Vii. remote operation using rheocalc, Viii. error messages and failsafes – Brookfield Temperature Controller, Model 106 User Manual

Page 21

Brookfield Engineering Labs., Inc.

Page 2

Manual No. M/02-207-C009

s

t

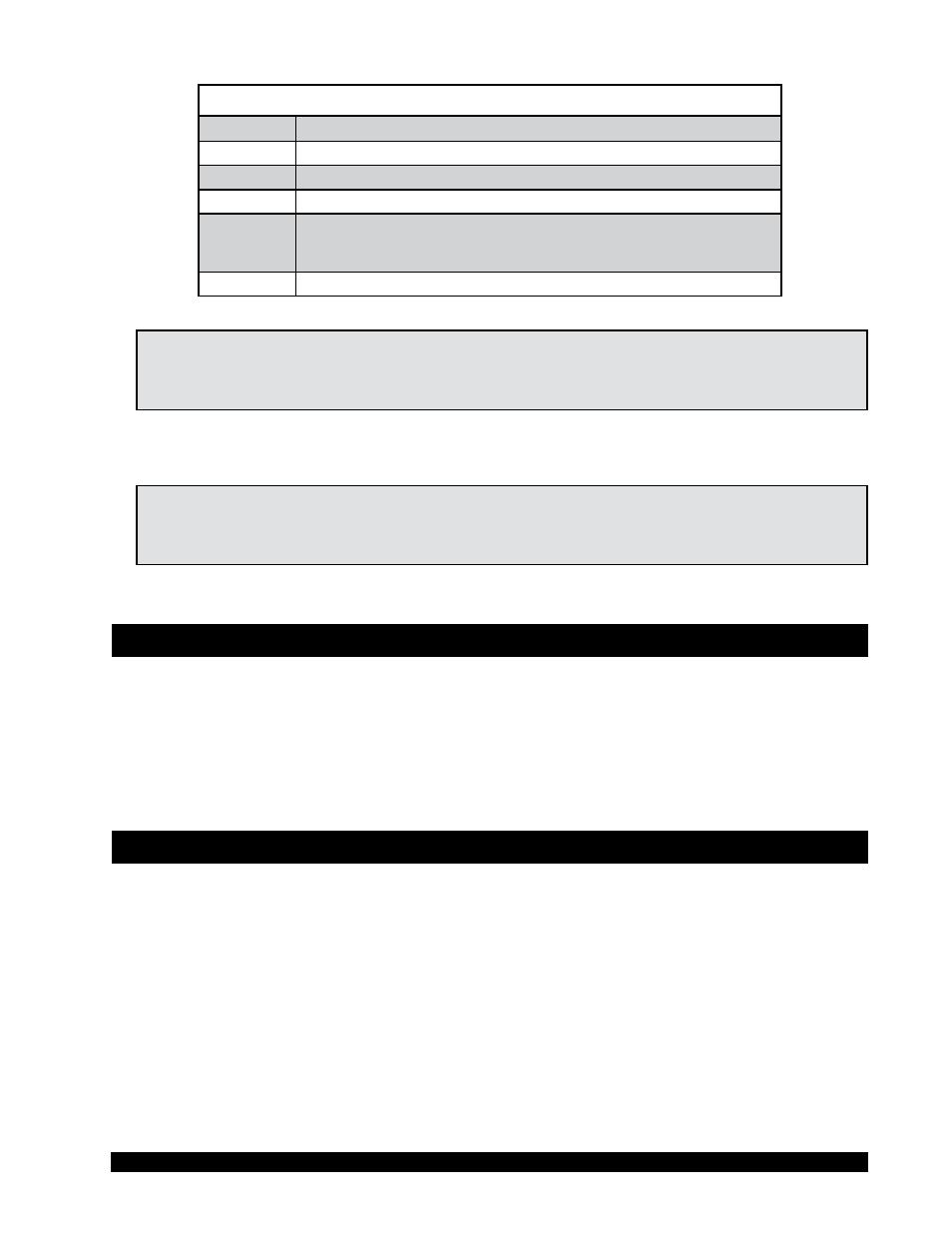

Codes Defining the State of the Programmable Temperature Controller

Code

Definition

1

RUN mode; control to the setpoint temperature

2

STANDBY mode; do not control; wait for further input

3

Probe error 1 (probe disconnected from controller)

4

Overheat of the Thermo Container. This occurs after approximately 3

minutes of constant heat with no sensed temperature rise in the Thermo

Container.

5

Probe error 2 (temperature reading is above allowable limit)

Table VI.2

NOTE:

Only codes

and

2

will be accepted by the Programmable Temperature Controller.

Codes

3, 4

and

5

are indications only. All five codes may be returned by the Program-

mable Temperature Controller to the connected device (i.e. PC or terminal).

Any command other than those listed above sent to the Programmable Temperature Controller

will cause the controller to respond with a question mark

(?{CR}).

NOTE: Temperature/Time programs entered in stand-alone mode (i.e. from the Programmable Tem-

perature Controller front panel) cannot be executed in the external mode via the RS-232C port.

The commands explained above are the only means with which to control the Programmable

Temperature Controller.

VII. REMOTE OPERATION USING RHEOCALC

©

RHEOCALC

©

, a software program available from Brookfield Engineering Laboratories that con-

trols the operation of the Brookfield DV-II+ PRO Viscometer and the DV-III+/DV-III Ultra

Rheometer, can also be used concurrently to control the Programmable Temperature Controller in

its external mode.

VIII. ERROR MESSAGES AND FAILSAFES

If the display shows an error message or there is a continuous “beeping” from the piezo buzzer,

you are in one of the following error conditions:

1) The probe has become disconnected from the Programmable Temperature Controller.

Plug the probe back in to the Programmable Temperature Controller to correct the error.

2) The controller is providing power to the Thermo Container, but the temperature sensor

is not reporting an increase in temperature. The power to the Thermo Container will be

interrupted. It will be necessary to power down the Programmable Temperature Control-

ler and determine the cause of the fault before continuing operation.