Caution, Important – Fleet Engineers INS-97005 User Manual

Page 2

CAUTION!

The vertical track assembly may be raised a maximum of 1/2”

off the sill. Keep both vertical tracks the same length and same

distance off sill.

Mount the vertical track mounting angle flush with the inside edge

of the rear corner posts all the way up and down,

Figure 3.

It is critical that the vertical track is installed square. Check the

opening measurements at several points between the vertical

tracks, then measure diagonally. If your measurements are equal,

the door track is square.

The vertical track is to be welded through the plug weld holes to

the post on 12” to 15” centerline. The upper brackets (counterbal-

ance) must be properly secured, welded or bolted, to the header,

Figure 5.

STEP 6: Horizontal Track Installation -

It is important to maintain the same distance between the hori-

zontal and vertical tracks. If wider than the vertical tracks, shim

horizontal track accordingly.

Fasten horizontal tracks securely to provide adequate support for

the door and weld the full length of the couplers at the track joints.

CAUTION!

STEP 7: Counterbalance Installation

If door is equipped with a pre-wound counterbalance, special

precautions must be exercised when handling this assembly. The

spring on this type counterbalance is factory pre-wound and is

under tension.

DO NOT loosen any of the spring set screws until final installation

of the pre-wound counterbalance detailed in Step 9.

Remove the bearing assembly from the road side vertical track.

Slide this bearing onto the right hand cable drum end of the coun-

terbalance shaft. Insert the left end of the counterbalance shaft

into the bearing assembly of the curb side vertical track. Remount

bearing to road side vertical track assembly.

Position and align the spring anchor bracket on the inside of the

header; be sure the shaft is not rubbing on the spring anchor cast-

ing. Allow a minimum of 5” for spring growth,

Figure 5. FIRMLY

SECURE SPRING ANCHOR BRACKET TO WITHSTAND THE

STRONG TORQUE OF THE SPRING.

An additional counterbalance support bracket is required on 102”

wide units.

