Heat pump controls compressor protection, Crankcase heater, Commercial defrost control – Carrier 38AUQ User Manual

Page 22

22

Heat Pump Controls

Compressor Protection

Compressor Overcurrent

The compressor has internal limbered motor protection.

Compressor Overtemperature

The compressor has an internal protector to protect it against

excessively high discharge gas temperatures.

High Pressure Switch

The system is provided with a high pressure switch mount-

ed on the discharge line. The switch is stem-mounted and

brazed into the discharge tube. Trip setting is 630 ± 10 psig

(4344 ± 69 kPa) when hot. Reset is automatic at 505 ± 20

psig (3482 ± 140 kPa).

Loss of Charge Switch

The system is protected against a loss of charge and low

evaporator coil loading condition by a loss of charge switch

located on the liquid line and a freeze protection thermostat on

the indoor coil. The switch is stem-mounted. Loss of Charge

Switch trip setting is 27 psig ± 3 psig (186 ±21 kPa). Reset is

automatic at 44 ±5 psig (303 ± 35 kPa).

Outdoor Fan Motor Protection

The outdoor fan motor is internally protected against overtem-

perature.

Control Circuit, 24-V

The control circuit is protected against overcurrent conditions

by a circuit breaker mounted on control transformer TRAN.

Reset is manual.

Crankcase Heater

The heater prevents refrigerant migration and compressor oil

dilution during shutdown whenever compressor is not operat-

ing. The heater is wired to cycle with the compressor; the heat-

er is off when compressor is running, and on when compressor

is off.

The crankcase heater will operate as long as the power circuit

is energized.

Commercial Defrost Control

The Commercial Defrost Control Board (DFB) coordinates

thermostat demands for supply fan control, 1 or 2 stage

cooling, 1 or 2 stage heating, emergency heating and defrost

control with unit operating sequences. See Fig. 22 for board

arrangement.

The DFB is located in the 38AUQ's main control box (see

Fig. 21). All connections are factory-wired. Refer to Table 12

for details of DFB Inputs and Outputs.

