Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 10

Page 10

LAARS Heating Systems

SECTION 3.

Venting and Air Source

3A. The Direct Vent Kits

(part numbers 2400-326 or 2400-328)

When using the Direct Vent Kit, the H Series is a

sealed combustion unit. All of its air is drawn in from

the outside through the 5" outer pipe. Flue gases are

vented through the 3" vent pipe positioned inside the

5" intake pipe. The hot flue gases are surrounded by

the intake flow of cooler outdoor air. This vent system

may be installed through, and be in contact with,

combustible materials.

3B. Installing Direct Vent Kits

The Direct Vent H Series is certified with a

maximum of 15 linear feet of vent pipe and one set of

elbows. Systems may be vented with a maximum of

three sets of concentric elbows providing the

maximum length is reduced by three linear feet for

each additional elbow set. Provide a minimum of 16"

above the top of the boiler for vent installation and

servicing. There are two vent kits available. Part

numbers 2400-326 and 2400-328 provides all of the

required materials. Part number 2400-326 for vent

installations which require adjustable height and

horizontal run. This kit will permit vertical and

horizontal lengths of pipe from 2' or 4'. One foot

extensions and 2' to 4' extensions are available to

increase vent lengths to the maximum allowed.

Additional sets of elbows are also available.

Part number 2400-328 provides all of the

required materials for vent installations which may

have a fixed height of 11 inches and an adjustable

horizontal run of 2' - 4'. Accessories for P/N 2400-326

also fit P/N 2400-328.

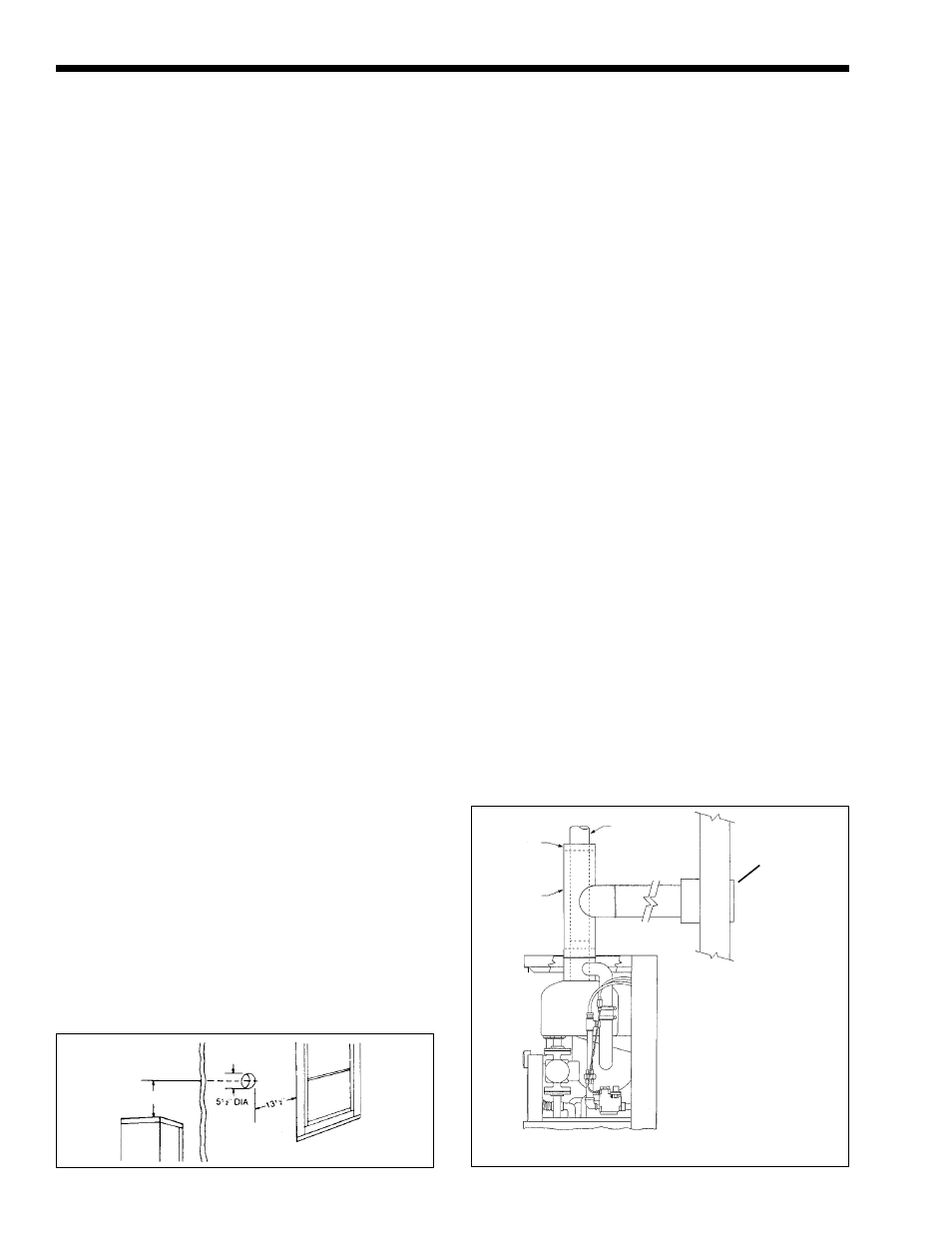

3C. Locating the Vent on an Outside Wall

Exterior vent should terminate 16½" above

grade, and at least 13 ½" from any other building

opening such as doors, windows, etc. Units

terminating below the top of the boiler must reduce

allowable vent length by 1" for every foot of vertical

drop below the top.

Vent opening should be well away from

shrubbery or other obstructions that would prevent

free air flow to and from vent terminal. Do not

terminate vent under decks, stairways, or car ports.

When ever possible, locations under windows should

be avoided.

NOTE: Should it be impossible to locate

opening center line 16 ½" above grade, use optional

Vent Terminal Extension (Part Number 2400-278).

(see Figure 4).

Vent terminals must also be at least 3' above any

forced air inlet located within 10', and at least 7' above

grade when located adjacent to a public walkway, and

cannot terminate in a location where condensate or

vapor may be a nuisance, hazard, or could be a

detriment to other equipment. Vent terminals must

have a minimum clearance of 4 feet horizontally from,

and in no case above or below electrical meters, gas

meters, regulators, and relief equipment unless a 4 foot

horizontal distance is maintained .

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products could

strike against building materials and cause degradation.

3D. Air Source For Combustion

(when not direct vented)

When using these venting methods the H Series

draws all combustion air through the top of the unit

and from the space around the boiler. When locating

the unit in unconfined spaces in buildings, infiltration

may be adequate to provide air for combustion and

ventilation; however, in buildings of unusually tight

construction, or when locating the unit in a confined

space, additional air should be provided and the

following guidelines must be followed.

1.

If the space is in a building of unusually tight

construction, air should be obtained from

outdoors, or from spaces which freely connect

with outdoors.

INTAKE AIR

SCREEN

PLUG

5" TEE

3" VENT

4" MIN. DIA

H, HP or HW with

Separate Air

Source.

ALTERNATE TO 1. - 3. ABOVE

Figure 11. H, HP or HW with Separate Air Source.

8" MIN.

Figure 10. Direct Vent Terminal Clearance.

OUT OF

PRODUCTION