Appendix b calibration check procedure, B.1 equipment, B.2 setup prrocedure – Brookfield R/S CPS Rheometer User Manual

Page 54

Brookfield Engineering Labs., Inc.

Page 54

Manual No. M08-218-B0212

• R/S-CPS+ Cone/Plate Rheometer with appropriate cables

• Temperature control apparatus

1

• Flat edged non-metal spatula

• Cone Spindle and Certified Mineral Oil Viscosity Standard:

One of the following

2

:

- RC3-25-1 Cone Spindle with Fluid B41000

- RC3-50-1 Cone Spindle with Fluid B11000

- RC3-50-2 Cone Spindle with Fluid B41000

- RC3-75-1 Cone Spindle with Fluid B4900

- RC3-75-2 Cone Spindle with Fluid B4900

• Rheo 3000 Applications Software loaded onto a PC (optional)

Reminders/Comments:

• A calibration check can be performed with or without software.

• The rheometer should always be allowed 10 minutes minimum to warm up.

• Never lift your rheometer by the head, shaft, coupling element, or measuring element

coupled to the machine.

• After the spindle has been lowered onto a sample, detach the spindle from the rheometer

head before raising the head.

• Total time to perform a calibration check is approximately 50 minutes.

1

Temperature Control apparatus consists of one of the following: Peltier System, Water bath, Oil Bath or Electronic Heat

2

Calibration check using either an RC3-25-1 or RC3-25-2 is not advised. To achieve the best results, use RC3-50-1.

•

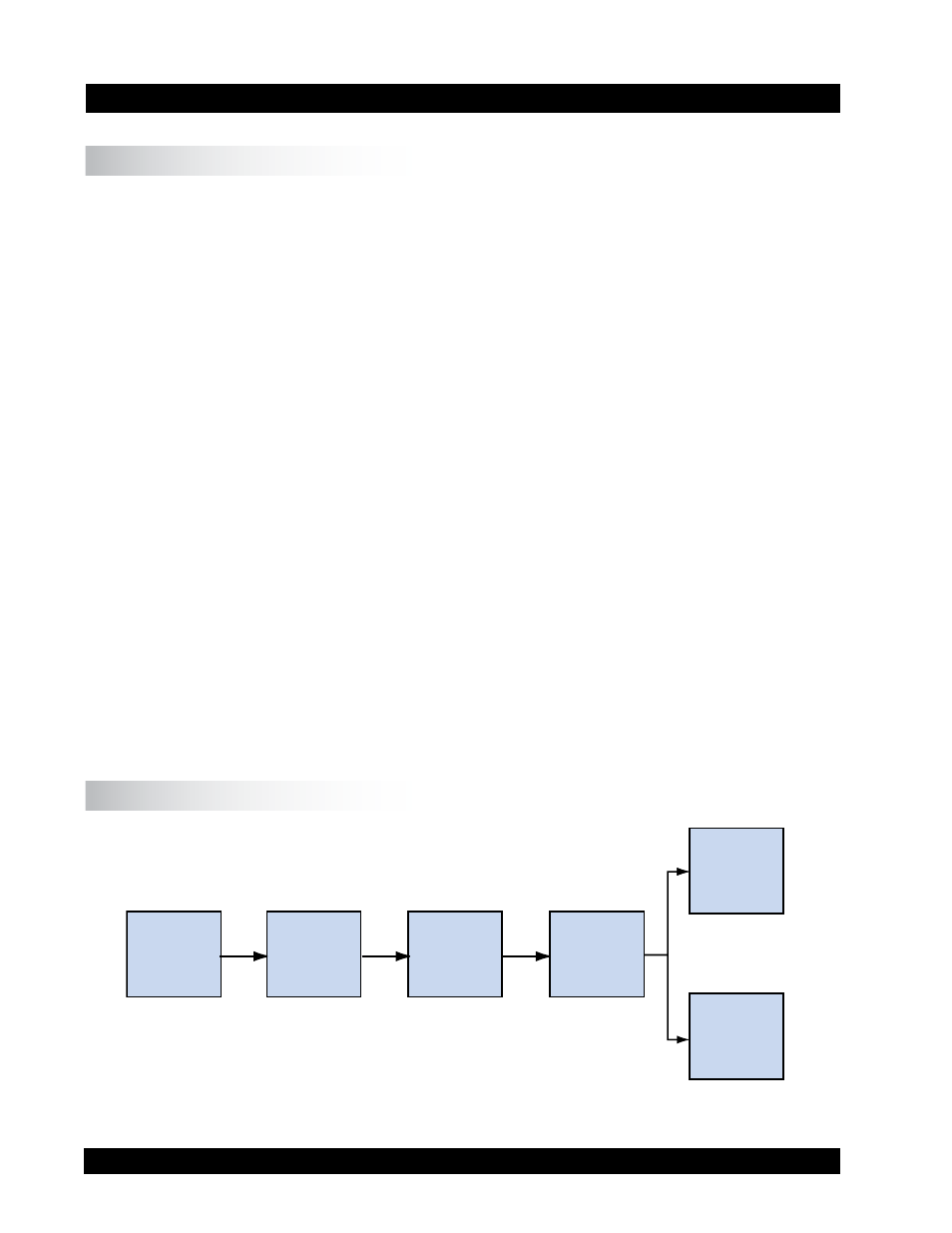

Start Up

Rheometer

Load the

Viscosity

Standard

Zero

Rheometer

Set the Gap

Calibration

Check in

Stand-alone

Mode

Calibration

Check

Using

Rheo2000

Figure B-1: Flow Chart for Calibration Check Procedure

Appendix B Calibration Check Procedure

B.1 Equipment

B.2 Setup Prrocedure