Fleet Engineers INS-20011 User Manual

Installation instructions, Assembly instructions

Installation

Instructions

patent #6,604,724

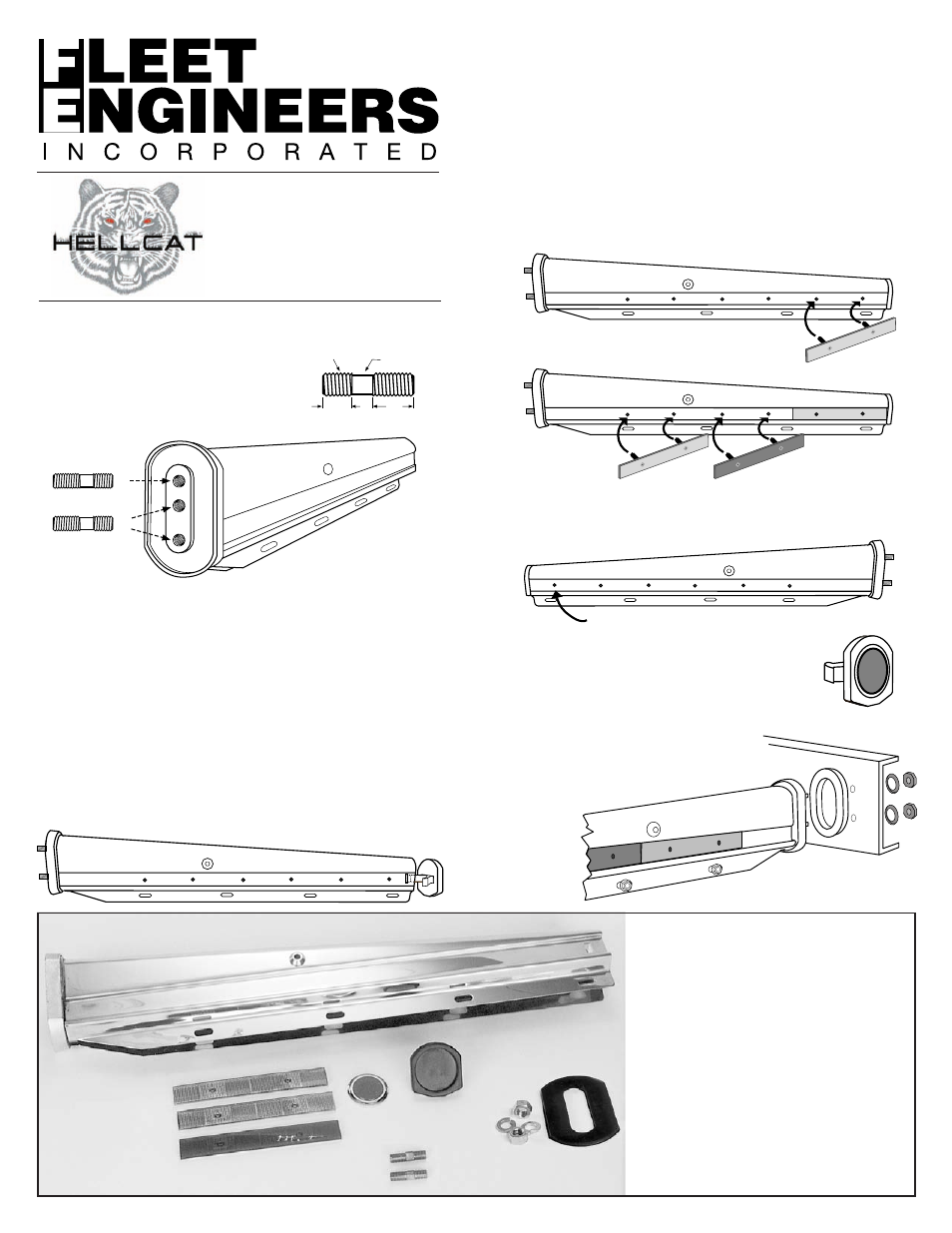

1. thread the

TAP END (short end)

of stud into tapped hole (a) of the

bracket frame seat all the way

to the flat section using a 3/8” or

adjustable wrench on the flat sec-

tion.

Assembly InstructIons

each HeLLCat Kit Includes

a) 2 tapered Brackets

B) 4 Mounting Studs

C) 2 anti-Vibration Gaskets

D) 2 Red Conspicuity Reflectors

e) 4 White Conspicuity Reflectors

F) 2 end Caps

G) 2 end cap Reflectors

H) 4 nuts & Lock Washers

12 nylon Snap Rivets (not shown)

12 plastic Hole plugs (not shown)

A) Tapered Bracket

B) Mounting Studs

C) Anti-Vibration

Gasket

D) Red Conspicuity

Reflector

E) White Conspicuity

Reflectors

F) End Cap

G) End Cap Reflector

H) Nuts & Lock

Washers

5.

When installing REFLECTORS, make sure the end cap and

bracket reflector recesses are clean, dry and free from any

oil or dirt. The use of a cleaning solution is recommended.

View bracket from the rear as it would be mounted on the truck and

start from the outside end. Insert two nylon snap rivets into the holes

of a white reflector. DO nOt push on the heads of the snap rivets

at this time. peel the protective strip from the adhesive backing.

Insert the rivets into the two mounting holes closest to the end of

the bracket. press the reflector in place. now push the heads of

the snap rivets firmly in. Repeat the process with the red reflector,

placing it next to the white one. Make sure to use the snap rivets

to align the reflector with the mounting holes. Do the same thing

with a white reflector, placing it next to the red one.

STUD

3/8"

Tap End

Nut End

Interference

Fit

Wrench Flat

Section

7/8"

A

B

C

A

B

C

OR

After removing protective backing from

white reflector, use rivets to find location

as shown. Press firmly in place.

Attach the red, then the next white reflector as described above.

Insert plastic hole plugs in 6 places.

6. On the opposite side of the bracket (facing tire), insert plas-

tic hole plugs into the six unused holes.

Note:

Thread locking

compound may be

used on tap end of stud

2. thread the

TAP END of the other stud in either tapped hole

(B) or (C) of the bracket frame seat all the way to the flat sec-

tion using a 3/8” or adjustable wrench on the flat section. Use

hole (B) for 1-1/8” stud/hole centers. Use hole (C) for 2-1/2

stud/hole centers.

Note: If frame thickness exceeds .50 in., the studs should be

replaced with grade 5 or better studs or bolts of appropriate

length. Make sure there is a minimum of .63 thread engage-

ment in the frame seat.

3. assemble mud flap to bracket.

4. Insert the

END CAP into the bracket one leg at a time with a

rocking motion. Make sure the clips on the cap engage the

slots in the bracket.

Installa

tion Sheet #I

NS

-2

00

11

•

6

/0

0 • Rev

. B 11/02 • Rev

. C 12/06

Installation Sheet #InS-20011

7. to install round reflector on end cap, peel

protective backing and press firmly in place.

8. place antivibration gasket in recess on frame seat of

bracket. Fasten bracket to truck

with 1/2” lock washers and nuts

torqued to 57 ft. lbs.

9. Repeat process

for the

other

bracket.

®