Fleet Engineers INS-07034 User Manual

Page 2

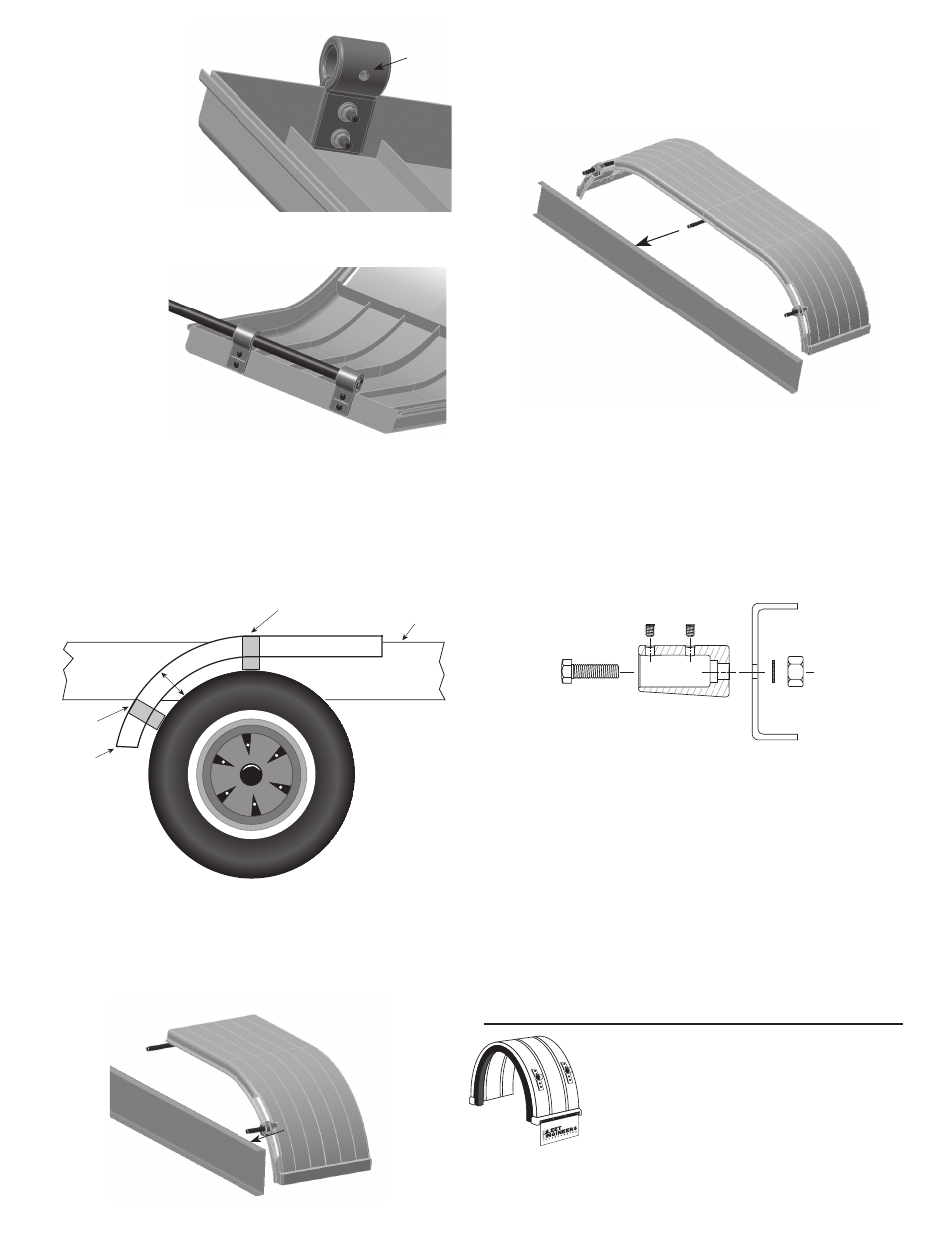

Spacer

Blocks

Spray

Master

Spacer

Blocks

Truck

Frame

3" Minimum

3" Minimum

4. Insert a T-nut into

each of the two

center mount con-

nector clamps from

inside the tube hole.

Select either a bent

tube or the Master

Multi-Mount straight

tube for the cen-

ter mount. (NOTE:

the bent tube uses

either a 1.37 or a 1.87” tube opening connector clamp while

the Master Multi-Mount center mount uses a 1.37” tube open-

ing connector clamp). Take the mounting tube selected and

slide through

both connectors

while holding

the T-nuts in

the connector

clamp in place. If

using the Multi-

Mount, assemble

castings to the

straight tube

using installation

sheet INS-03029

for position

purpose only.

5. Flip fender back over and position over tires. If installing a

Double Radius Fender, watch for “pinched” finger at center

connection. Use 2 x 4 blocks or other suitable spacers to

achieve desired clearance around tires. (S.A.E. recommenda-

tion is 3” minimum).

Note: If you have an air suspension, make sure there is tire

clearance when the suspension is deflated.

6. On the frame side of the fender, position the hidden END

mount clamp (with tube) as necessary to select an existing hole

or mark a space on the frame to drill a new hole. Make sure the

tube is square to the frame and mark the position of the hidden

end mount clamp on the fender.

6A. If installing a double radius fender, do step six to both ends of

fenders.

7. Adjust the center mount tube to select an existing hole if avail-

able, or mark a space on the frame to drill an new hole.

Note: Be sure to follow truck or trailer manufactureres recom-

mended procedures for drilling any required holes in the frame.

8. Remove fender from over tires and drill hole(s) if necessary.

Engage hidden mount teeth of clamp onto the hidden pocket

teeth of the fender and push firmly until they seat over top and

bottom ribs. A tap or two with a soft faced hammer may be

needed. Torque bolt at center rib support to 38 ft. lbs.

Note: If clamp removal or reposition is necessary, an outward

tap with a soft faced hammer will disengage it from the ribs.

9. Mount tube casting sleeve to the truck frame at the end mount

location. See installation sheet INS-03028.

Please Note:

Flap weights are not recommended and may

void the warranty.

Painting Spray Master fenders IS NOT recommended

and may void the warranty. If painting is desired,

use Valspar Plastic Enamel for best results.

10. Position the fender back on the vehicle and connect the END

and CENTER mounts to the vehicle. Check to make sure the

fender is centered over the tires. (In a few cases it may be

necessary to shorten the hidden mount end tube. If this is the

case, be sure to cut the non threaded insert end only!) Tighten

all bolts to proper torque. Install the set screws in both the

center connector clamps and hidden end mount clamps and

tighten to a maximum torque of 48 in. lbs. +/_ 3in. lbs. or 4

ft. lbs. Install end caps on center mount tube per installation

sheet INS-20014. Peal plastic off fender reflectors.

T-nut

Mark position

Mark position

on frame