B.5.4 flow diagram for zero calibration – Brookfield R/S CPS Rheometer User Manual

Page 59

Brookfield Engineering Labs., Inc.

Page 59

Manual No. M08-218-B0212

Other Faults

Indication

Possible Cause

Solution

Dial indicator reading

is inconsistent.

Set pin has lost hold power.

Pin may need to be replaced. Call for

service.

Viscosity reading is

low.

Micrometer ring was not lined

up with zero on shaft. Head

is too high.

Ensure spindle is not mounted to

R/S. Re-try zero calibration. If it

fails, call for service.

Viscosity reading

is low and spindles

does not mvoe freely

when hex nut is

disengaged.

Contamination has entered

the gap between the spindle

cone piece and spindle shaft.

Loosen set screw. Extend spindle

to maximum length. Clean shaft.

Repeat if needed. If the spindle can-

not be cleaned sufficiently, call for

service of spindle.

Viscosity reading is

low.

Rheometer has been placed

in a drafty location.

Utilize solvent trap; shield unit from

drafts.

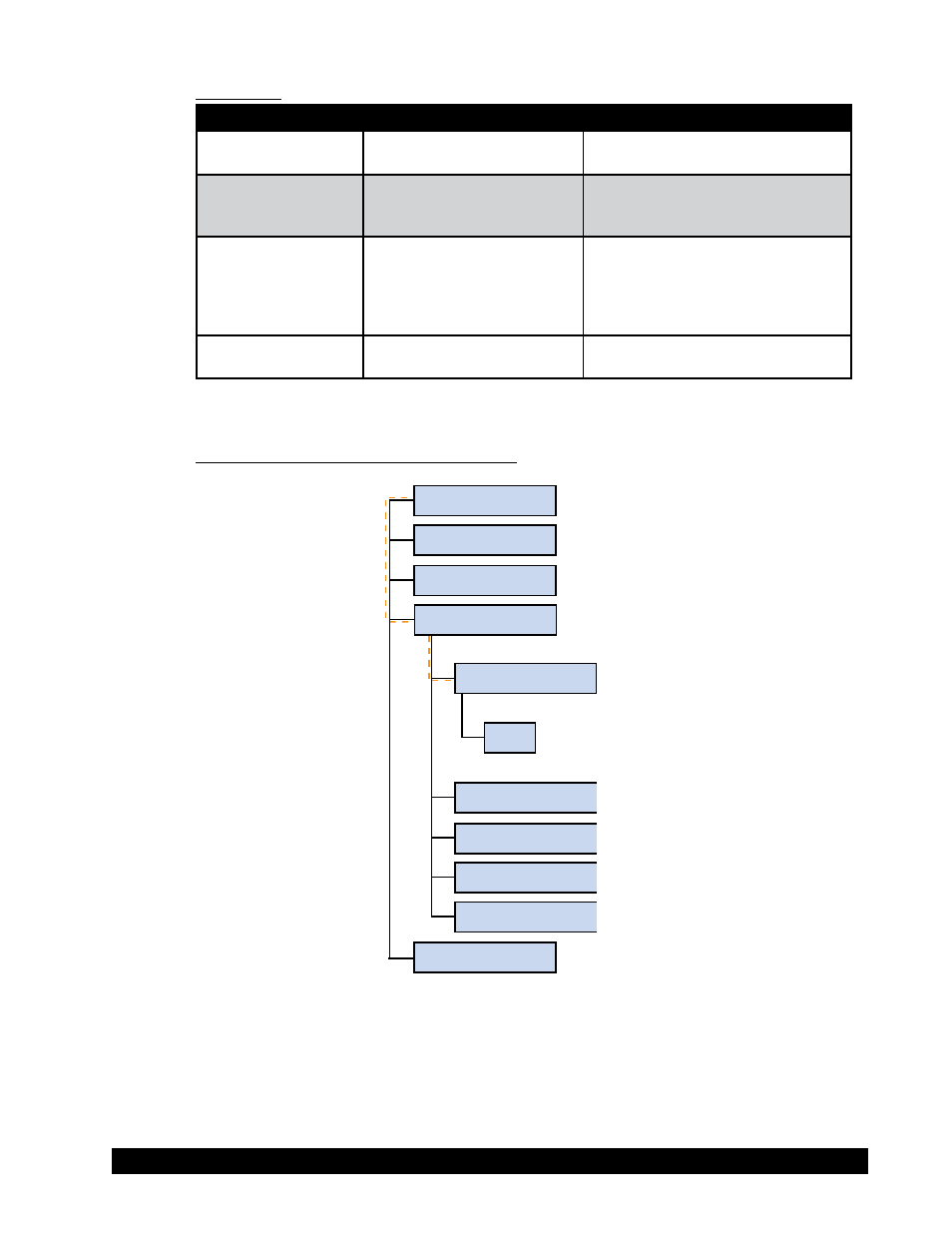

B.5.4 Flow Diagram for Zero Calibration

Zero-Calibration

OK

Utilities

Edit Programs

Print Programs

Measuring System

Print Memory

Run Program

Remote

Configuration

Run Single