Great Planes PT-40 Kit (original) User Manual

Page 10

NOTE ON ENGINES: The engine mount

"breakaway plates" have been cut to an average width

which will permit mounting almost any engine you

choose. However, you may have to trim these plates

slightly to fit your engine. The best way to do this is

to sand or file away a little at a time from the inside

edges of both breakaway plates until your engine fits

between the plates.

NOTE ON FUEL TANK: The PT40 requires

any 6 or 8 oz. fuel tank of your choice. Most tanks

have three possible openings, one for fuel pick- up,

and two for the fill/vent lines. We recommend that

you only use two lines. Run one line from the "klunk"

pick-up to the fuel fitting on the engine carburetor

and the other to the "pressure tap" fitting on the

muffler.

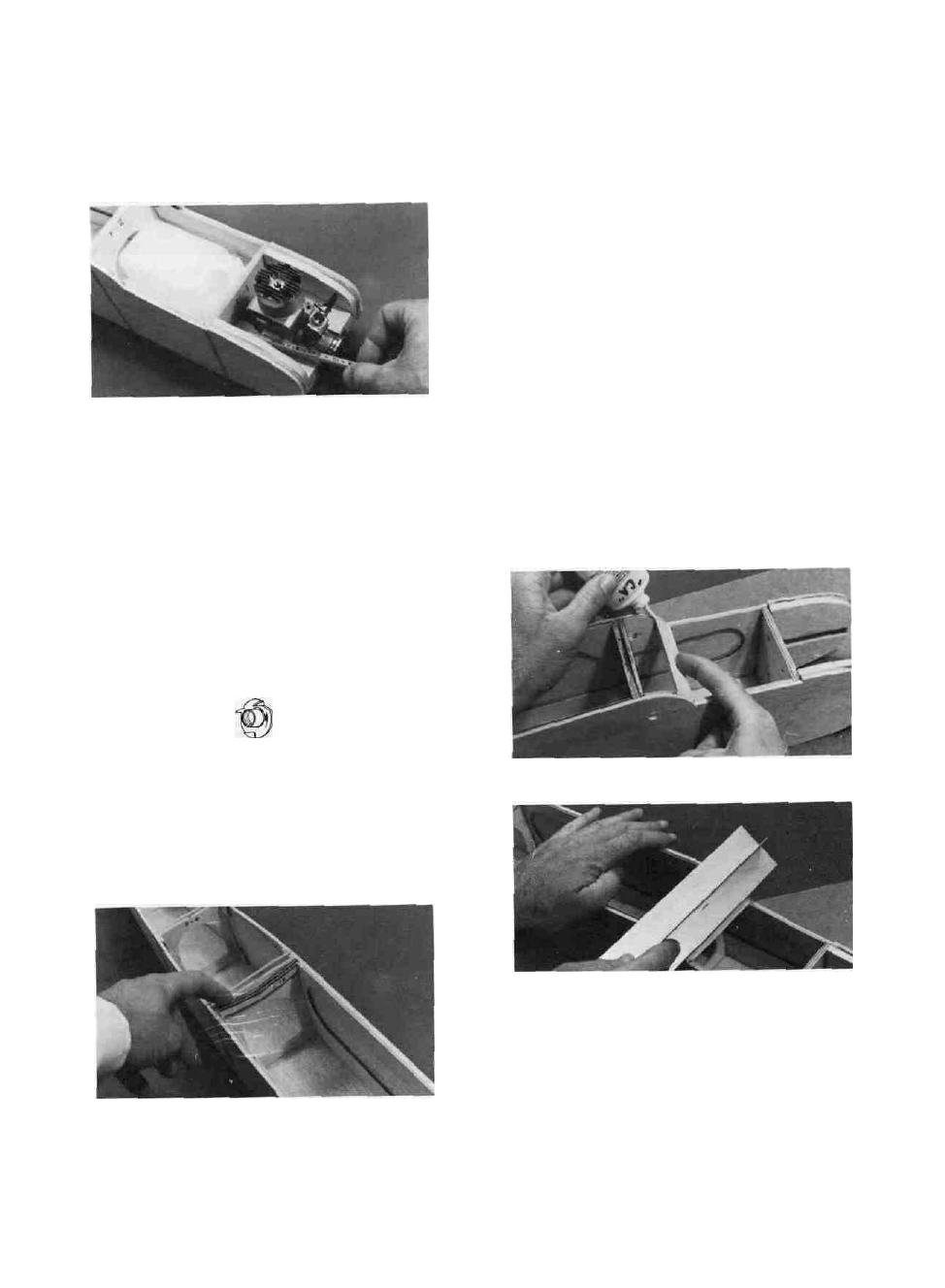

D 14. Because you have not yet glued the fuse parts

together, you may now carefully remove F-l and drill

the holes for the fuel lines and throttle pushrod.

D 15. Insert four 4-40 blind nuts part-way into the

1/8" holes previously drilled. Insert them from the

back side of F-l. Apply one drop of thick CA glue

under the wide part of each nut, then immediately

press them firmly in place with a pliers or a vise.

4-40 BLIND NUT

D 16. Replace F-l back into the fuse.

D 17. By now you should have decided which wing

you are going to build, "Wing A" (without ailerons),

or "Wing B" (with ailerons). If you have chosen'

"Wing A", find the four F-2A wing saddles and put

them into the slots behind F-2 and in front of F-3. If

you have chosen "Wing B", use the F-2B saddles.

D 18. Check your assembly of the fuselage, making

sure that all former tabs are in their respective

notches and all parts are in place. Set the fuselage

assembly on the plan top view. Your fuse assembly

should line up with the plan within 1/16". If not,

something is wrong and you should try to straighten

it out. If the alignment is far off and you can't find

the problem, consult with an experienced model buil-

der to correct the problem before proceeding.

D 19. Lay down a 50" long piece of waxed paper to

protect your building surface. Set the fuselage assem-

bly upright (in its normal position) on the waxed

paper. With everything in its proper place, apply thin

CA glue to all the joints, around the formers and

along the bottom. Wait a minute for the glue to set,

then apply thick CA to the joints to make sure a

good bond exists, especially in the joints that do not

fit perfectly. Note: The use of "Zip Kicker" or other

CA glue accelerator will be helpful when using thick

CA to fill any large gaps.

D 20. Remove the rubber bands from the fuselage.

In the above step you may have glued the rubber

bands to the wood in some places. If so, just cut the

rubber away from the wood with an X-Acto knife.

INSTALL THE WINDSHIELD

AND HATCH

D 1. Put the 1/2" balsa triangle windshield brace

in place and apply thin CA glue.

D 2. Sand the 1/2" balsa triangle to match the curve

on the fuse sides.

D 3. Sand the bottom edge of the l/8"balsa

windshield at an angle so it will rest flat on the fuse

sides.

D 4. Apply thick CA to the 1/2" balsa triangle, then

immediately place the windshield in position, hold-

ing the bottom against the triangle.

10 (See photo, top of next page.)