Garelick 71039 MOTOR BRACKET User Manual

Garelick Accessories for water

Mounting and Operating Instructions for

Outboard Motor Bracket

Models 71033, 71056, and 71039

Form 12.185

IMPORTANT INSTRUCTIONS

1. Read instructions completely before starting assembly.

2. Motor bracket must remain in “UP” position throughout

installation.

3. DO NOT operate motor bracket unless motor is installed

on bracket.

4. NOTE: This bracket is under spring tension. Exercise

extreme caution when adjusting and installing.

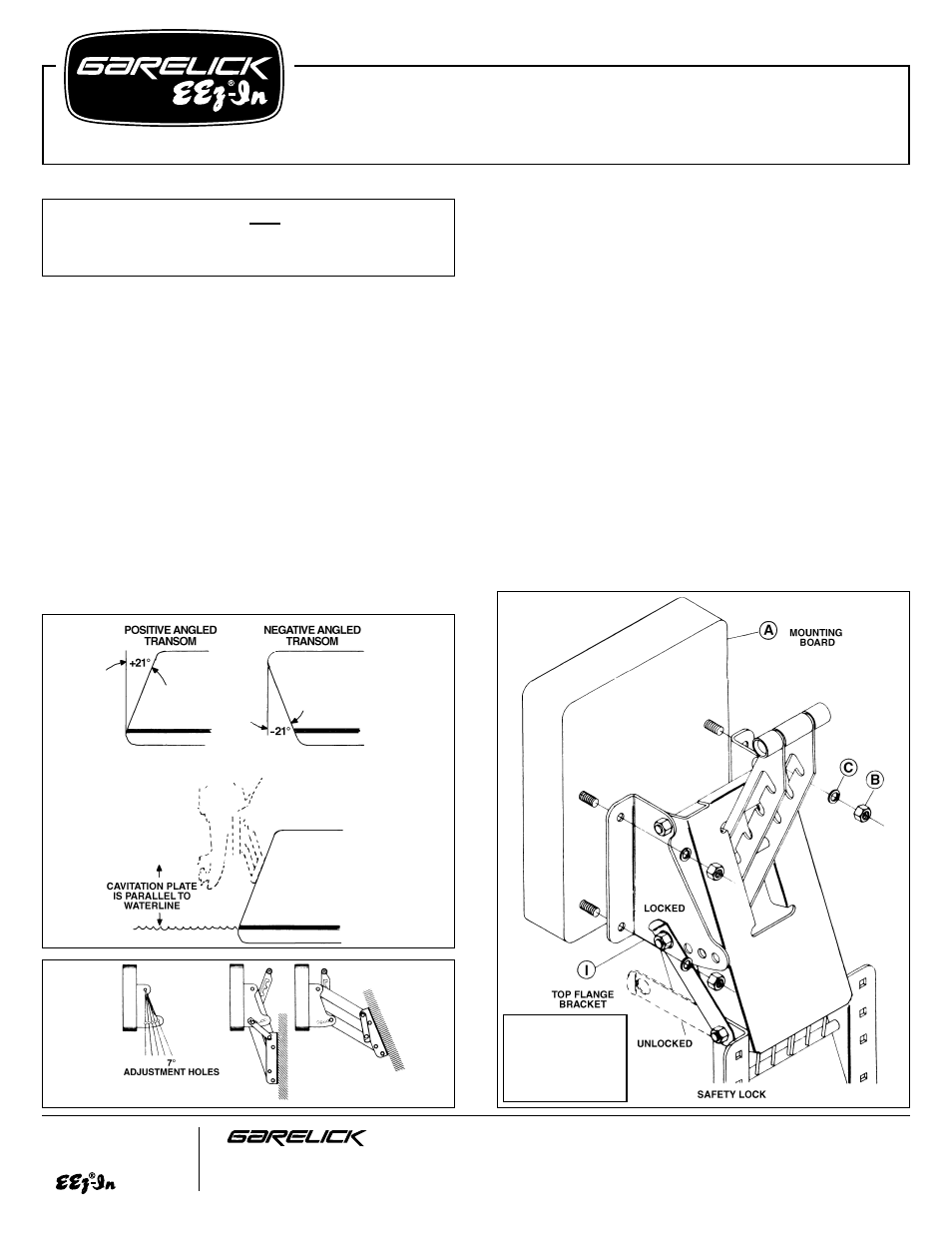

BRACKET ANGLE ADJUSTMENT INSTRUCTIONS

Refer to Fig. 1.

Measure the exact angle and direction of the transom on your

boat. Determine if your motor can be adjusted so the cavitation

plate is parallel to the waterline. If this is possible then skip the

following adjustment instructions (Figs. 2-7) and go to the

“Mounting Instructions” on Page 3. If your motor cannot be

trimmed properly, then follow the section below for the type of

transom you have: “POSITIVE” or “NEGATIVE.”

FIG. 1

FIG. 2

FIG. 3

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street

E-mail: [email protected]

St. Paul Park, Minnesota 55071

On the Web: www.garelick.com

10/08

FOR NEGATIVE ANGLED TRANSOMS

Refer to Fig. 2, 3 & 4

Now that the angle and direction of your transom have been

determined, choose the adjustment hole on your bracket that

will best compensate for the angle of your transom.

NOTE: Each adjustment hole represents a 7° increment.

Refer to Figs. 3 & 4

Adjust your bracket by removing mounting board (A). This is

done by unscrewing four nuts (B) and lockwashers (C). Pull

safety lock out and rotate it to the “unlocked” position. Unscrew

locknut (D) and pull out pivot bolt (E). Now replace pivot bolt

(E) through the desired adjustment hole in the top flange

bracket (I). Reassemble unit by sliding bolt through washer (F)

lower lever arm hole, spacer (G), lock bar arm hole spacer (H),

lock bar arm hole, spacer (G), lower lever arm hole, washer (F)

and out the other desired adjustment hole.

Secure bolt in position with nut (D); do not overtighten nut so as

to bind operation of bracket. NOTE: Bolt must protrude through

the top of the nut to insure locking. Pull safety lock out and

rotate it back into the “locked” position. Replace the mounting

board (A) on your bracket with washers (C) and nuts (B).

Secure in position. Refer to mounting instructions.

This bracket is

NOT for use

with 4-stroke

outboard motors.

NOTE: Vertical travel distance assumes a transom 90° to the water surface.

If the angle is greater than 90° we recommend

using a wedged shim to bring the

angle back to 90° to maintain

travel distance and proper

cavitation plate position for

best performance.

Transom Mounting Hardware NOT Supplied Due to Various

Transom Thicknesses.

Recommend 5/16" Stainless Steel Fasteners