Great Planes Seawind .60-.91 ARF - GPMA1360 User Manual

Page 11

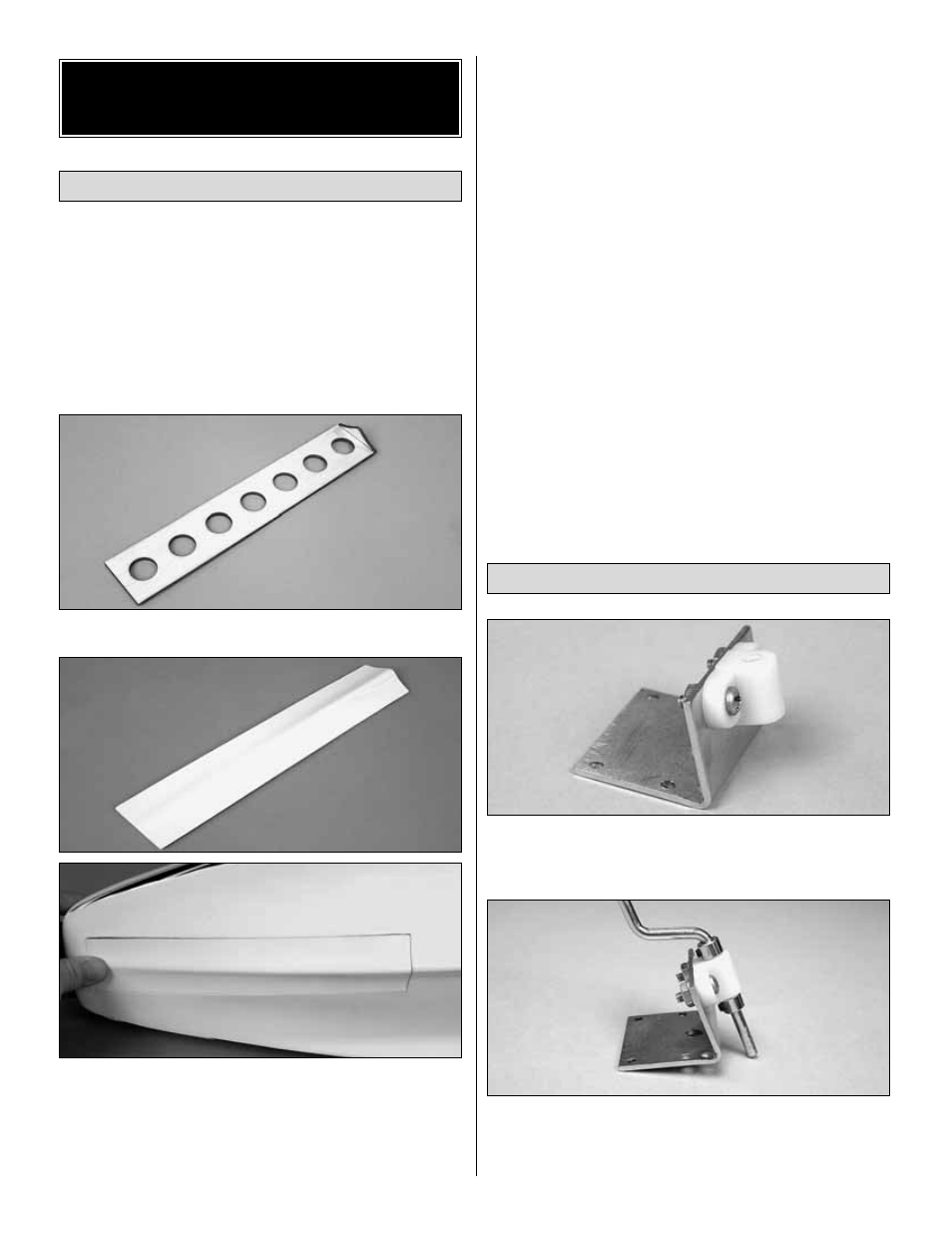

If the plane will be flown from water only, the nose gear cover

plate can be permanently glued in the fuselage. If you think

that in the future you may want to install landing gear in the

plane, follow the instructions below, but do not glue the nose

gear cover plate in the fuselage. Instead use clear box tape to

secure the plate in position.

If landing gear will be installed, proceed to

“Fixed Landing

Gear or Retractable Landing Gear.”

❏

1. Glue the plywood end plate to the nose gear cover plate.

❏

2. Use a canopy scissors or a Dremel

®

Rotary Tool and

sandpaper to trim the fiberglass nose gear cover to fit on the

nose gear cover plate and in the nose gear opening.

❏

3. Once the cover and cover plate fit well in the nose gear

opening, glue the fiberglass cover to the cover plate. Coat the

plywood plate with epoxy, thinned with denatured alcohol, to

prevent the wood from soaking up water.

❏

4. Use sandpaper to roughen the inside of the nose gear

opening where the cover plate will be glued. Clean the area

with denatured alcohol. Use epoxy to glue the nose gear

cover in the nose gear opening, flush with the bottom of the

fuselage. Note: Glue the cover on with silicone sealant if

you plan to remove it later.

❏

5. After the epoxy has cured, drill a 3/32" [2.4mm] hole at

the aft edge of the fiberglass cover plate to allow water to drain

out of the nose gear opening.

❏

1. Attach the nylon nose gear bearing to the nose gear

mounting plate using two 6-32 x 1/2" [4 x 12.7mm] machine

screws, two 6-32 [4mm] nuts and #6 washers.

❏

2. Slide a 5/32" [4mm] wheel collar on the nose gear wire.

Insert the nose gear in the nose gear bearing and install a

second 5/32" [4mm] wheel collar. Secure the wheel collars to

the nose gear wire with a 6-32 [4mm] set screw.

Fixed Landing Gear

Flying From Water Only

LANDING GEAR INSTALLATION

OR NOT

11