Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 11

H Series

Page 11

2.

For boilers in confined rooms, two permanent

openings shall be provided - one within 12" of

the ceiling, and one within 12" of the floor of

each room. Each opening shall be at least one

square inch per 1,000 BTU/HR boiler input, but

not be less than 100 square inches. These

openings shall freely connect with areas having

adequate infiltration from outside.

3.

When all air is provided from outdoors, the

confined space shall be provided with two

openings as outlined above. These openings shall

connect directly, or by ducts, with outdoors or

spaces (crawl or attic) that freely connect with

the outdoors, and shall be of the size listed below

for that particular arrangement.

a.

One square inch of free area per 4,000

BTU/HR of boiler input for direct outdoor

air supply through an outside wall, or

through vertical ducting directly to outside.

b.

One square inch of free area per 2,000

BTU/HR of boiler input for direct outdoor

air through horizontal ducting.

c.

All ducting shall be of the same size as the

opening to which it is connected.

SECTION 4.

Gas and Domestic Water Piping

4A. Gas Connection to H Series

The H Series requires an inlet gas pressure of at

least 4" W.C and no greater than 13" W.C. Check with

your local gas utility or supplier for availability of this

pressure range.

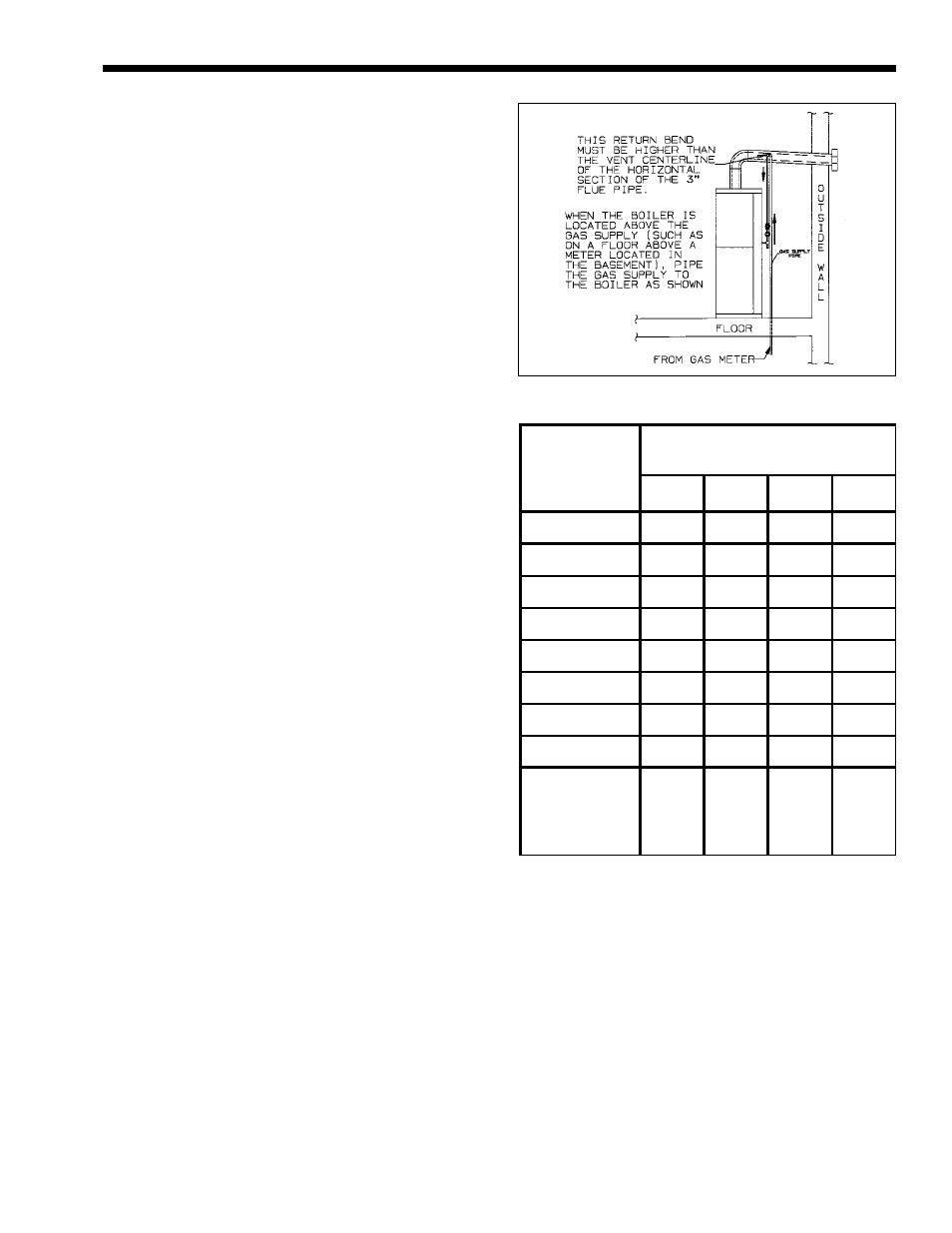

Referring to Table 4, size supply piping to

minimize pressure drop between meter or regulator

and unit.

Run gas supply line in accordance with all

applicable codes. IF UNIT IS INSTALLED ABOVE

GAS SUPPLY, RUN PIPPING UP TO A POINT

ABOVE VENT CENTER LINE AND BACK DOWN

TO UNIT. THIS WILL PREVENT WATER FROM

ENTERING GAS SUPPLY SHOULD A LEAK

DEVELOP IN THE BOILER SECTION (see

Figure 12).

Locate and install manual shutoff valves in

accordance with state and local requirements.

Install drip leg, ground joint union and drip cap

to trap sediment and for test gauge access (see

Figure 12).

Support all piping with proper hangers.

All threaded joints should be coated with piping

compound resistant to action of liquefied petroleum

gas whether LPG is used or not.

The boiler and its individual shutoff valve must

be disconnected from the gas supply piping system

Figure 12. Gas Piping.

Length

of

Pipe

Capacity of Pipe in MBTU / HR

(.6 Specific Gravity)

½"

¾"

1"

1¼"

10'

132

278

520

1,050

20'

92

190

350

730

30'

73

152

285

590

40'

63

130

245

500

50'

115

215

440

75'

93

175

360

100'

79

150

305

150'

64

120

250

Additional

length to be

added for each

tee or bend

1.3'

1.7'

2.2'

2.7'

Table 4. Gas Pipe Capacity.

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa).

The boiler must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5kPa).

The boiler and its gas connection must be leak

tested before placing the boiler in operation.

Purge all air from gas lines.

Note: H Series’ are certified for 4" to 13" W.C.

We find on L/P the unit performs better when the low

pressure regulator is not set over 9" W.C. Use an

appliance regulator (maxitrol RV48 or equivalent) if

more than 3" lock up occurs in gas supply.

OUT OF

PRODUCTION