BASO BGC258 Series BASOTROL User Manual

Page 2

2 BGC258 Series CE Approved Gas Valve Installation Instructions

6.

If you desire to measure the outlet pressure, use

the bottom cast pressure test fitting or use the

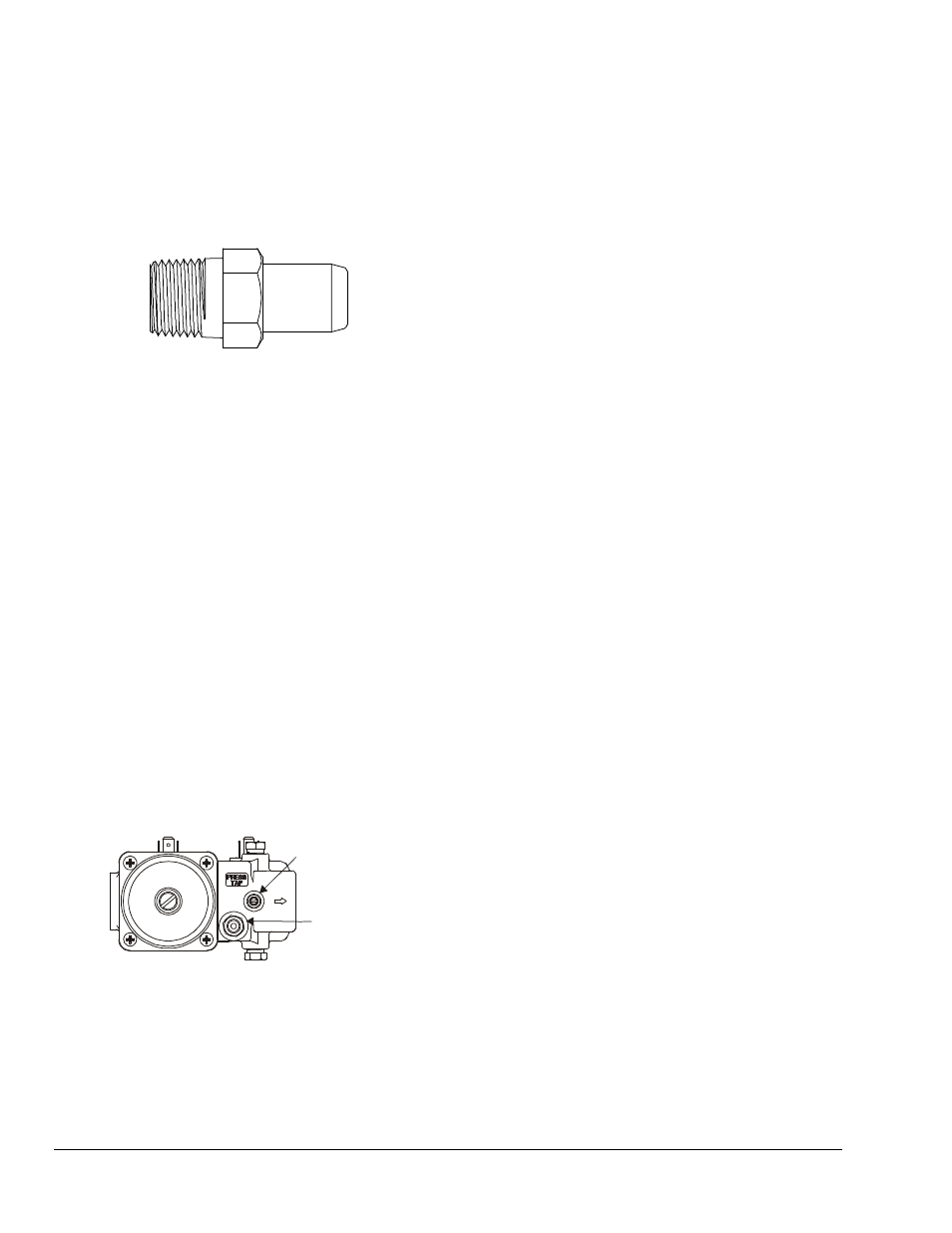

Y99AX pressure test fitting (see

Figure 2

) and an

approved pip joint compound on the male threads

and screw the fitting into dither side of the valve,

which ever side is convenient, replacing the

pressure tap plug.

Figure 2: Y99AX-1 (1/8-27 NPT) Pressure Test Fitting

Y99AX -2 (1/8-28 BSPT) Pressure Test Fitting

7.

Install the valve on the manifold; ensure the gas

flows through the valve body in the direction

indicated by the arrow on the body. If the valve is

installed with the gas flow in the opposite direction

of the arrow, leakage can occur.

Note: If installing a valve with threaded

connections, use an approved pipe joint

sealing compound on the male threads

before assembly. An optional thread

lubricant may have been factory applied to

the first two or three threads of the inlet and

outlet to avoid galling. Make sure that

excess compound is removed after

mounting. Threads of pipe and nipples

must be smooth and free of tears and

burrs. Steam clean all piping to remove

foreign substances such as cutting oil or

thread chips.

8.

Connect the pilot tubing (when necessary) to the

threaded pilot connection on the underside of the

valve body (Figure 3) and run the tube to the pilot

burner within the appliance. Connect the pilot tube

to the valve with an optional compression fitting.

Outlet Pressure

Tap Connection

Pilot Tube

Connection

Figure 3: Underside of Valve with

Direct-Acting Regulator

9.

Check for leakage before making any valve

adjustments.

a. Shut off the gas at the main manual shutoff

valve and open the pressure connection

between the manual shutoff valve and the

BGC258 valve.

b. Connect air tubing with a maximum pressure of

1-1/2 times the valve’s maximum operating

pressure (as indicated on the valve) to the

opened pressure connection.

c. Paint all valve body connections with a rich

soap and water solution.

If bubbles occur, this is an indication of a leak.

To stop a leak, tighten joints and connections.

Replace the part if the leak cannot be stopped.

If bubbles do not occur, remove the air tubing

and close the pressure connection.

10. Make wiring connections. See the Wiring section

for specific wiring instructions.

11. To measure the outlet pressure, apply power to

the valve and energizing both valve solenoids.

Use the outlet pressure tap connection on the

underside of the valve body to monitor the outlet

pressure. The outlet pressure tap is a bleed hole

with a cast spigot, sealed with a threaded brass

needle screw (Figure 3). To measure the outlet

pressure, turn the screw in a counterclockwise

direction one or two turns and fit a 9 mm diameter

flexible tube over the cast spigot. After all valve

adjustments have been made and the desired

outlet pressure has been obtained, remove the

flexible tube. Tighten the needle screw by turning

it clockwise with a slotted screwdriver until hand

tight, sealing the bleed hole.