Garelick 71039 MOTOR BRACKET User Manual

Page 2

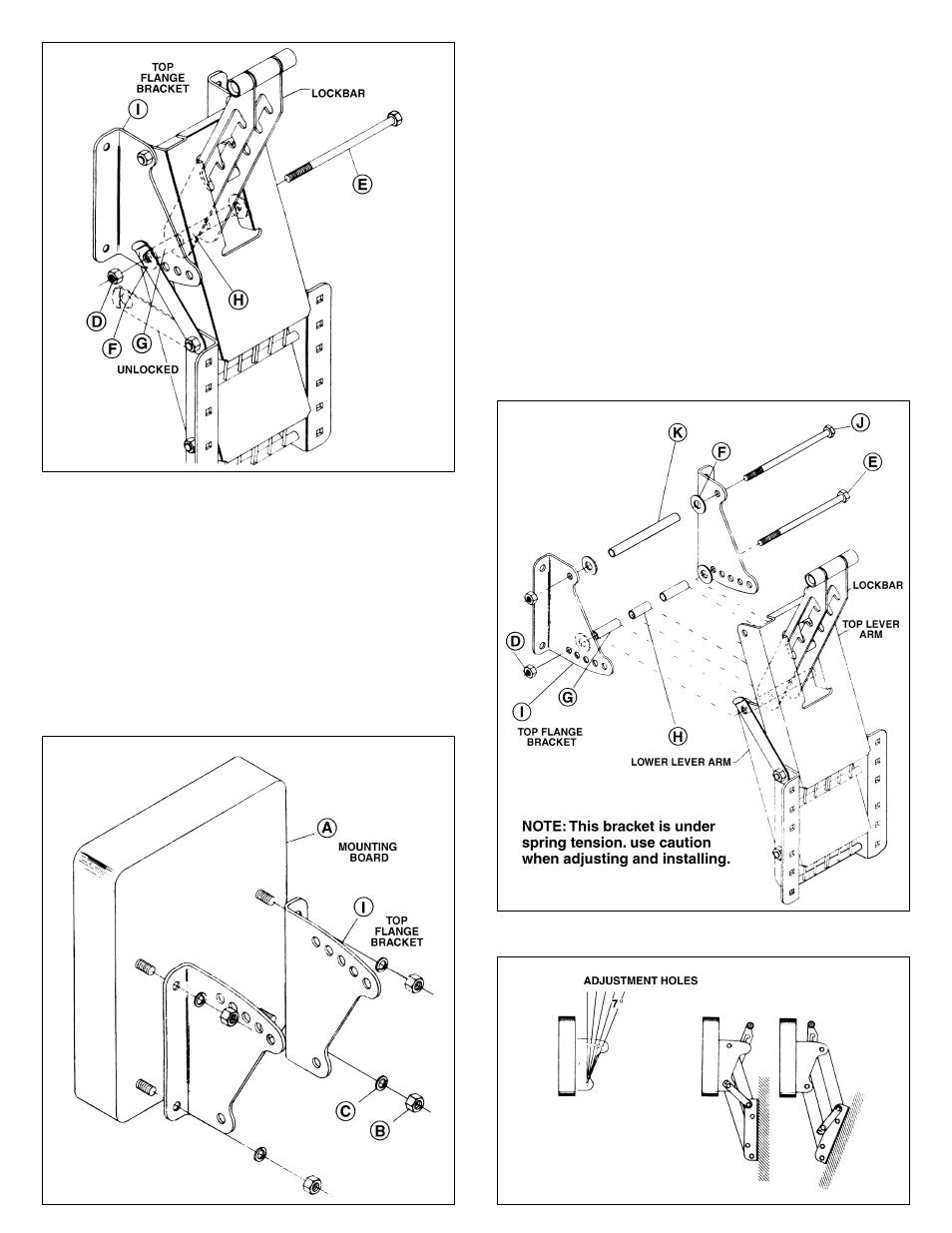

FOR POSITIVE ANGLED TRANSOMS

Refer to Figs. 5, 6 & 7

Begin the adjustment of your bracket by removing mounting

board (A). This is done by unscrewing four nuts (B) and

lockwashers (C). Pull safety lock out and rotate it to the

“unlocked” position. Unscrew locknut (D) and pull out pivot bolt

(E). Unscrew locknut (L) and pull out pivot bolt (J). Now flip the

top flange brackets over and put the left bracket on the right

side and the right on the left side as illustrated in Fig. 5 insert.

Reattach the flange brackets to the bracket by sliding pivot bolt

(E) through the lower hole in the flange bracket, (I), washer (F)

lower lever arm hole, spacer (G), lockbar arm hole, spacer (H),

lock bar arm hole, spacer (G) lower lever arm hole, washer (F)

and out the other lower hole in the flange bracket. Secure bolt

in position with nut (D); Do not overtighten nut so as to bind

operation of bracket. NOTE: Bolt must protrude through the top

of the nut to insure locking.

Use the measured angle of your transom to choose the proper

adjustment hole in your bracket that will best compensate for

this angle. NOTE: Each adjustment hole represents a 7°

increment (Refer to Fig. 7). Now, replace pivot bolt (J) through

the desired adjustment hole in the top flange bracket (I).

Reassemble unit by sliding bolt through washer (F), upper lever

arm hole, spacer (K), upper lever arm hole, washer (F) and out

other desired adjustment hole in top flange bracket. Secure bolt

in position with nut (L). Now replace the mounting board (A) as

pictured in Fig. 5 on your bracket with washers (C) and nuts (B).

Secure in position. Move safety lock back into “locked”

position. Refer to mounting instructions.

FIG. 4

FIG. 6

FIG. 7

FIG. 5