Great Planes Fun One 40 - GPMA0490 User Manual

Page 25

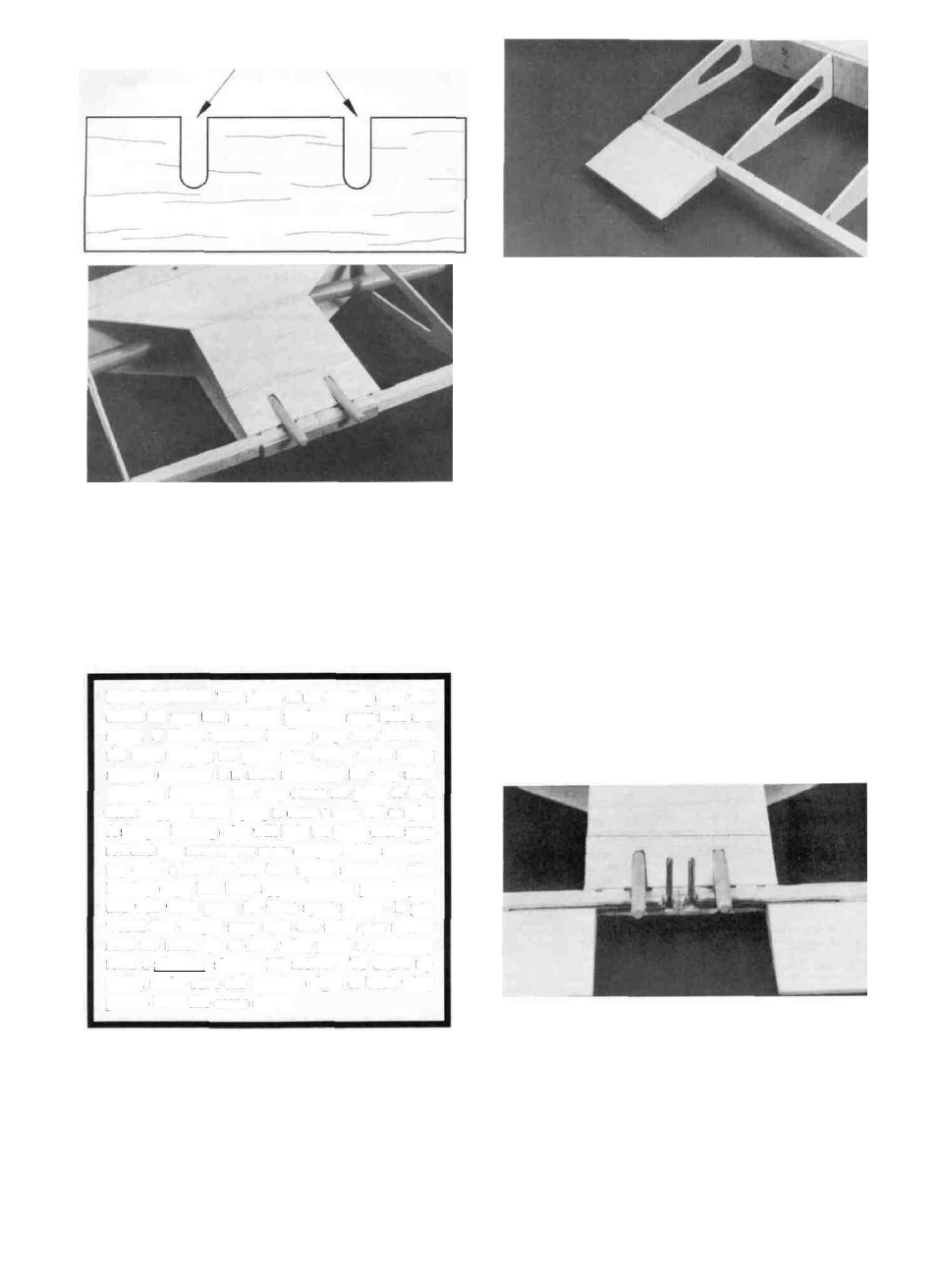

Cut out for dowels

D 3. Cut the front center sheet at an angle to match up

with the rear pieces as shown in the photo. Also cut away

the sheeting on the bottom of the wing for either the servo

cables or the aileron servo whichever the case may be.

that they follow the natural contour of the wing and are

not tilted up or down. Sand them to fair smoothly with

the TE and sand the ends flush with rib W10.

D 6. Tack glue the 1/8" plywood Wing Tips (FUN1W01)

in place with two drops of med. CA. They should line up

with the front portion of the airfoil and be centered with the

3" aileron portion at the TE. Sand the wing and wing tip

to get a smooth transition between the two. Remove the

wing tip and sand both sides smooth and lightly sand the

edges to remove any "fuzz". They will be glued back on

after the plane is covered.

D 4. Sand the leading edge so it will blend in smoothly

with the leading edge sheeting.

IMPORTANT: The shape of the leading edge will

affect the way this airplane performs snap rolls and

spins. A blunt, rounded leading edge will "soften"

the stall, making the plane very docile when flying

slowly, enabling it to flare nose-high for very slow

landings; however, this may cause the plane to be a

little sluggish when trying to enter a snap roll or spin.

A sharper leading edge will help the plane enter snap

roll and spin maneuvers more crisply, while sacrific-

ing only a little of the low speed stability. The

leading edge has been approximately pre-shaped,

and will work great for most sport flying. If you

would like crisper snap rolls and spins you should

sand the inner 1/3 of each wing panel to gradually

form a slightly sharper LE radius. To avoid tip

stalls, make sure the leading edges of both wing

panels have the same shape.

D 5. Cut 3" off each aileron (FUN 110) and glue the

short pieces to the tip end of each trailing edge. Make sure

INSTALL AILERON TORQUE RODS

(One aileron servo only)

D 1. Remove the dowel aligner which was tack glued

into place.

D 2. Cut a groove to fit the torque rods in the TE. A

clearance groove also has to be cut in the top of the TE to

allow the torque rods to move. Also cut small clearance

notches in the dowel aligner. Note: The torque rod

horns must exit the BOTTOM of the wing! Test fit the

torque rods in the groove, they should be totally in the TE

so the dowel aligner will fit back into place.

25