4 feed tube, selection, 5 liquid feed rate, adjustment, 6 cooling gas, adjustment – BUCHI Ultrasonic Package User Manual

Page 27

BÜCHI Labortechnik AG

Installation | 5

Ultrasonic Controller

27/46

5.4 Feed tube, selection

1.

Choose a feeding tube from the table below.

NOTE

For short processes, even unsuitable tubes can be used, as swelling takes

some time.

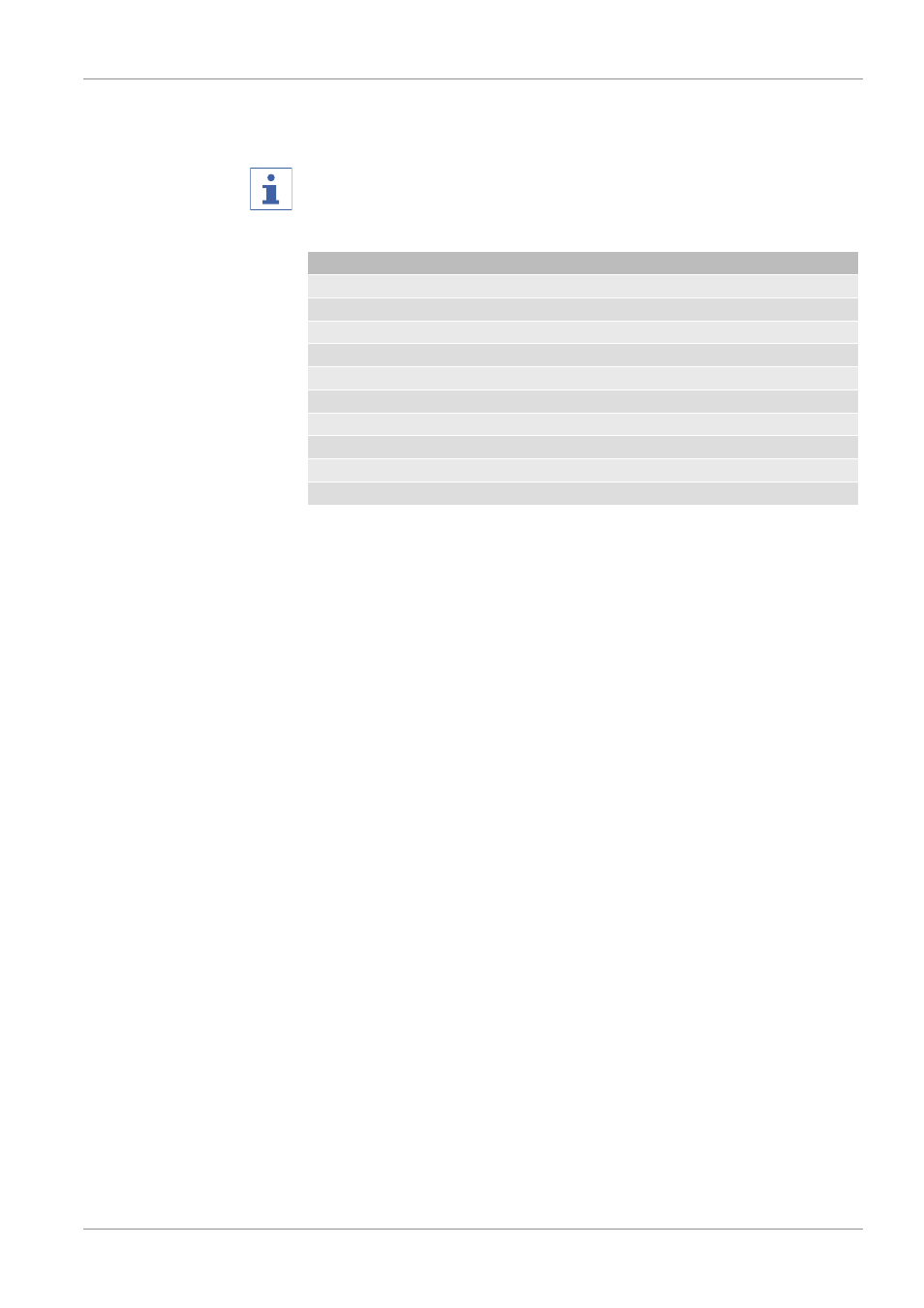

Solvent

Silicone tube

Tygon

®

MH 2075 Tygon

®

F 4040 A

Methanol

•

•

•

Ethanol

•

•

•

Acetone

–

•

–

Toluene

–

–

–

Isopropanol

•

•

•

Chloroform

–

–

–

Dichlormethane

–

–

–

Tetrahydrofuran

–

–

–

Ethylacetate

–

•

–

Hexane

–

–

•

Table 1: • = suitable | – = unsuitable

5.5 Liquid feed rate, adjustment

1.

Adjust the feed rate according to the following settings according to the

desired requirement:

• Possible liquid feed rate using ultrasonic nozzle 1–9 mL/min (3–30 %).

• Recommended feed rate with aqueous feeds 2.5–3.2 mL/min (8–10 %).

5.6 Cooling gas, adjustment

Adjust the flow rate of the cooling gas using the needle valve at the flow meter

of the B290.

The temperature of the ultrasonic nozzle shall always be below 100 °C. If the

temperature of the ultrasonic nozzle rises (the temperature can be checked on

the upper display of the ultrasonic controller), the flow rate of the cooling gas

needs to be increased.