Wing assembly – Carl Goldberg GBGA1041 User Manual

Page 4

4

2.

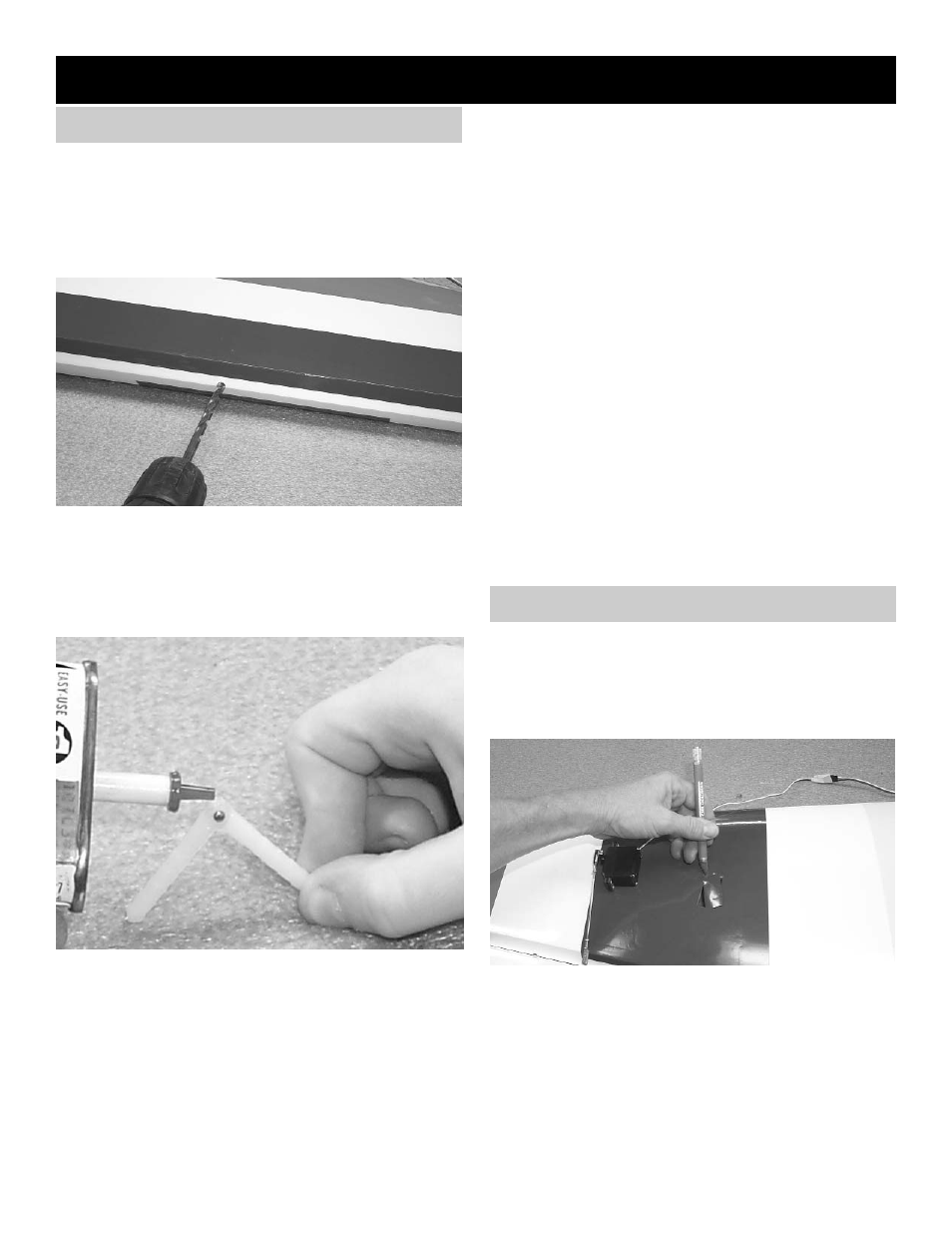

Locate the pre-drilled aileron hinge holes in both

wing halves. Using a 1/4” drill, drill each hole

1/8” deep. This will allow the center of the hinge

to be inserted half way into each of the surfaces.

Repeat this process with the ailerons, making

sure all hinges insert half way.

3.

Place 1 drop of oil on each of the hinges at the

center. This is to keep the hinges loose and

prevent epoxy from sticking at the joint.

Caution: Do not get any oil on the length of the

hinge or it will not glue into the surface.

WING ASSEMBLY

AILERON INSTALLATION

1.

Collect the following parts:

(1) Left wing

(1) Right wing

(1) Left aileron

(1) Right aileron

(10) hinges

4.

Select the aileron for the wing half on which

you are working.

Mix up a liberal amount of 30 minute epoxy.

Working with 1 hinge at a time, place a dab of

epoxy and insert the hinge half way into one of

the aileron holes.

Repeat for each of the other hinges for that

aileron.

5.

Working quickly, place some epoxy on the

second half of each hinge and insert the

aileron into the wing.

Slide the aileron toward the wing until no gap

remains between the aileron and the wing.

When satisfied with the alignment, flex the

aileron up and down to confirm that the hinges

are working freely. remove any excess epoxy.

Apply a few strips of masking tape to keep the

pieces in place.

Allow to dry before flexing the aileron.

6.

Repeat the above steps for the other half of

the wing.

AILERON SERVO INSTALLATION

1.

Collect the following parts:

(1) Left wing

(1) Right wing

(4) Servos

(2) 24” “Y” Harness

2.

Locate the two servo holes in the bottom of

wing.

Carefully cut the covering over the servo

holes.