1 nozzle, power settings – BUCHI Ultrasonic Package User Manual

Page 18

4 | Description of function

BÜCHI Labortechnik AG

18/46

Ultrasonic Controller

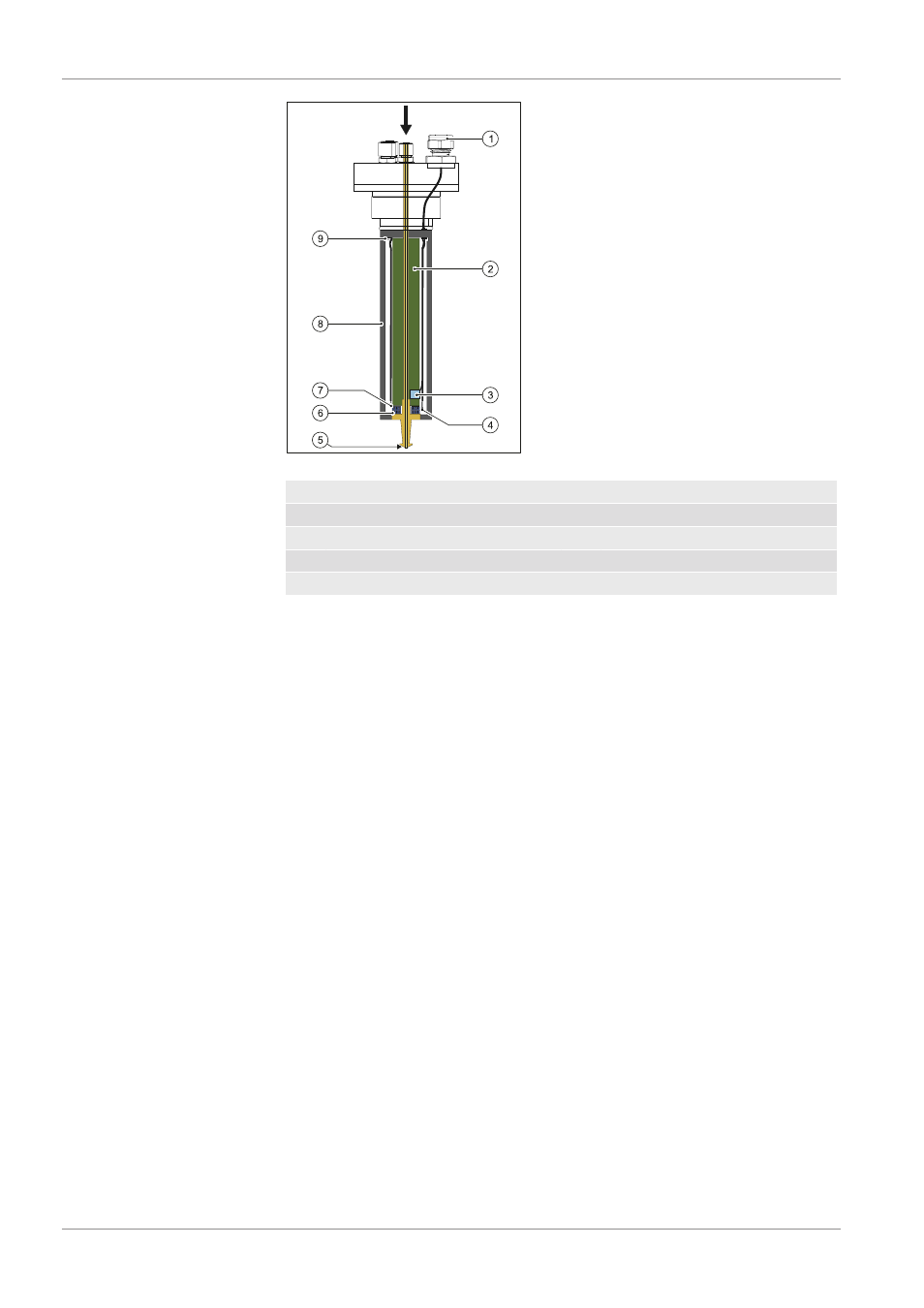

Fig. 4: Nozzle design (schematic)

1

Electrical connector

2

Rear horn

3

Temperature sensor

4

Active electrode

5

Atomizing surface

6

Piezoelectric transducer

7

Ground electrode

8

Housing

9

Ground lug

Discshaped ceramic piezoelectric transducers convert high frequency electrical

energy from a power generator into vibratory mechanical energy at the same

frequency.

The transducers are sandwiched between 2 titanium cylinders, which act to

concentrate and amplify the vibration, maximizing it at the atomizing surface. Ti

tanium is used because of its good acoustical characteristics, corrosionresis

tance and high strength.

The liquid is delivered to the atomizing surface through a large diameter feed

tube that runs the length of the nozzle. The large liquid feed orifice assures free

dom from clogging.

4.2.1.1 Nozzle, power settings

The ultrasonic atomization process is highly dependent on the power delivered

to the nozzle. Best results are achieved within a relatively narrow input power

range. Below a critical power level, referred to as the “stall point”, there is insuf

ficient energy to produce atomization. The power range in which atomization

proceeds normally is generally confined to a narrow region, approximately 0.5–

1.5 Watt above the stall point. At power levels above this range, the liquid is lit

erally “ripped apart” by the excess energy provided, causing large chunks of

material to be expelled, rather than the characteristic soft spray of fine drops.

This condition is known as cavitation.

The actual power at which the stall point occurs is dependent on several fac

tors:

• Nozzle type (mechanical and electrical characteristics, size)

• Liquid characteristics (e.g. viscosity, solids content)

• Flow rate

• Size of the atomizing surface