Chemtronics Soder-Wick Unfluxed SD 75-4-10 User Manual

Technical data sheet, Soder-wick, Desoldering braid

PRODUCT DESCRIPTION

Soder-Wick

offers the state of the art in

desoldering technology. Soder-Wick

is

designed for today’s heat sensitive

electronic components using lighter mass,

pure copper braid construction that allows

for better thermal conductivity, even at low

temperatures. Soder-Wick

responds faster

than conventional desoldering braids

thereby minimizing overheating and

preventing PCB damage. A full range of

sizes and flux types are available, including

Rosin, No Clean, unfluxed and a high

temperature Lead-Free version. Whatever

the requirement, Soder-Wick

has the

answer.

Requires little or no post solder cleaning

No corrosive residues

Optimized construction for faster

wicking and heat transfer

Halide free

Minimizes the risk of heat damage to

components and circuit boards

TYPICAL APPLICATIONS

Soder-Wick

desoldering braid safely

removes solder from:

Thru-hole Components

SMT Pads and BGA Pads

Micro Circuits

Terminals

Lugs and Posts

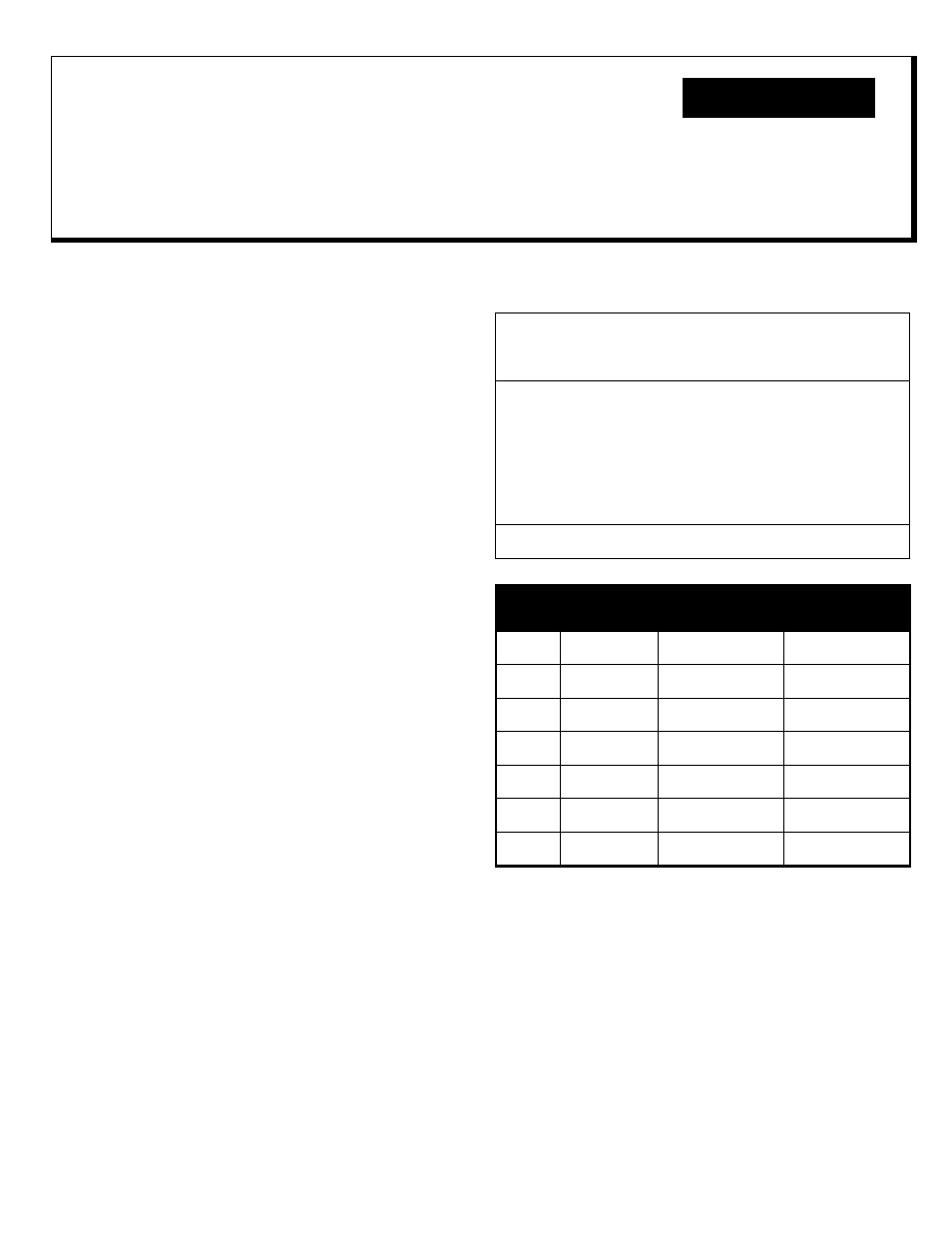

Identification Script

TYPICAL PRODUCT DATA AND

PHYSICAL PROPERTIES

Flux Types: Rosin Grade WW, Type “R”

Patented No Clean

High Temperature No Clean

Specifications: ANSI/IPC J STD-004

MIL-F-14256 F

No Clean Flux Spec: MIL-STD-883B

Bellcore TR-NWT-000078

ANSI/IPC J SF818

Shelflife: 2 years

Size #

Width

Inches

Color

Width

Metric

1

.030”

White

0.8mm

2

.060”

Yellow

1.5mm

3

.080”

Green

2.0mm

4

.110”

Blue

2.8mm

5

.145”

Brown

3.7mm

6

.210”

Red

5.3mm

BGA

-

Purple

-

STATIC DISSIPATIVE PACKAGING

Soder-Wick

SD is packaged on Static

Dissipative bobbins in 5 and 10-foot lengths

to minimize the risk of damage associated

with static electricity. The static dissipative

bobbins qualify as electrostatic discharge

protective per MIL-STD-1686C and MIL-

HDBK-263B, and meet the static delay rate

provision of MIL-B-81705C.

TDS # SWick

CHEMTRONICS

Technical Data Sheet

Soder-Wick

Desoldering Braid