Out of production – LAARS HP-M2 Series - Installation, Operation and Maintenance Instructions User Manual

Page 12

Page 12

LAARS Heating Systems

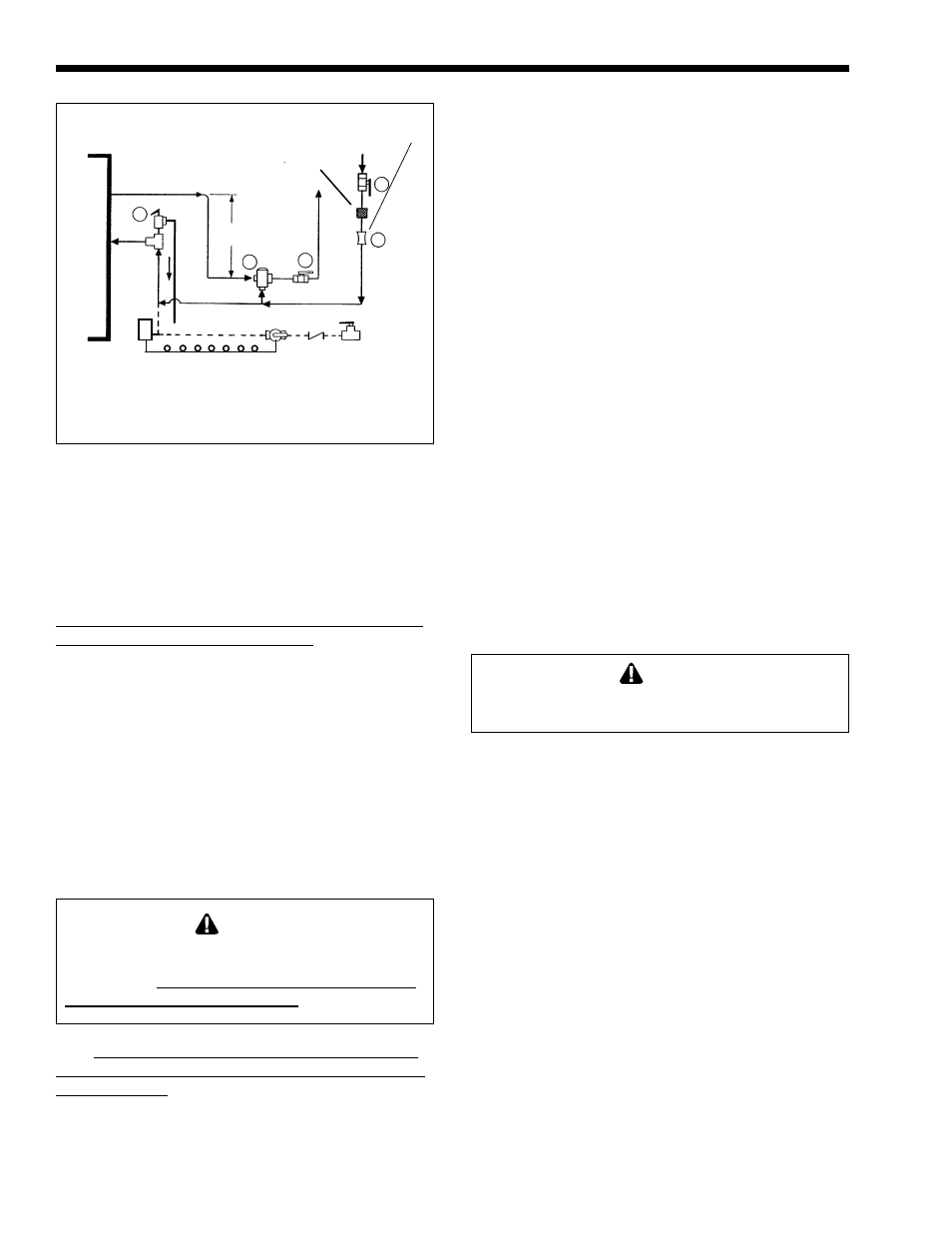

4B. Domestic Water Piping

Connect hot water tempering valve (12) “HOT”

port to hot water outlet from unit. This valve should be

mounted 3" to 6" below the outlet and set for 120° F

mixed delivery temperature or as local codes dictate.

H SERIES RECOMMENDS ANTI SCALD VALVE

SUCH AS SPARCO OR DANFOSS. (see Figure 13).

Connect gate or shutoff valve (13) to tempering

valve (12) “MIX” port, and cold water inlet.

Install supplied flow restrictor (14) ahead of mix

valve tee.

Connect pressure relief valve (1) (if required by

codes), maximum 150 PSI as close to the unit as

possible. No other valves or restrictions may be

installed between the H Series and the relief valve.

(DO NOT USE A TEMPERATURE/

PRESSURE RELIEF VALVE AS THIS IS NOT A

STORAGE HOT WATER HEATER).

*Model 60 is not recommended for larger hot

water demands.

WARNING

Failure to install a hot water tempering valve (12)

creates a scalding hazard with potential for serious

bodily injury. Some brands of tempering valves are

not designed as anti scold valves.

Installations with water containing 10 grains of

hardness or higher, must be installed with appropriate

water treatment.

SECTION 5.

Hydronic Heat Piping

5A. Hydronic Heat Piping

Hydronic Connections, Fittings and Accessories

(see Figure 16).

NOTE: A SEPARATE HEATING

CIRCULATOR MUST BE PROVIDED IN

SYSTEM PIPING, FOR ALL MODELS.

Connect system supply to 1" supply connection (A).

1.

Install thermostatic union (supplied) on H, HP

boilers.

2.

Pipe the discharge of the relief valve, full size, to

a drain or in a manner to prevent injury or

property damage in the event of pressure relief.

3.

Install an air purger (2) in supply line.

4.

Install automatic float type air vent (3) on air

purger.

5.

Connect diaphragm type expansion tank (5) to

air purger.

6.

Install a boiler drain valve (8) adjacent to unit in

return line.

7.

Connect system return to 1" return connection (B).

8.

Install a properly sized circulator (9) with

optional isolation valves (10).

Caution

All hot water pipes must be installed with a

minimum 1" clearance from combustible materials.

NOTE: H, HP boilers installed in radiant (in

floor) systems and other low mass systems should be

provided with a buffer tank to assure constant supply

temperature without excessive boiler short cycling

(see Figure 17).

5B. Feed Water Make-Up

Connect boiler feed water supply with shut off

valve to inlet connection of automatic fill valve (4).

If codes require, install suitable back-flow

preventor (11) between automatic fill valve and city

main.

To ensure sufficient expansion volume of the

hydronic system water due to heat-up and cool-down

during normal operation, a #30 or larger expansion

tank must be used on all HW series applications.

H

E

A

T

M

A

K

E

R

12

1

13

13

14

15

CIRCULATOR

OPTIONAL RETURN LINE PIPING

AQUA-

STAT

WATER

SOFTENER

SUPPLIED

6"*

* or per valve manufacturers instructions.

Figure 13. Domestic Water Piping.

OUT OF

PRODUCTION