Great Planes Yak-54 1.60 ARF - GPMA1411 User Manual

Page 14

❏

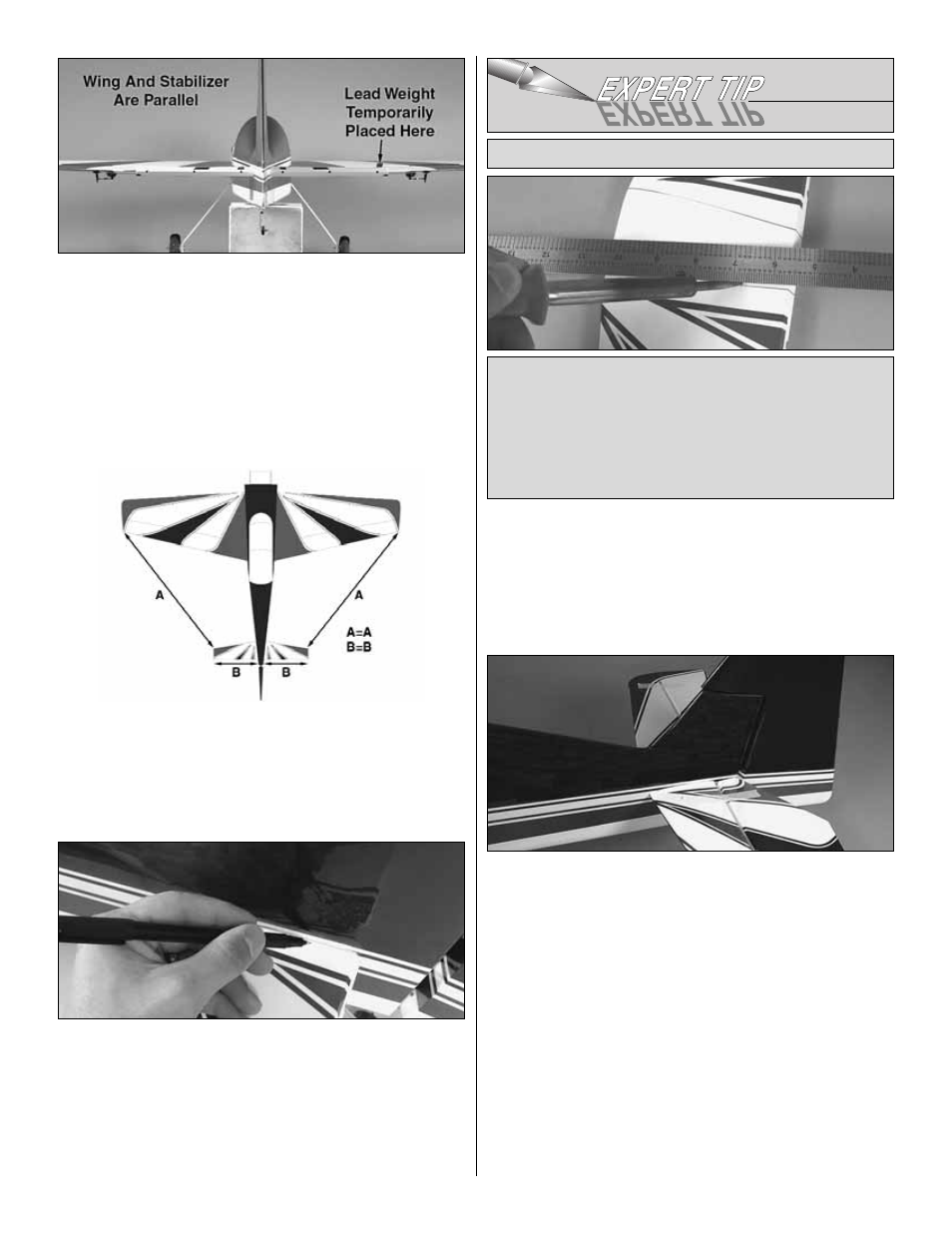

5. Test fit the stabilizer in the fuselage. Center the stab left

and right in the fuselage. Stand back 15 to 20 ft [5 to 6 m] and

check to be sure the stab is parallel to the wing. Adjust the stab

saddle as needed until the stab and wing are parallel. If

necessary, weight can be added to one side of the stabilizer as

shown above to bring the stab parallel to the wing. When the

stab is glued in place permanently, the same amount of weight

will be added temporarily while the epoxy cures.

❏

6. Measure the distance from the tip of each wing to the

tip of the stab. Adjust the stab until the distance from the tip

of the stab to the tip of the wing is equal on both sides.

Center the stab in the fuse left and right.

❏

7. Use a felt-tip marker to mark the outline of the fuselage

onto the top and bottom of the stab.

❏

8. Remove the stab from the fuse. Use a sharp #11 hobby

knife or use the following

Expert Tip to cut the covering

1/16" [1.6 mm] inside of the lines you marked. Use care to

cut only in the covering and not into the wood.

❏

9. Use 30-minute epoxy to glue the stab into the fuselage.

For the most strength, apply epoxy to both sides of the stab

and inside the fuse where the stab fits. Slide the stab into

position. Wipe away any excess epoxy with a paper towel

and denatured alcohol. Do not disturb the model until the

epoxy has fully hardened.

❏

10. Mix up 1/4 oz. [7.5 cc] of 30-minute epoxy. Using a

toothpick or wood scrap, apply epoxy to the inside of each

hinge point hole. Apply a light coat of epoxy to one end of all

the hinges for the elevators. Insert the hinge points into the

holes, wiping away excess epoxy with a paper towel and

denatured alcohol. Be sure the hinges are inserted in the

correct orientation. Apply epoxy to the other ends of the

hinges and slide the elevators into place. Use masking tape

to hold the elevators in position while the epoxy cures.

Use a soldering iron to cut the covering from a balsa

sheeted surface. The tip of the soldering iron doesn’t have

to be sharp, but a fine-tip does work best. Allow the iron to

heat fully. Use a straightedge to guide the soldering iron at

a rate that will just melt the covering and not burn into the

wood. The hotter the soldering iron, the faster it must

travel to melt a fine cut. Peel off the covering.

How to cut covering from balsa

14