3 drop size distribution – BUCHI Ultrasonic Package User Manual

Page 20

4 | Description of function

BÜCHI Labortechnik AG

20/46

Ultrasonic Controller

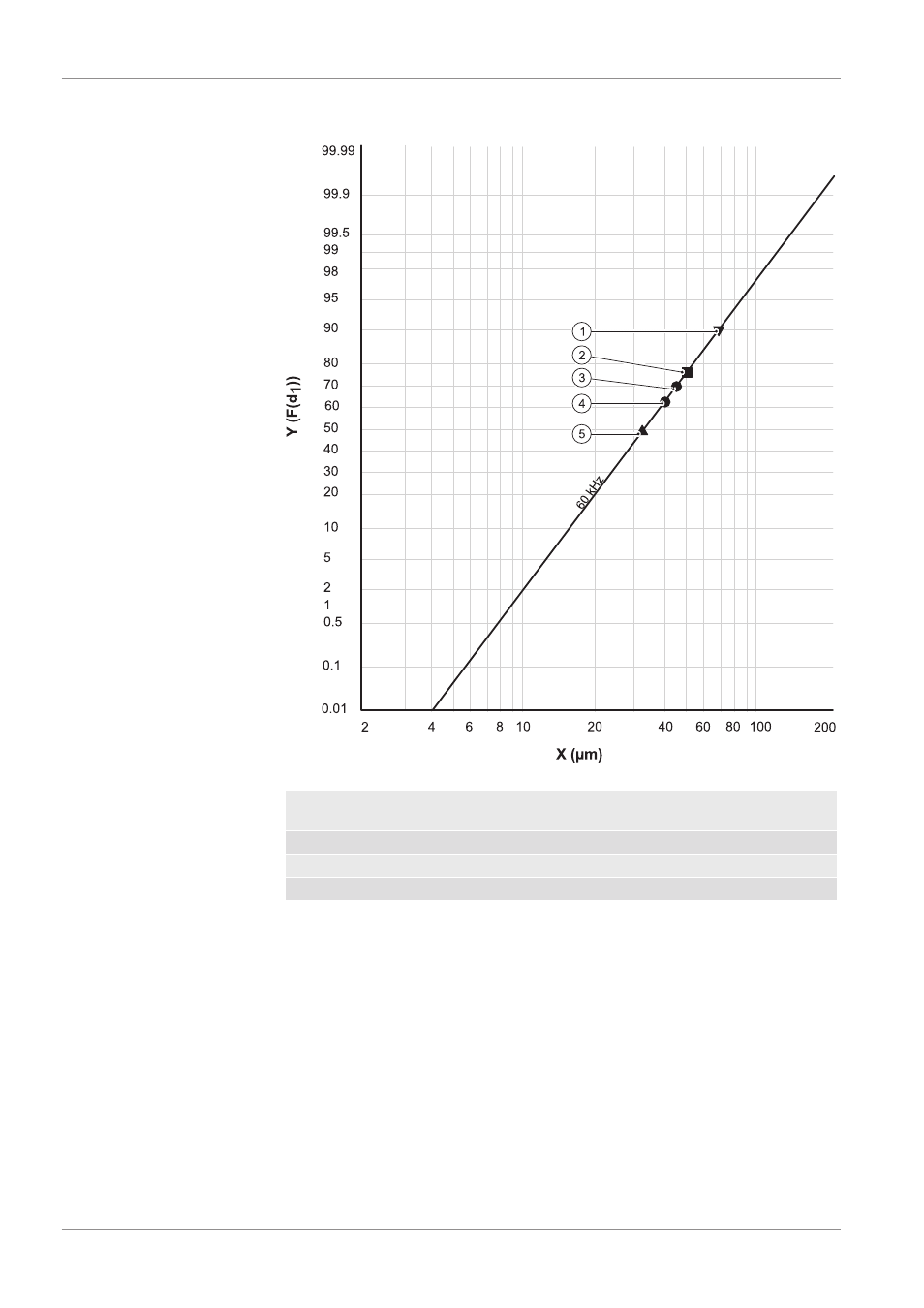

4.3 Drop size distribution

Fig. 5: Drop size distribution

X

Drop diameter (microns)

Y

Percent of drops below given di

ameter

1

Sauter mean diameter

2

Weight mean diameter

3

Surface mean diameter

4

Number mean diameter

5

Number median diameter

Drop size in an ultrasonically produced spray is governed by the frequency at

which the nozzle vibrates, and by the surface tension and density of the liquid

being atomized. However, frequency is the predominant factor. Median drop

size is inversely proportional to frequency to the 2/3 power. Thus, the higher the

frequency the smaller the median drop size.

Typically, the drop size distribution from ultrasonic nozzles follows a lognormal

distribution curve. In simple terms, this distribution has the familiar bellshape

but on a logarithmic scale. The chart shows this distribution on a cumulative ba

sis for several nozzle frequencies for water.

Various parameters can be used to characterize the mean and median drop

size of a particular drop distribution. The number median diameter defines the

50 % point in drop size – that is, onehalf of the number of drops in the spray

have diameters larger than this value while the other half have diameters

smaller than this value. The number mean and weight mean diameters are av

erage diameters. The number mean diameter is obtained by adding together

the diameter of each drop in a spray sample and dividing that sum by the num