Great Planes Yak-54 1.60 ARF - GPMA1411 User Manual

Page 18

❏

11. Apply heat to the heat-shrink tubing on the cables.

Slide the heat-shrink down the cables toward the tail,

centering the pieces on the location where the cables cross

each other. This will prevent the metal cables from rubbing

against each other which could cause radio interference.

With the heat-shrink tubes in place, use medium CA glue to

adhere the heat-shrink to the cables. Be careful not to glue

the heat-shrink tubes to each other.

❏

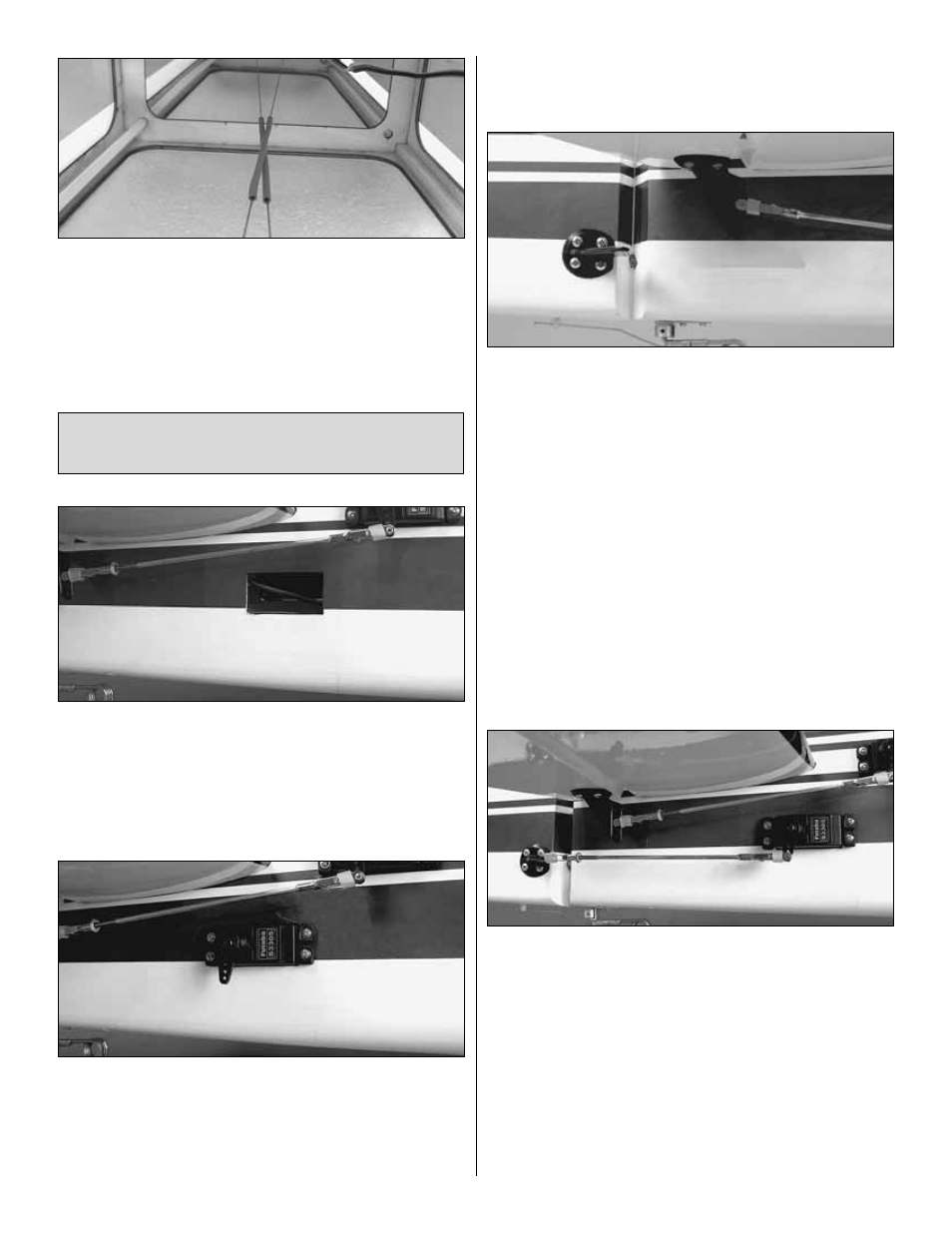

1. Locate the cutouts for the rudder servos on both sides

of the fuselage beneath the horizontal stabilizer. Cut the

covering 1/8" [3 mm] inside the openings. Use a trim iron to

seal the covering to the inner edges of the opening.

❏

2. Attach a 36" [914 mm] servo extension to each elevator

servo. Secure the connections with heat-shrink tubing.

❏

3. Temporarily position the rudder servos into the servo

bays. Drill a 1/16" [1.6 mm] hole through the four mounting

holes of each servo, drilling through the plywood mounting

plates in the fuselage. Install and remove a servo mounting

screw into each of the eight holes. Apply a drop of thin CA

into the holes to harden the wood. After the glue has cured,

install the servos into the openings using the hardware that

came with your servos. Center the servos with your radio

system and install servo arms as shown.

❏

4. Just as you did with the ailerons, look closely on the

sides of the rudder and you will notice a plywood plate

visible under the covering. Place a heavy-duty nylon control

horn on each side of the rudder, positioning it as shown and

aligning it with the outer hole of the servo arm. Mark the

location for the screw holes. Drill through the marks you

made with a 3/32" [2.4 mm] drill bit. (Be sure you are drilling

into the plywood plates mounted in the rudder. Drill through

the plate only. Do not drill all the way through the rudder!)

Using a #4 x 5/8" [16 mm] sheet metal screw, install and

then remove a screw into each of the holes. Harden the

holes with thin CA. Install the control horns with eight #4 x

5/8" [16 mm] sheet metal screws.

❏

5. Locate two .095" x 12" [2.4 x 305 mm] pushrod wires

threaded on one end. Thread a 4-40 nut, a silicone clevis

retainer and a threaded metal clevis onto the threaded ends

of the wires 20 turns. Tighten the nut against the clevis and

then install the clevis on the rudder control horns.

❏

6. Be sure the rudder servos are centered (with the arms

pointing down). Install a 4-40 metal solder clevis onto the

outer most hole in each servo arm. Center the servo arms

and center the rudder. Using the solder clevis as a guide,

mark where to cut the pushrod wire. Remove the pushrods

and clevises from the control horns and the solder clevises

from the servo arms. Cut the pushrod to length, install

another silicone clevis retainer, and solder the clevises to

the pushrods.

Install the Rudder Servos & Linkage

(Recommended Gas Engine Installation)

18