BASO BG1600M51EF-1AA User Manual

Page 10

10 BG1600M51EF-1AA Universal Intermittent Pilot Ignition Control Installation Instructions

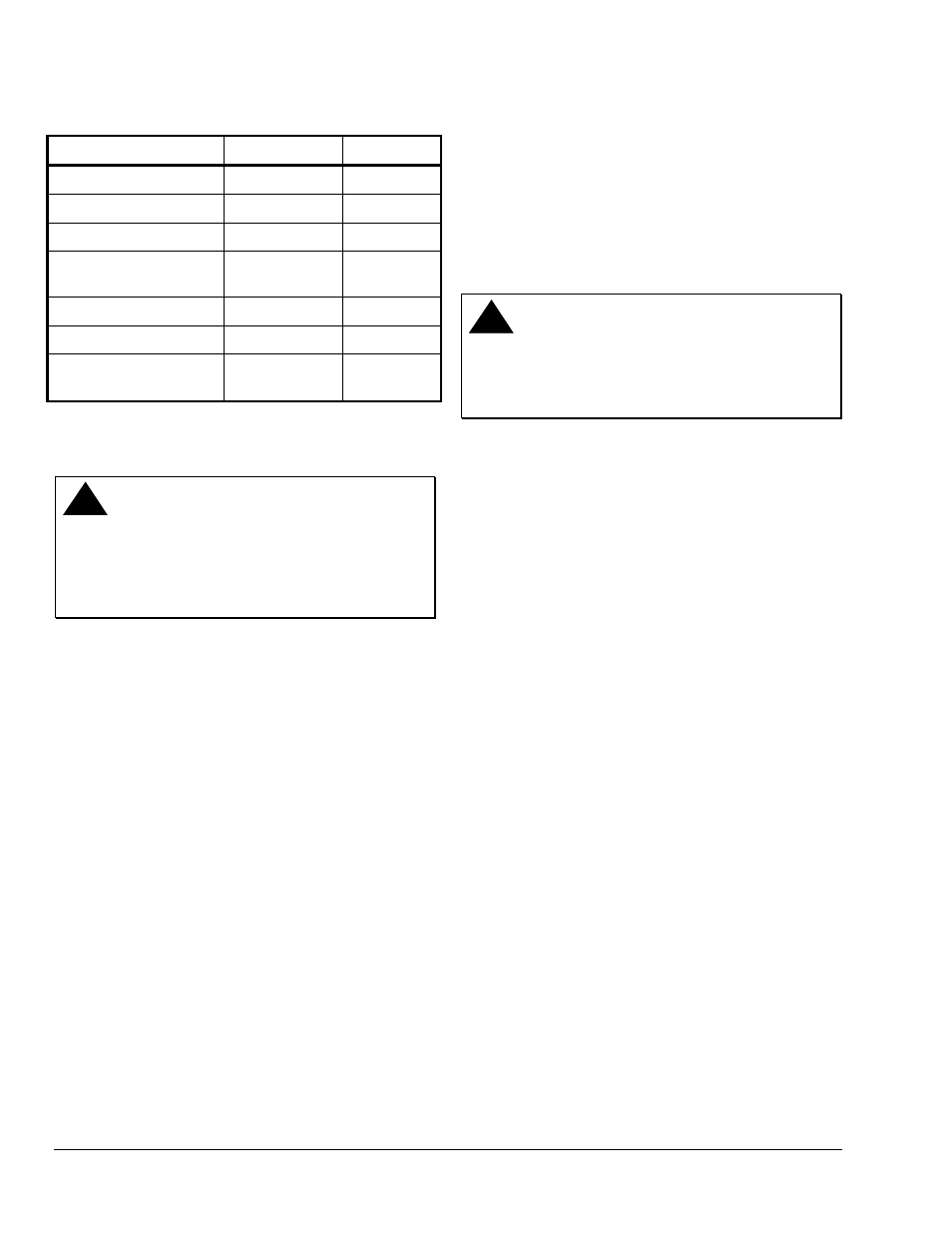

Table 3: Replacing Robertshaw® 780-845

Wire Function

780-845

BG1600M

Main Valve

MV

1 MV

Valve Common

PV-MV

2 MV/PV

Pilot Valve

PV

3 PV

Pilot Burner Ground

GND

4 GND

(BURNER)

Power Supply Ground

TR

5 GND

Thermostat

TH

7 TH

Sense Electrode

(if two rod sense)

SENSE

8 SENSE

Note: Verify that the spark wire is noise suppression

(resistive) type and replace if necessary.

Checkout

!

WARNING: Risk of Explosion or Fire.

Verify that there are no gas leaks by testing with

appropriate equipment. Never use a match or lighter

to test for the presence of gas. Failure to test

properly can lead to an explosion or fire and may

result in severe personal injury or death.

Make sure all components function properly by

performing the following test.

1.

Before starting the appliance, perform a safety

inspection of piping, burners and venting. Check

for water leaks, etc. Check all wiring for proper

connections. Be sure the system is properly

grounded, including ground connection to the

pilot burner.

2.

With the gas and thermostat off, turn on power to

the appliance.

3.

Turn the thermostat to a high setting and verify

that the control goes through the operating

sequence to a shutoff condition.

Note: The burner does not light because the

gas is off.

4.

Turn off the thermostat.

5.

Turn on the gas and purge gas lines of all air.

6.

Check for gas leaks on all pipe joints upstream of

the gas valve with a soap solution.

7.

Turn the thermostat to the highest setting and

verify successful ignition and a normal run

condition for at least 5 minutes. If the appliance

fails to run, see the Troubleshooting section.

8.

Check for gas leaks on all pipe joints downstream

of the gas valve with a soap solution.

9.

Turn the thermostat down for at least 30 seconds

and then back up again. Verify successful ignition

at least five times.

10. Return the thermostat to a normal temperature

setting before leaving the installation.

!

WARNING:

The control module can not be serviced by user. If

any faults are detected, the control module must be

replaced. If control module has been opened or any

attempts to repair are done, the warranty is void.

Operation

Operating Mode Definitions

The following definitions describe the

BG1600M51EF-1AA operating conditions.

• Prepurge: Initial time delay between thermostat

contact closure and activation of the spark circuit

and pilot valve.

• Trial for Ignition: Total time the pilot valve is

energized and spark/sense sequence is activated

in an attempt to light the pilot. The control attempts

to prove flame within the trial-for-ignition time.

• 100% Shutoff: If the control does not prove the

presence of pilot burner flame within the trial for

ignition, the spark circuit and pilot valve are

de-energized.

• Recycle: If 100% shutoff occurs, the control

delays 5 minutes (recycle delay period) and

begins another trial for ignition.

• Run: Main valve is energized and spark turns off

after pilot flame is proven. The main valve remains

energized until the thermostat is satisfied.

• Flameout: Loss of proven flame. Should a

flameout occur, the main valve de-energizes and

spark recurs within 2.0 seconds.

• Lockout: An internal or external fault has caused

the control to de-energize the spark circuit and

valve relays. The thermostat contacts must be

opened for 30 seconds and then closed to begin

another trial for ignition.

• Inter-Purge: Period between trials for ignition

when both the gas valve and spark are

de-activated to allow unburned gas to escape

before the next trial.