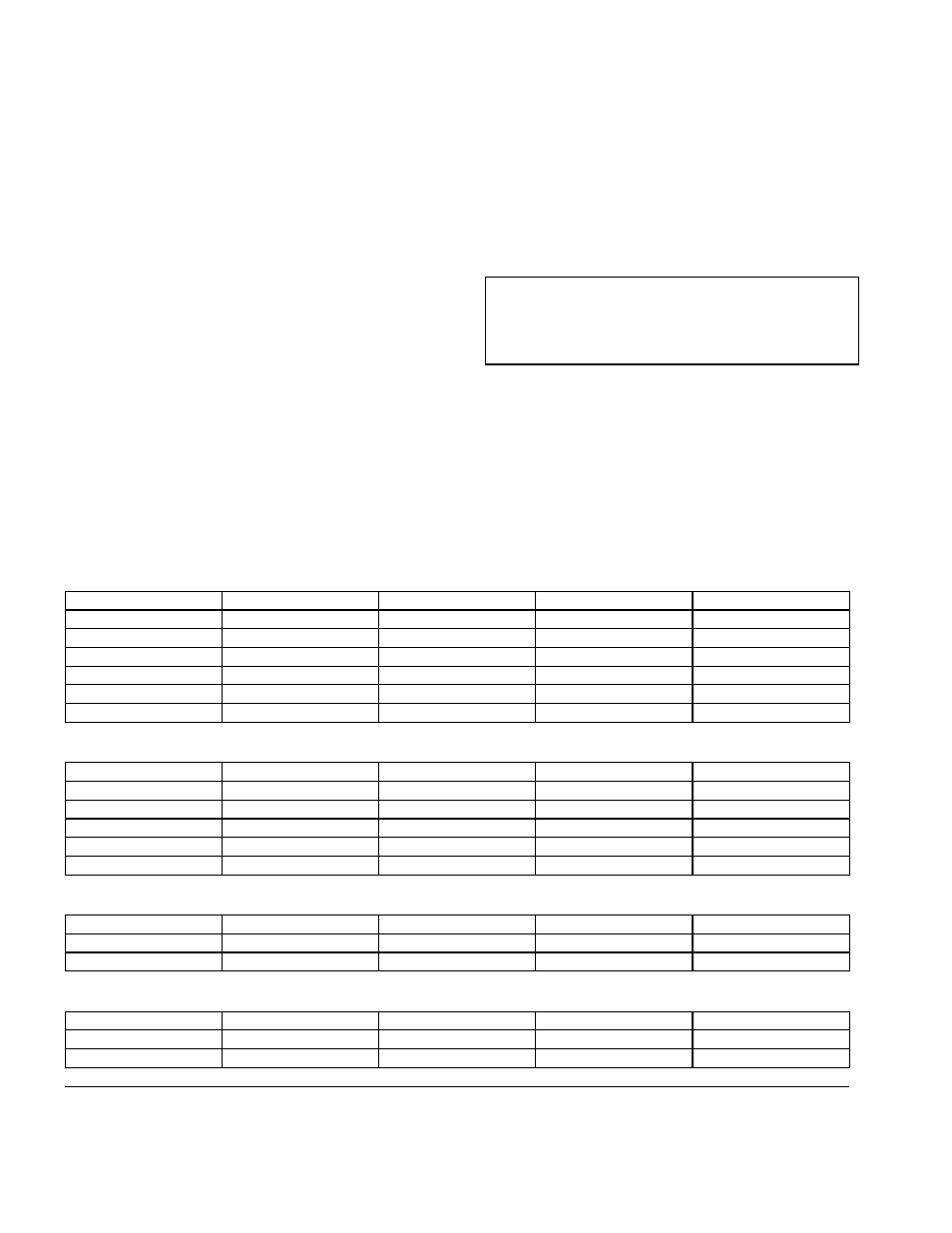

Table 12 —38AUQ Defrost Board I/O and Jumper Configurations

IMPORTANT: Never open any switch or disconnect that

energizes the crankcase heater unless unit is being serviced

or is to be shut down for a prolonged period. After a pro-

longed shutdown on a service job, energize the crankcase

heater for 24 hours before starting the compressor.

Inputs

Point Name

Type of I/O

Connection Pin Number

Unit Connection

Note

G Fan

DI, 24-vac

P2-3

Not used

Y1 Cool 1

DI, 24-vac

P2-5

TB-Y1

Wi Heat 1

DI, 24-vac

P2-7

TB-W1

R Power

24-vac

P3-1

TRAN2

C Common

24-vac, ground

P3-3

TRAN2

DFT1 Defrost Switch

DI, 24-vac

DFT-1 to DFT-1

DFB

Outputs

Point Name

Type of I/O

Connection Pin Number

Unit Connection

Note

OF OD Fan

DO, 24-vac

OF

OFR

RVS1

DO, 24-vac

P3-7 to P3-5

RVS1

Energize in COOL

RVS2

DO, 24-vac

P3-6 to P3-4

RVS2

Energize in COOL

COMP 1

DO, 24-vac

P3-10

CADM1-Y

HEAT 2

DO, 24-vac

E-HEAT

HC-1 (TB4-1)

Configuration

Point Name

Type of I/O

Connection Pin Number

Unit Connection

Note

Select Jumper

24-vac

P1-1

1 Compressor

24-vac

P1-2

Speed-Up Configuration

Point Name

Type of I/O

Connection Pin Number

Unit Connection

Note

Speed-Up Jumper

JMP17

Speed-Up Jumper

JMP18

Jumper for 1-3 secs: Factory Test, defrost runs for 12 seconds or less

Jumper for 5-20 secs: Forced Defrost, defrost runs for 30 secs if DFT2 is open