Great Planes Seawind .60-.91 ARF - GPMA1360 User Manual

Page 15

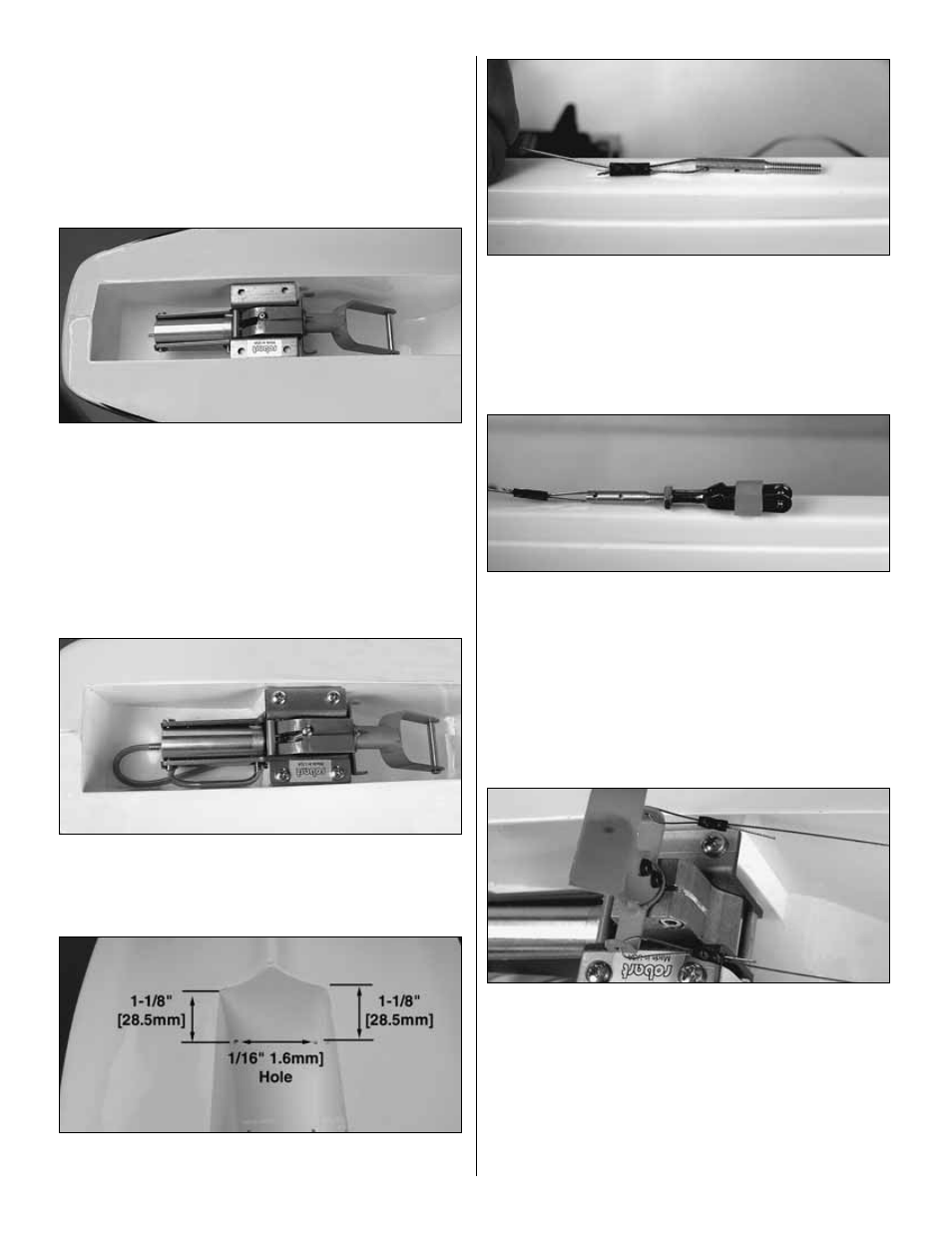

line tubing on the main retracts. Position the main retract in the

wing so that the wheel is centered in the wheel well. Use a felt-

tip pen to outline the mounting flanges of the main retracts.

Use a sharp hobby knife to cut and remove balsa sheeting

over the hardwood mounting rails. Reinstall the main retracts

in the wing and secure them to the plywood rails with the

screws included with the main retracts.

❏ ❏

10. Position the nose gear retract on the landing gear rail.

❏ ❏

11. Determine the best location for the air line tubing to

come through the wheel well and drill a hole to route the air

line tubing through. Connect the air line tubing to the retract

and the control valve.

❏ ❏

12. Mount the nose gear retract in the fuselage with the

screws included with the main retract.

❏

13. Drill a 1/16" [1.6mm] hole in both of the aft corners,

1-1/8" [28.5mm] from the bottom of the fuselage.

❏ ❏

14. Put a piece of masking tape on the end of one of

the metal cables. Insert the cable in one of the holes. The

masking tape will prevent the cable from pulling through the

hole. Slide a metal furl on the cable inside the fuselage. Then

thread the cable through the bottom hole in the threaded

coupler and then back through the furl. Use a pliers to crimp

the furl on the cable.

❏ ❏

15. Install a 2-56 nut half-way onto the threaded coupler.

Install a silicone clevis retainer on a 2-56 threaded metal

clevis. Install the clevis on the threaded coupler and tighten it

against the 2-56 nut.

❏ ❏

16. Attach the clevis in the outer hole of the steering

servo arm.

❏

17. Return to step 14 and repeat the process for the

second steering cable.

❏

18. Lower the nose gear retract and slide a metal furl on

each of the steering cables. Route the cables through the

attachment arms on the nose gear and back through the furls.

With the steering servo arm centered and the nose gear

straight, pull the cable tight. Then, crimp the two furls on the

cable. Cut off the excess cable.

❏

19. Install a foam wheel on the nose gear retract following

the manufacturer’s instructions. If the foam wheel rubs slightly

on the retract, lightly sand the foam with 320-grit sandpaper.

15