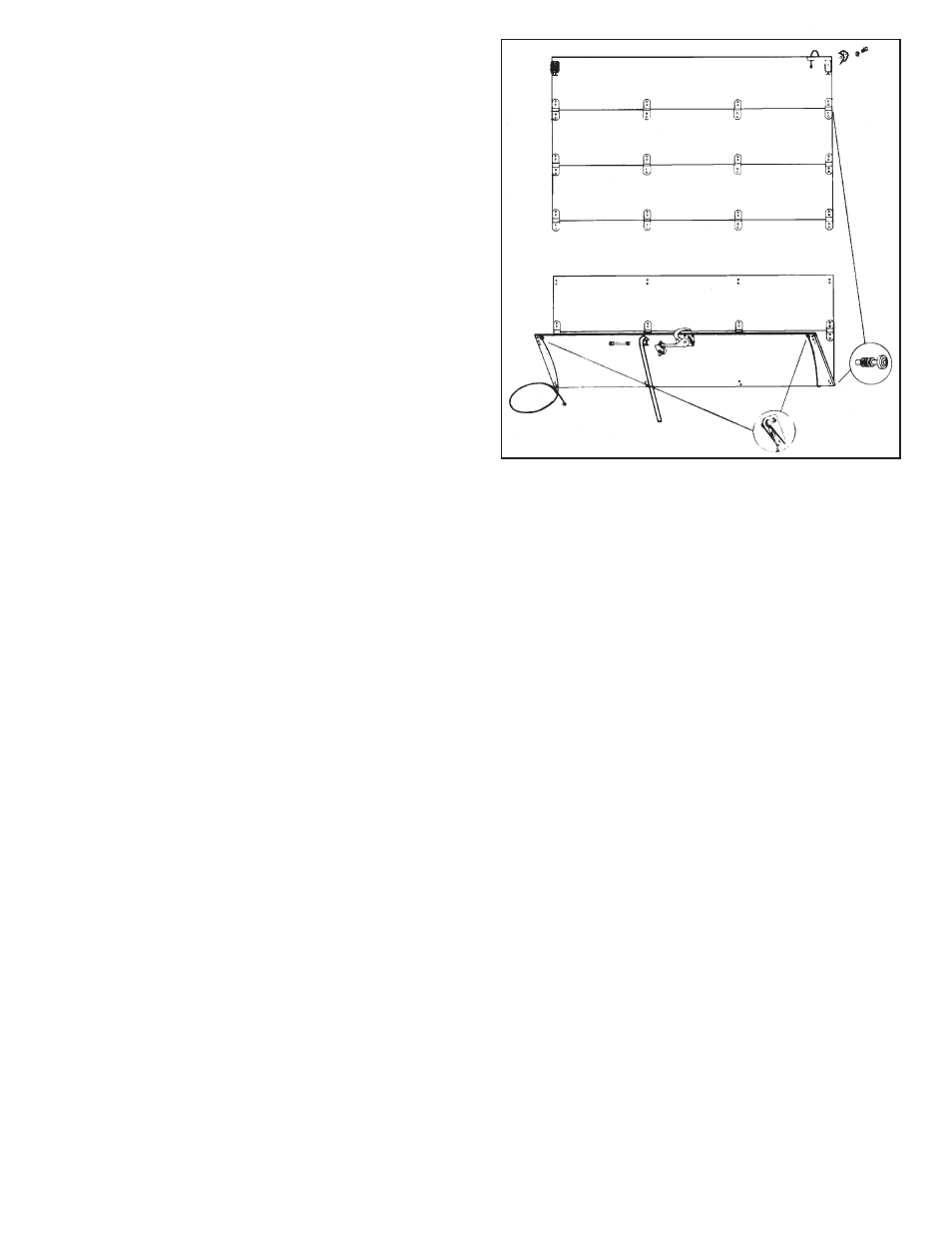

STEP 8: Door Installation

Assemble the door half sections together with the bolts, rivets

and/or hinge pins provided,

Figure 4. Attach cable assembly to

cable anchor bracket, secure with anchor & cotter pin.

Assemble the slide part of the adjustable top fixture to the pre-

mounted base with washer and bolt. Next, insert the roller shafts

into the end hinges, top and bottom fixtures.

IMPORTANT!

ONE TO FOUR SPACER WASHERS SHOULD BE PLACED ON

THE LEFT AND RIGHT SIDES OF THE FIRST SECTION JOINT UP

FROM THE BOTTOM, AND THE FIRST SECTION JOINT DOWN

FROM THE TOP OF THE DOOR. THESE WASHERS WILL HELP

HOLD THE DOOR SQUARE WITH THE TRACK.

Before rolling the door into the tracks, bring the cable ends to the

top of the door and tape to the inside of top panel,

Figure 4.

If the unit has no other door, place two small blocks of the same

size under each corner of the door so a light may be placed in the

unit. The blocks will keep the door even while you wind the cables

and counterbalance spring.

Insert door and carefully lower door, supporting door weight onto

wood blocks on sill. Install track stop bolt in end of horizontal

track.

With the door closed, bring the road side cable up between the

drum and the header.

Hook the cable end in the slot in the outer groove of the right

cable drum. Starting in first groove, wind the cable on the drum

winding drum towards you, make sure it properly tracks in each

groove of the cable drum.

Take up the cable slack until snug; push the drum against the

bearing and properly tighten both set screws. Now, clamp the

counterbalance shaft with vice grips, (handle of grips against the

ceiling) to hold the cable taut.

(Figure 5)

Repeat the procedure with the curb side cable and drum.

IMPORTANT!

1. CABLE DRUMS MUST BE TIGHT AGAINST BEARINGS.

2. CABLE IS PROPERLY TRACKING IN CABLE DRUM GROOVES.

3. CABLES MUST HAVE EQUAL TENSION.

4. SET SCREWS MUST BE TIGHT.

STEP 9: Spring Winding

To determine the amount of winds on the counterbalance spring,

divide 10 into the door opening height in inches and add 3 turns.

Example: 75 divided by 10 = 7.5 turns + 3 turns = 10.5 or 10 and

one-half turns

Run a chalk mark,

(Figure 5) the full length of the counterbalance

spring. Leave the vice grip clamped to the shaft to keep tension

on the cables.

Place a 1/2” dia. x 18 winding bar in the hole in the spring wind-

ing plug. Wind the spring by lifting up the bar. While holding the

first bar, place a second bar in the next hole and lift in the same

manner after removing the first bar. Repeat this until the correct

number of complete turns are obtained by counting the chalk

marks which show up as stripes as the spring is wound.

Properly tighten both set screws on the spring winding plug and

remove the vice grips from the counterbalance shaft.

IMPORTANT!

USE 1/2” DIA. x 18” WINDING BARS ONLY. DO NOT USE

SCREWDRIVERS OR TAPERED PUNCHES FOR WINDING.

A properly counterbalanced door should, when stopped, remain at

any given location. If the door leaves the floor by itself, the spring

is wound too tight and a few quarter-turns should be released.

If the door has any tendency to drop when stopped, a few more

quarter-turns should be added.

Figure 4