code -

Part 1” and local codes.

All vent installations must be made in

accordance with: 1). Part 7, Venting of Equipment of

the National Fuel Gas Code, ANSI 223.1- latest

edition, or applicable provisions of the local building

codes or 2). CAN/CGA - B149

When required by the jurisdiction authority, the

installations must conform to the American Society of

Mechanical Engineers’ Safety Code for Controls and

Safety Devices for Automatically fired Boilers, No.

CSD-l.

1D. Unpacking the H Series

a.

Remove all packing and tie down materials.

b.

On HW models, remove three (3) shipping bolts

from underside of base.

c.

Make immediate claims ( to carrier ) if unit is

damaged.

1E. Locating the H Series

The H Series design is certified by the AGA and

CGA for installation on combustible flooring, in

alcoves, basements, closets, or utility rooms. It must

not be installed on carpeting. IF INSTALLED IN A

FINISHED AREA, PROVISION SHOULD BE

MADE FOR DRAINAGE OF ANY ACCIDENTAL

SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with

regard to venting dimensions, convenient access to

piping, ventilation of operating components and

accessibility for service and cleaning.

The boiler shall be installed so that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

1F. Clearances

The following dimensions and criteria should be

followed when choosing the location for the unit:

Õ

h

j

k

l

Ö

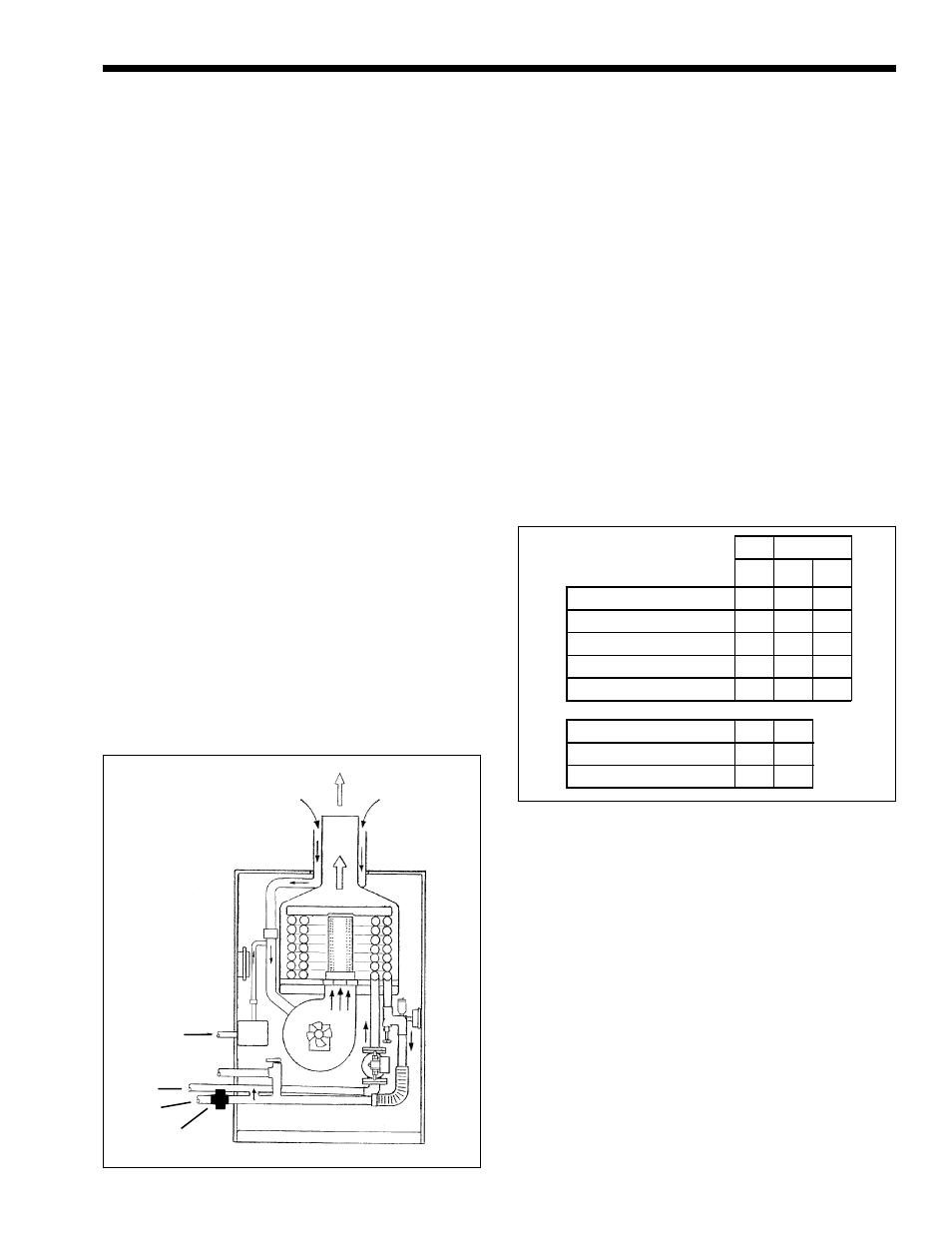

Figure 2. H-M2.

A.

B.

AGA/

CGA

AGA

CGA

Left Side

1"

6"

24"

Right Side (controls)

1"

12"

24"

Top

1"

14"

16"

Back

1"

9"

12"

Front

1"

24"

24"

Vent: Direct Vent

0"

0"

Chimney Connect

6"

6"

Alternate

3"

3"

Clearances

A.

Minimum clearance from combustible

construction to meet AGA/CGA requirements.

B.

Recommended clearance for accessibility and

venting.

SECTION 2.

Venting Options

2A. Locating Unit With Respect

to Ventilation

While the H Series, when direct vented, requires

no interior air for combustion, adequate airflow

around the unit and to the enclosed room must be

provided for proper cooling of electrical components.

OUT OF

PRODUCTION