5 supply and return piping, 6 condensate drain and piping, Installation – AERCO BMK 2.0 LN Natural Gas 2008 User Manual

Page 13

INSTALLATION

2-3

If installing a Combination Control Panel (CCP)

system, it is important to identify the

Combination Mode Boilers in advance and place

them in the proper physical location. Refer to

Chapter 5 for information on Combination Mode

Boilers.

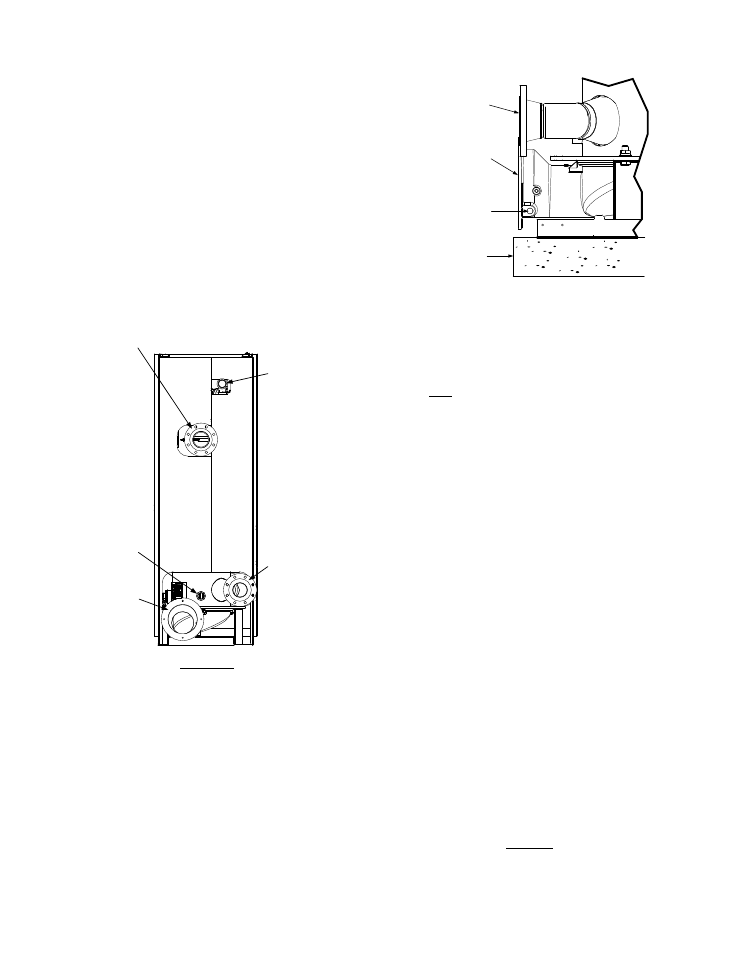

2.5 SUPPLY AND RETURN PIPING

The Benchmark 2.0LN Boiler utilizes 4” 150#

flanges for the water system supply and return

piping connections. The physical location of the

supply and return piping connections are on the

rear of the unit as shown in Figure 2-3. Refer to

Appendix F, Drawing AP-A-841 for additional

dimensional data.

2" GAS INLET

CONNECTION

BOILER RETURN

4" – 150# FLANGE

CONNECTION

BOILER SUPPLY

4" – 150# FLANGE

CONNECTION

EXHAUST

MANIFOLD

SHELL

DRAIN

VALVE

REAR VIEW

Figure 2-3

Supply and Return Locations

2.6 CONDENSATE DRAIN AND PIPING

The Boiler is designed to condense water vapor

from the flue products. Therefore, the installation

must have provisions for suitable drainage or

collection. A 1/2” NPT drain connection is

provided on the exhaust manifold as shown in

Figure 2-4.

EXHAUST

MANIFOLD

1/2” NPT

CONDENSATE

DRAIN

CONNECTION

HOUSE-

KEEPING

PAD

BOILER

RETURN

Figure 2-4

Condensate Drain Connection Location

A separate condensate drain trap (part no.

24060) is shipped loose and must be installed

on the floor behind the unit. Connect the trap to

the exhaust manifold as follows:

1. First, install a 1/2” NPT nipple in the

condensate drain port shown in Figure 2.4.

2. Next, connect a 3/4-to-1/2” reducer to the

1/2” nipple.

3. Refer to Figure 2-5 and connect the

condensate drain trap to the exhaust

manifold as described in steps 4 through 7.

4. On the condensate drain trap, install 3/4”

NPT nipples in the tapped inlet and outlet of

the trap.

5. Attach a length of 1” I.D. polypropylene hose

between the exhaust manifold drain and the

inlet side of the condensate trap (Fig 2.5).

Secure both ends of the hose with clamps.

6. Connect a second length of 1” I.D. hose to

the outlet side of the condensate trap and

route it to a nearby floor drain.

7. Drainage from the condensate drain trap

outlet must be by gravity to a nearby floor

drain.

If a floor drain is not available, a condensate

pump can be used to remove the condensate to

drain. The maximum condensate flow rate is 20

GPH. The condensate drain trap, associated

fittings and drain line must be removable for

routine maintenance. DO NOT hard pipe.