Assembly instructions – ebm-papst VDC-3-49.15 User Manual

Page 12

VDC-3-49.15

Assembly instructions

Article No.: 194 0005 008 · Version: V1.0 · dated 08.11.2011 · Page 12 of 14

ebm-papst St. Georgen GmbH & Co. KG · Hermann-Papst-Straße 1 · 78112 St. Georgen · Phone: +49 7724 81-0 · Fax: +49 7724 81-1309 · www.ebmpapst.com · [email protected]

Ori

g

inal installation

7 MAINTENANCE, MALFUNCTIONS, POSSIBLE CAUSES AND REMEDIES

⇒ Do not perform any repairs on your drive system.

⇒ Return the drive system to ebm-papst for repair or exchange.

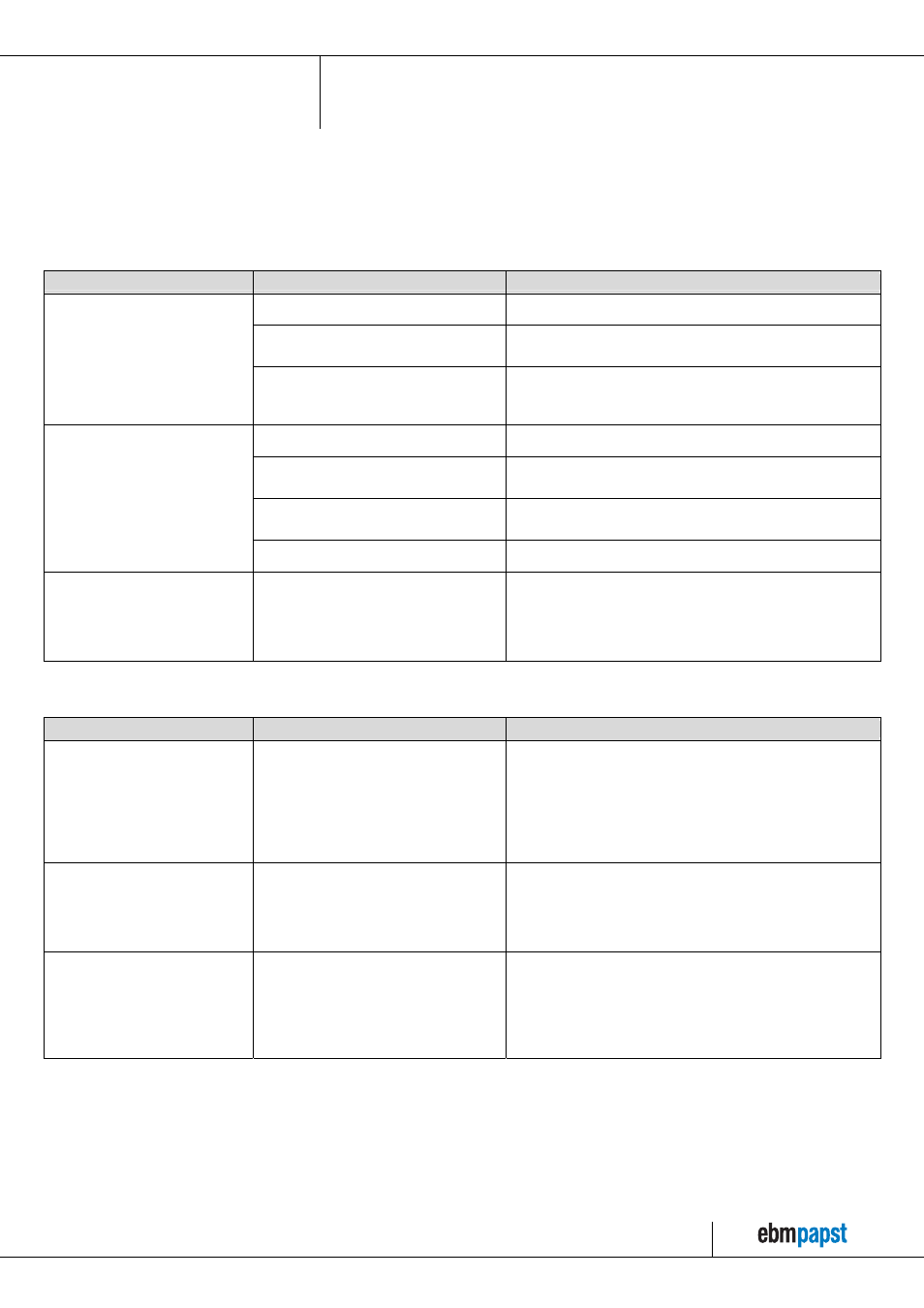

7.1 Troubleshooting

When switching on

Malfunction / error

Possible cause

Possible remedy

Motor does not start, the power

supply is switched on and within the

specified range

Missing set value signals at inputs S1 and S2

Specify desired set value

Missing digital signal at one of the inputs

(A / B)

Connect at least one of the two inputs for the desired operating

mode/direction of rotation

Missing signal level change (change from

0 to 1) at input "C" to set the motor to ready

state.

Switch on signal level at Input C again (change from 0 to 1)

The motor does not turn, the power

supply and control signals are

connected.

Load/required start-up torque are too high.

Reduce load or check motor dimensioning.

Mechanical blockage

Switch off drive, remove mechanical blockage in the powertrain and

attempt to restart

Faulty connection

Check that pin configuration and control signals are correct, see

Chapter 4 and Chapter 6

Drive defective

Replace drive

Motor accelerates briefly, then

switches off and runs down, fault

signal "D" is set.

High load or high acceleration with power

supply that is not designed to bear this.

Power supply reaches performance limit,

voltage drops sharply and drive detects

undervoltage.

If possible, reduce load or acceleration.

In the other case, check the dimensioning of the power supply and

use a more powerful power supply.

In operation

Malfunction / error

Possible cause

Possible remedy

Motor makes "clacking noises" when

braking function is activated or there

is a negative set value jump

Braking function:

Motor goes into brake operation, the fed-

back energy causes a voltage increase in the

intermediate circuit; when the max. reverse

voltage is reached, controlled brake

operation begins in order to protect the

system (refer to Chapter 5.8).

Use set value ramps instead of set value jumps. If a fast brake

reaction is needed, the fed-back energy can be removed more

quickly via an additional brake chopper in the intermediate circuit.

When operated for longer periods,

the motor torque output declines

Thermal overload: Motor is operated too long

at high load/at elevated ambient

temperature. Motor heating causes lowering

of the winding current by the I

2

t peak current

limitation

Check load point, ambient conditions and possibilities for heat

dissipation.

Reduce load, lower ambient temperature or provide better heat

dissipation.

When operated for longer periods,

the motor stops turning

Thermal overload: Motor is operated too long

at high load/at elevated ambient

temperature. Motor heating finally causes a

shutoff via the integrated temperature

monitoring.

Check load point, ambient conditions and possibilities for heat

dissipation.

Reduce load, lower ambient temperature or provide better heat

dissipation.

The drive cannot be switched on again until the NTC temperature

falls back to <100 °C.