Fleet Engineers INS-07034 User Manual

Spray master

Spray Master

®

Half Tandem

& Double Radius Fender

Installation Instructions

Installation Sheet #INS-07034

Patent Pending

NOTE: These instructions for installing Spray Master fenders are in-

tended to be a general guide to help the installer. Because of the large

number of possible mounting

configurations, the installer is

responsible for the installa-

tion design and for providing

adequate clearance around

the tire carrier (i.e. tire clear-

ance, trailer clearance, etc.)

This product may not fit all

truck models or types of

suspensions. Check truck

or trailer manufacturer for

suspension travel specifications. Modifications to the brackets and/or

the fenders may be required. Any modifications are at the discretion,

responsibility and risk of the installer and may void warranty.

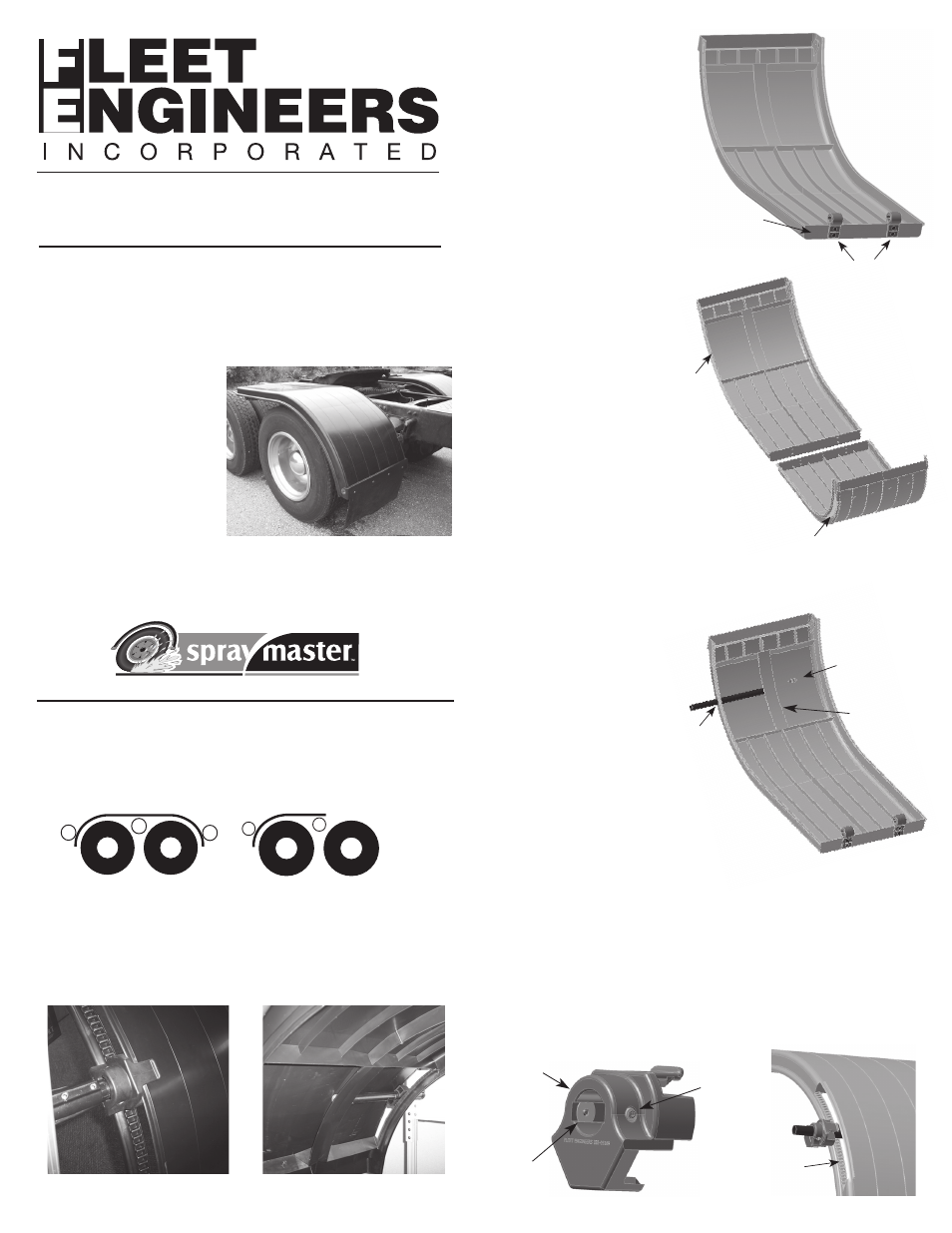

1. Position the fender up-

side down, making sure

to protect the top side

from getting stratched,

etc. Take two center con-

nector clamps and, with

the square holes facing

outward, slide over the

fender center cap. Align

with the holes in the fender

and secure with 2” bolts

and lock nuts. Torque

to 16 ft. lbs.

Installation Sheet # INS-07034 • Rev. B 2/13

3. Insert two T-nuts into each hidden end mount clamp from

inside clamp tube hole. Hold T-nuts in place while sliding over

the mounting tube. Do not slide hidden end mount clamp over

ribs on fender.

3A. If installing a double radius fender, do step three to both

fenders.

The figures below show the general locations of mounts on half

tandem and double radius tandem fenders (E = end mount / C =

center mount).

Double Radius

Tandem Fender

Half

Tandem Fender

Note: The Spray Master® half tandem fender is not universal;

there is a left hand fender (roadside) and right hand fender (curb-

side). The “hidden pocket” opening is always positioned towards

the vehicle frame.

1A. For Double Radius Fender

Only (if mounting half

tandem, go to step two).

To make a Spray

Master Double

Radius Fender,

two Half Tandem

fenders sets are

required. Take both

a roadside and a curbide

tandem fender and position

them upside down, making sure

to protect the top side from get-

ting stratched, etc. Both hidden

pockets must face the same way

- if not, you have either two road-

side or two curbside fenders. Align

the holes of the center caps of each

fender together and slide the two

center connector clamps into position over the two sets of

holes on the fender center cap surface. Secure the connec-

tor clamps with 2” bolts and lock nuts.

Torque to 16 ft. lbs.

2. Slide a hidden mount tube

with the threaded insert end

first, through the hidden

pocket opening

over to the center

rib support.

Attach to the

center rib support with a 1.5”

bolt and washer but do not

engage thread locking compound

yet, just start bolt up for positioning

purposes.

2A. If installing a double radius fender, do

step two to both fenders.

Left hand (roadside) shown

Center Cap

Connector

Clamps

Hidden

Hidden

Hidden

Bolt &

Washer

T-Nut

Fender Ribs

C

E

E

C

E

Center Rib

Support

T-Nut

Clamp

Tube Hole