AERCO Electronic Control Valve User Manual

Page 22

VA-115 INSTRUCTIONS – ELECTRONIC CONTROL VALVE, CXT-E

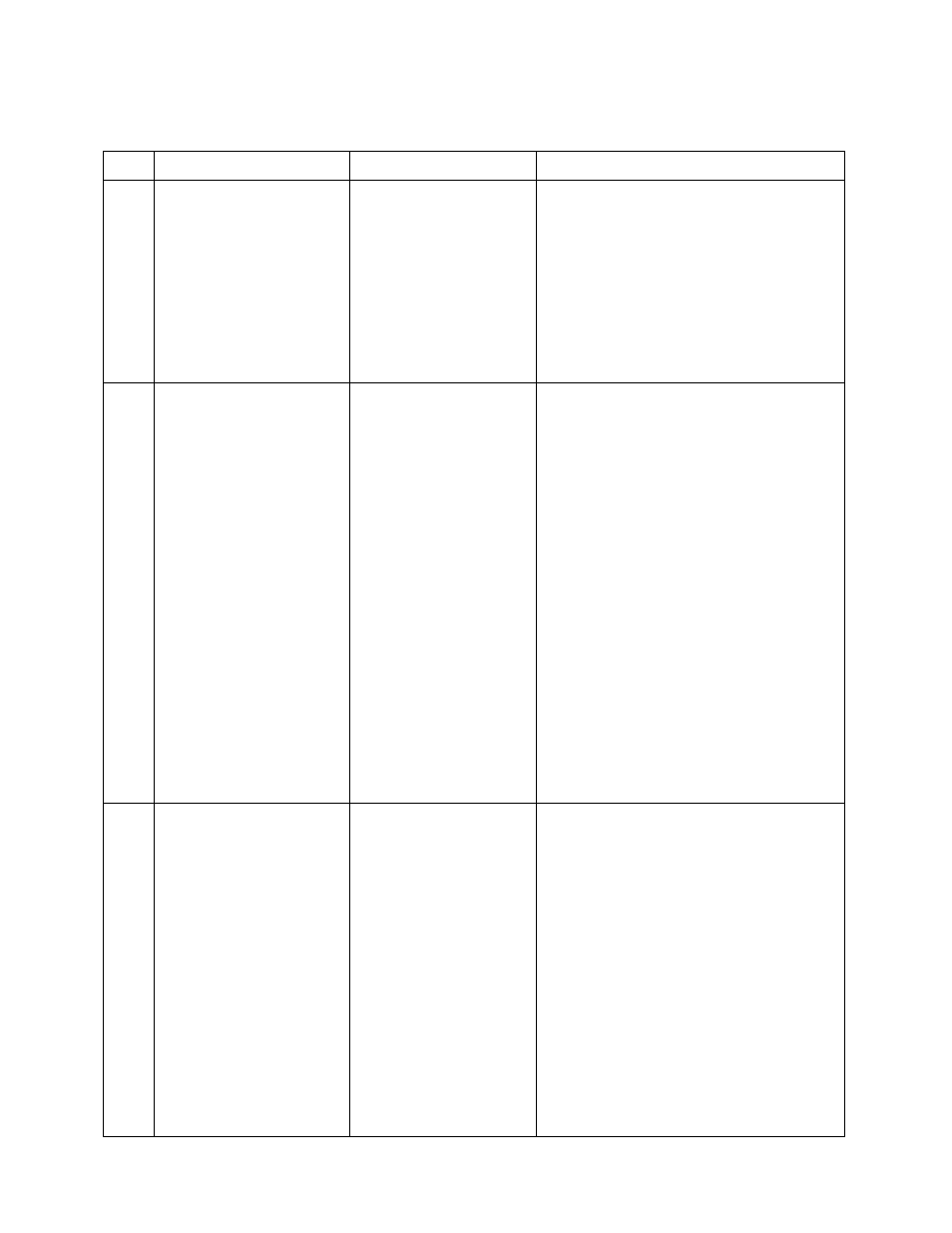

7-2

TABLE 7-1. TROUBLESHOOTING – CONTROL VALVE CXT-E

NO.

FAULT INDICATION

PROBABLE CAUSE

CORRECTIVE ACTION

T1

System not operating.

Control Valve is closed

and outlet water temp. is

far below setpoint.

1. No power supplied to

Control Valve

2. Control signal not

being supplied from

Temp. Controller.

1. Disconnect Valve Actuator plug and

verify that 24 VDC power is present at

pin 2 of Actuator cable. Restore power

if necessary. If System includes an

over-temp limiting device, ensure that it

has not tripped.

2. Verify presence of 4 - 20 mA control

signal at pin 3 of Actuator cable. If

control signal is not present,

troubleshoot Temp. Controller.

T2

System over-heats by

more than 10°F above the

desired setpoint.

Outlet temp is below Over-

Temp limit setting

CAUTION

Over-tightening the Pack-

ing Nut may trap the Valve

Stem and slow or stop

Valve motion.

1. Control Valve not fully

closed.

2. Temp. Controller not

set properly or

defective.

3. Valve Actuator not

properly secured to

Linkage Assembly.

4. Foreign matter in

Valve Seat.

1. Check the 4 – 20 mA control signal

being supplied to Actuator. If signal is

greater than 4 mA when heater outlet

temperature is 10°F (or more) above

the desired setpoint, proceed to next

item in list.

2. Check the current setting of Temp.

Controller providing the 4 – 20 mA

control signal to the Valve Actuator.

Readjust if necessary. If adjustment

does not clear fault, troubleshoot the

Controller.

3. Check Actuator U-bolt securing it to

Linkage Assembly. Tighten if needed

and readjust the CXT-E Control Valve

per Section 3.

4. If Valve still does not close after

checking the above items, disassemble

the Valve and clean the Seat per steps

CM18 – CM28 in Section 8. Readjust

the CXT-E Control Valve per Section 3.

T3 System

outlet

water

temperature is below

desired setpoint

CAUTION

Over-tightening the Pack-

ing Nut may trap the

Valve Stem and slow or

stop Valve motion.

1. Temp. Controller not

properly set.

2. Control Valve not

opening properly.

1. Check the current setting of the Temp.

Controller. If the setting is below the

desired setpoint, readjust as necessary.

2. Check as follows:

a. Ensure Actuator is secured to

Linkage Assembly. Tighten if needed

and readjust the CXT-E Control

Valve per Section 3.

b. Verify that 24 VDC power and 4 – 20

mA control signal are present at

Actuator pins 2 and 3 respectively.

c. To ensure Valve is not binding,

check Seal Retainer per steps CM1-

CM10 of Section 8 Corrective

Maintenance. Replace items as

necessary.