Brookfield EZ User Manual

Ez-lock spindle coupling system

B R O O K F I E L D E N G I N E E R I N G L A B O R AT O R I E S , I N C .

11 C o m m e r c e B o u l e v a r d

•

M i d d l e b o r o , M A 0 2 3 4 6 U S A

ISO9001 CERTIFIED

T

E L

5 0 8 - 9 4 6 - 6 2 0 0 o r 8 0 0 - 6 2 8 - 8 1 3 9 F

A X

5 0 8 - 9 4 6 - 6 2 6 2

w w w . b r o o k f i e l d e n g i n e e r i n g . c o m

Boston • Chicago • London • Stuttgart • Dresden • Guangzhou

EZ-Lock Spindle Coupling System

Operator Instructions for Built-in and Retrofitted Systems

M07-231-B0513

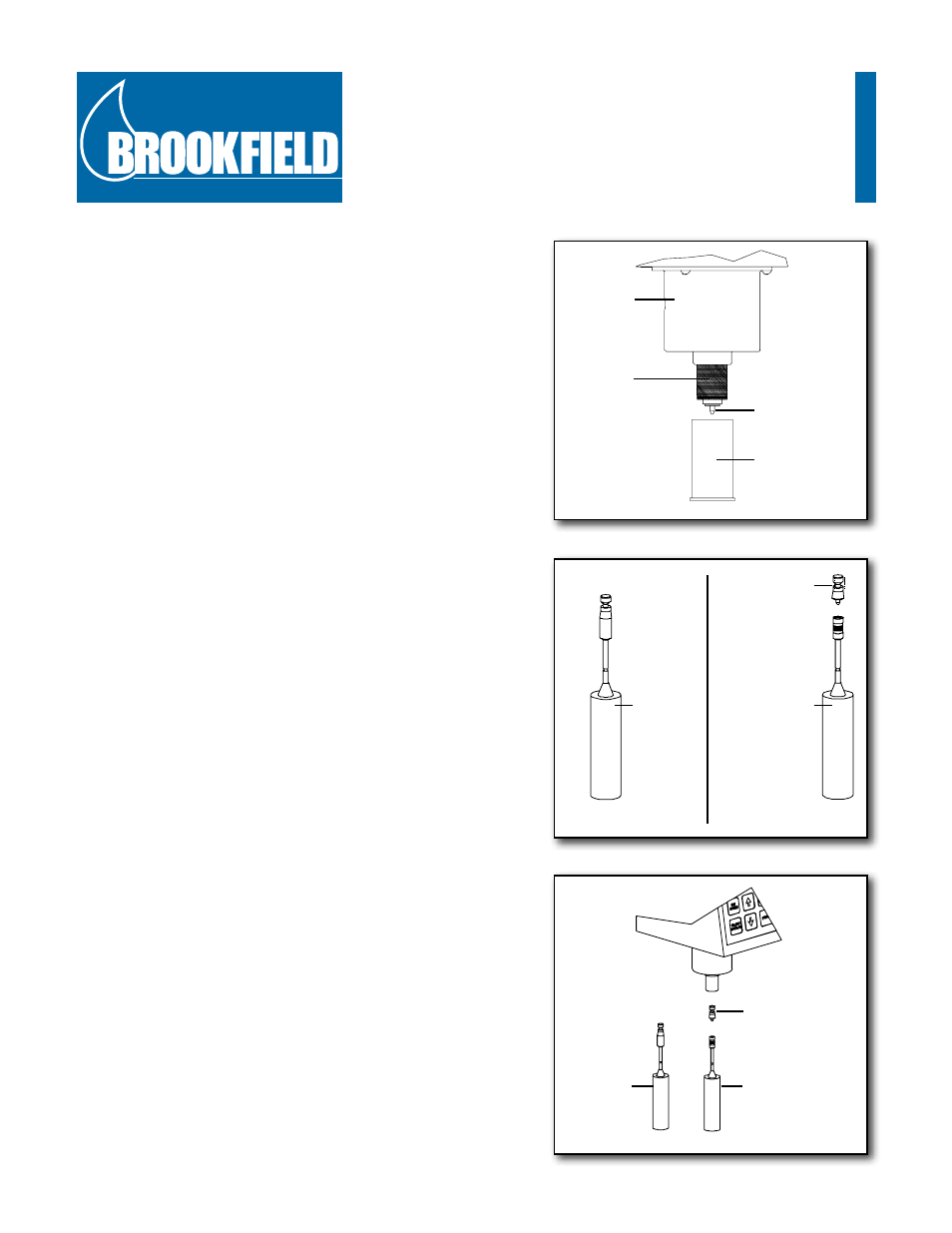

I. SET UP

Carefully remove the protective shipping cap with foam insert

(Part No. B-30KY) by gently pulling from the bottom. Retain

for future use.

> If your instrument has been

retrofitted with an EZ-Lock

Spindle Coupling System, proceed to Section I.1.

> If your instrument was purchased with an EZ-Lock

Spindle Coupling System built-in (the spindle coupling

is permanently attached to the spindle), proceed to Section

II.

I.1. EZ-Lock Spindle Coupling Retrofit System

(with spindle coupling adapter)

The EZ-Lock Spindle Coupling (Part No. YU-20C) has

been attached to the viscometer prior to shipment. To

remove for attachment to a spindle, hold onto the bottom

of the EZ-Lock Spindle Coupling with one hand while

raising the spring-loaded outter sleeve up towards the

viscometer pivot cup with the other hand. The spindle

coupling should easily slide out and can now be connected

to a spindle. Note left hand threads!

II. ATTACHING SPINDLE WITH EZ-LOCK COUPLING

With one hand, hold the spindle while gently raising the spring-

loaded outer sleeve to its highest position with the other hand.

Insert the EZ-Lock Spindle Coupling and lower the sleeve.

The sleeve should easily slide back down to hold the spindle/

coupling assembly in place for use.

NOTE: Keep the EZ-Lock Spindle Coupling and outer sleeve as clean as

possible and free from debris that could become lodged inside the

adapter.

III. OPERATION

Follow normal instrument operating procedures (refer to

operator manual).

NOTE: Special guard legs are needed to accommodate the length of the

spindle coupling system and are supplied with all built-in and

retrofitted systems at initial purchase. Accessories used with

EZ-Lock (SSA, ULA, Thermosel, DIN Adapter) require a special

Alignment Bracket (also known as Locating Channel) with a longer

length.

IV. REMOVING SPINDLE WITH EZ-LOCK COUPLING

Hold the spindle with one hand, while gently pushing the

spring-loaded outer sleeve upwards with the other. The spindle/

coupling assembly should easily slide out.

Shipping Cap

(

Part No. B-30KY

)

Outer

Sleeve

Viscometer

Pivot Cup

EZ-Lock Spindle

Coupling

EZ-Lock Spindle

Coupling

(

Part No. YU-20C

)

Standard

Spindle

(typical)

EZ-Lock Spindle

Coupling

(Part No. YU-20C)

Standard

Spindle

(typical)

Built-in System

Retrofitted System

EZ-Lock

Spindle

(typical)

EZ-Lock

Spindle

(typical)