Great Planes Yak-54 1.60 ARF - GPMA1411 User Manual

Page 17

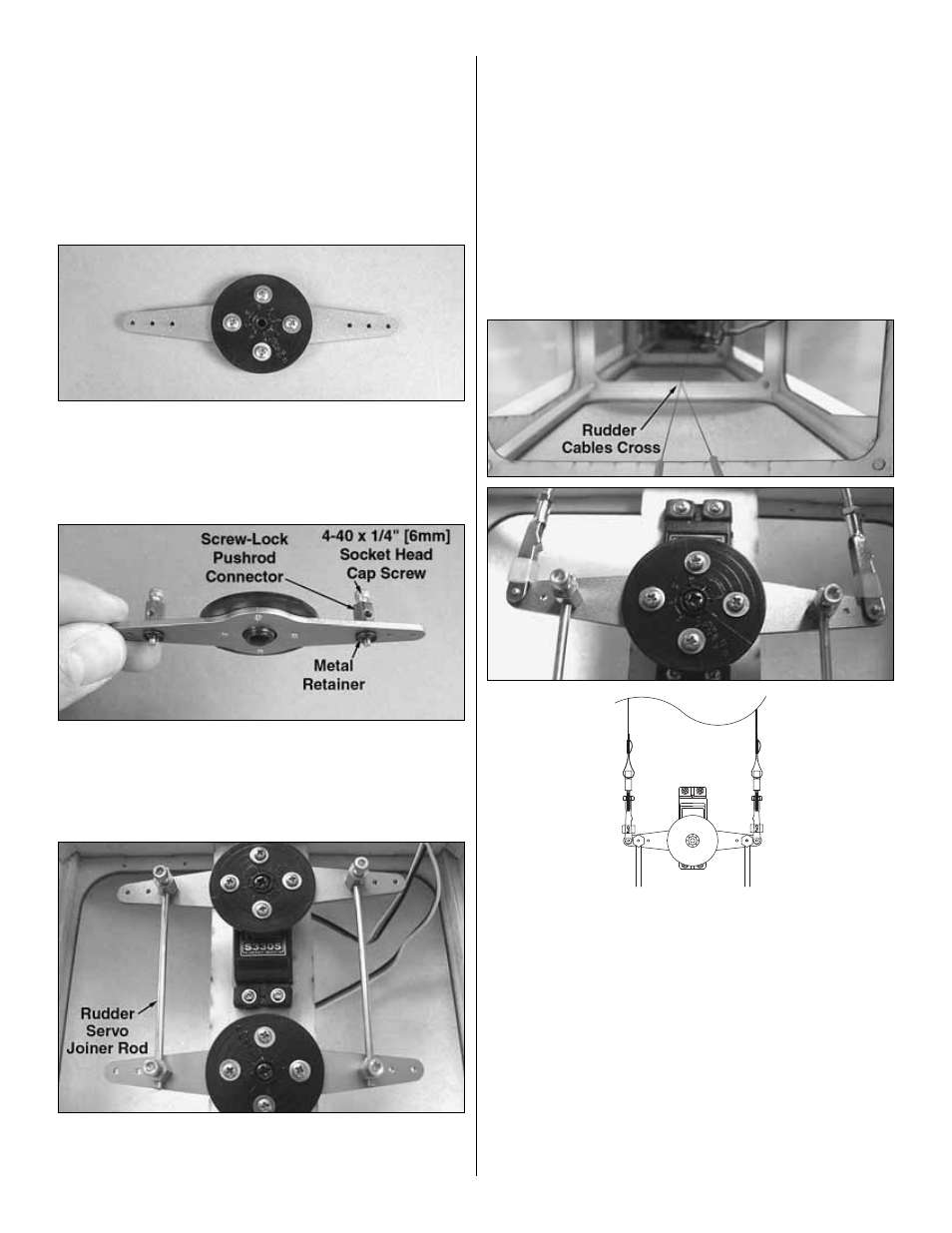

wheels included with the rudder servos (Different model

servos may come with servo wheels that are larger or smaller

than the ones shown in the picture. The actual size of the servo

wheels being used is not critical.) Fit the aluminum servo

extensions to the undersides of the servo wheels and tape

them in place. Use a 1/16" [1.6mm] drill bit to drill through the

four mounting holes in the servo extensions into the plastic

servo wheels. Remove the servo wheels from the extensions

and enlarge the holes with a 3/32" [2.4mm] drill bit.

❏

7. Using eight 2-56 x 3/8" [9.5 mm] Phillips screws and

eight #2 flat washers, attach the servo extensions to the

servo wheels. Apply a drop of thread-locking compound to

each screw. With a cut-off wheel, cut off the ends of the

screws that protrude from underneath the servo extensions.

❏

8. Drill out the inner holes of both servo extensions using a

7/64" [2.8 mm] bit. Do not use any other size drill bit for this step.

Secure a screw-lock pushrod connector to each arm in the holes

you just drilled out with a metal retainer. Thread four 4-40 x 1/4"

[6 mm] SHCS loosely into the screw-lock pushrod connectors.

❏

9. With the servos centered, align the servo arms

perpendicular with the fuselage and parallel with each other

and secure them to the rudder servos with the servo arm

screws. Insert the two rudder servo joiner rods (included

with the kit), through the screw-lock pushrod connectors as

shown and tighten the 4-40 x 1/4" [6 mm] SHCS. Use wire

cutters to cut away the excess joiner rod length.

❏

10. Connect the other two clevis ends with the brass

couplers installed onto the outer holes of the aft rudder

servo arm. Check to be sure that the elevator servo wires

are not entangled in the rudder pull-pull cables. Slide a 3"

[76 mm] piece of 1/8" [3 mm] heat-shrink tubing and then a

swage onto the ends of the pull-pull cables inside the

fuselage. Move the rudder to the neutral position and feed

the ends of the cables through the holes in the couplers. The

pull-pull cables will cross each other inside the fuselage.

With both pull-pull cables having tension and the rudder in

the neutral position, crimp the swages onto the cable ends

to secure them as you did in step 4. You can fine-tune the

tension on the lines by threading the clevises up or down on

the couplers until satisfied. Then, tighten the 4-40 nuts

against the clevises.

17