Checkline TD-1-TE User Manual

Page 3

-3-

2 .0 O

V ERV I EW OF T H E

T D-1 -T E I

N DI CAT OR

3 .0 R

EM OV I N G AN D

M

OU N T I N G T H E

F

RON T

C

OV ER

1

2

3

4

2

5

6

7

8

3

9

10

XXX.X

X.XXX

XX.XX

0

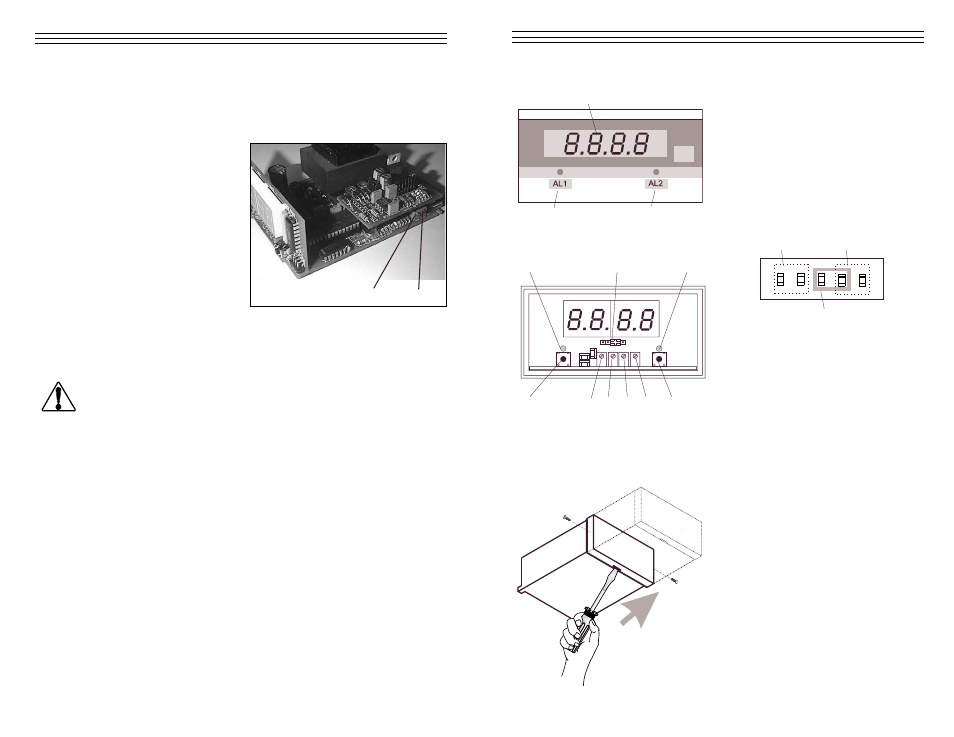

1

= Digital

display

0

2

=

Light emitting diode for low

alarm limit

0

3

=

Light emitting diode for high

alarm limit

0

4

=

Decimal point jumper no jumper

set of decimal point XXXX

0

5

=

Pushbutton for low alarm limit

0

6

=

Potentiometer for low alarm

limit

0

7

= ZERO

potentiometer

0

8

= GAIN

potentiometer

0

9

=

Potentiometer for high alarm

limit

10

=

Pushbutton for high alarm limit

Screw

Screw

Removing: Remove the two screws

Insert a screwdriver with a point width

of 4mm in the slot at the bottom of the

housing and carefully push the front

cover away from the panel in the

direction of the arrow.

Mounting: Carefully push the front

cover onto the housing in the opposite

direction of the arrow.

2. Hang a weight that corresponds to 10% of the tension range (pay attention

to the correct unit of measure) from the measured material, vertically, as

shown in the figure on page 12. (Always use a fresh portion of the

material to be measured.)

3. Adjust the potentiometer (13)

using a screw-driver with a

point width of up to 2mm

until the display of the

voltmeter connected to the

Analog interface reads

0.1 volts

-14-

13

14

GAIN Adjustment Procedure

1. Perform a Zero adjustment.

2. Thread the process material through the measuring rollers.

When threading the process material through the rollers, follow the

material path symbol on the front of the sensor. If a force is applied

to the middle sensor roller in the incorrect direction, damage could

result.

NOTE:

Since zero and gain adjustments are always performed

statically, the display values may differ under dynamic load.

3. Hang a weight that corresponds to 95% of the tension range (pay

attention to the correct unit of measure) from the measured material,

vertically as shown in the figure on page 12. (Always use a fresh

portion of the material to be measured.)

4. Adjust the potentiometer (14) using a screwdriver (with a point width

of up to 2mm) until the display of the voltmeter connected to the

Analog interface reads 9.5 volts.

Check the setting and repeat the procedure if necessary.

WARNING