AERCO Electronic Control Valve User Manual

Page 23

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

7-3

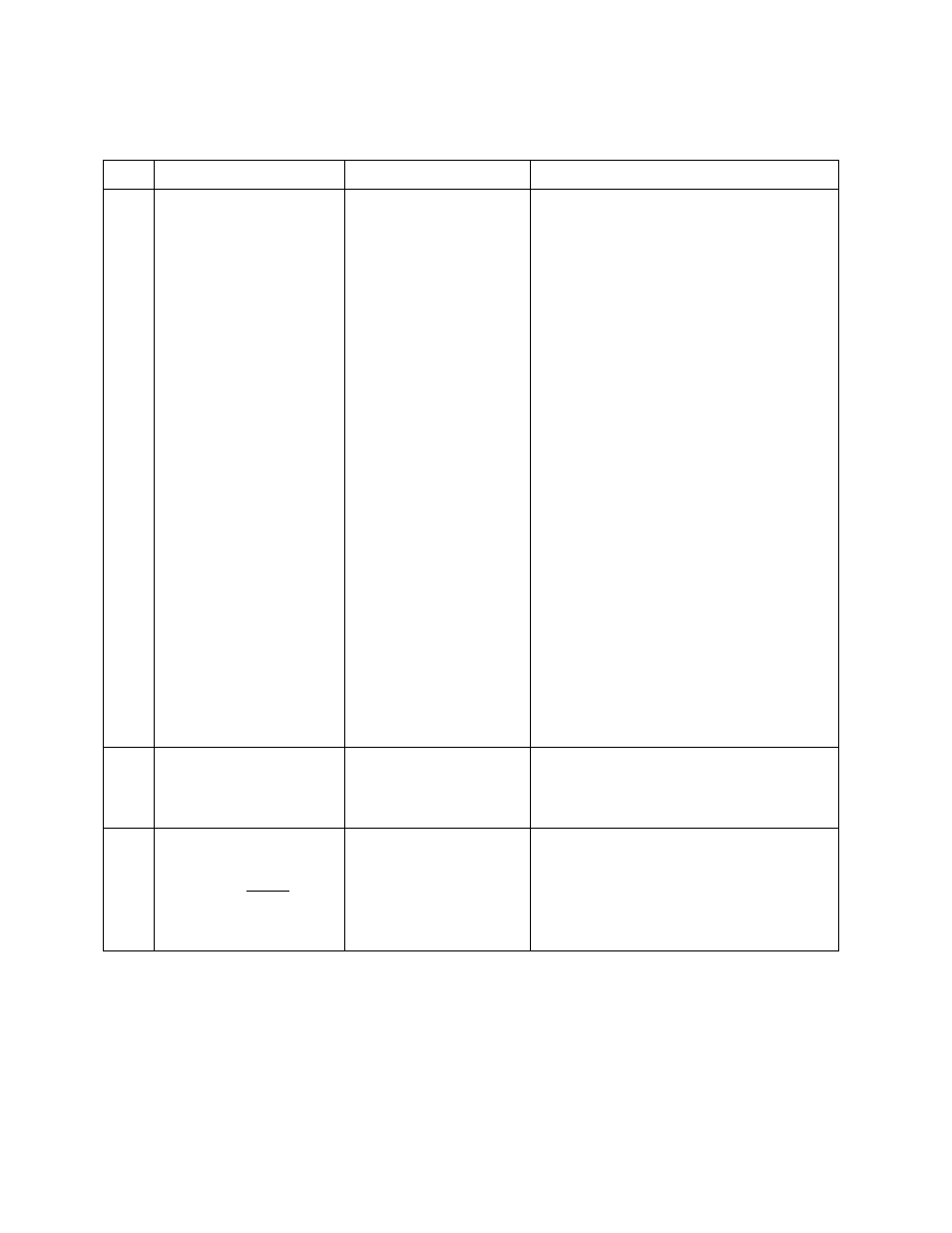

TABLE 7-1. TROUBLESHOOTING – CONTROL VALVE CXT-E (Continued)

NO.

FAULT INDICATION

PROBABLE CAUSE

CORRECTIVE ACTION

T3

(Continued)

3. Steam pressure, or

heating fluid

temperature too low.

4. For Steam Heating

System, Trap or

Orifice in Heater

Condensate Line is

malfunctioning.

3. Check the high side steam pressure to

the Control Valve to ensure it is correct.

For high temperature (HT) water,

ensure there is good circulation.

a. If steam pressure or HT water

temperature is lower than the system

design spec., correct as necessary.

b. If high side steam pressure drops, or

there is no HT water circulation as

the Control Valve opens, there may

be a partially closed valve in the

upstream line. Also, the strainer may

be clogged. Correct as needed.

4. Check for improper operation of Trap or

clogged Orifice in Condensate Line as

follows:

a. If low side pressure gauge shows

pressure but steam does not heat

properly, CAREFULLY break

Condensate Line connection AHEAD

of Trap or Orifice.

b. Allow condensate to run out into floor

drain.

c. If Heater outlet temperature rises to

desired setpoint with condensate

connection open, repair or replace

Trap or unplug Orifice.

T4

Wide variations in

Heater outlet temper-

ature during wide

variations in flow .

1. System not properly

sized to maintain

desired setpoint.

1. Review system flow characteristics to

ensure Heat Exchanger and Valve are

properly sized to maintain the desired

outlet temperature.

T5

Rapid fluctuations in

heater outlet temper-

ature which do not follow

load changes

1. Temp. Controller

sensitivity not set

correctly

2. Steam System Trap

or Orifice fault

1. Adjust Temp. Controller sensitivity

2. Refer to T3, Corrective Action 4 above

and proceed as indicated.