Carrier PREMIERLINK 33CSPREMLK User Manual

Page 34

34

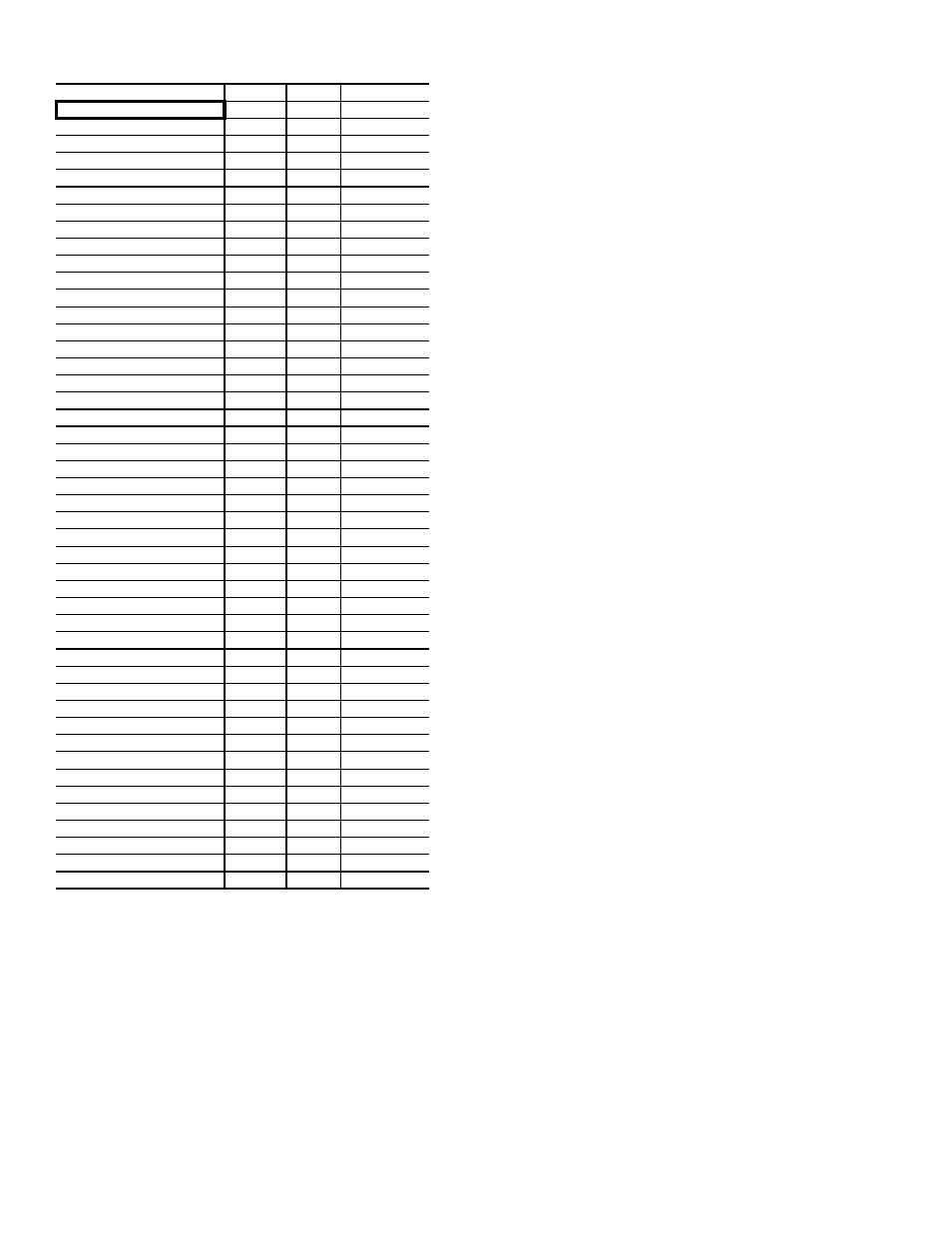

Table 14 — Service Configuration Selection

STAGED COOLING — The staging function is used for DX

cooling (1 or 2 stages). The staging function uses the cooling

submaster reference from the PID and compares the value to

the supply air temperature to calculate the required number of

output stages to energize.

Time Guard delays are provided to allow for up to 2 stages

of compression. Also, a DX Lockout will prevent operation

of the DX cooling if the outdoor air temperature is below this

value.

The cooling algorithm controls the valve or stages of DX

cooling to prevent the space temperature from exceeding the

current cooling set point (which includes any calculated offset

value from a T56 sensor slide bar during occupied periods).

Also, the cooling is controlled so that the supply air tempera-

ture does not fall below 50 F when cooling is active.

If number of stages is set to 1, then the SAT CMP2 LOCK-

OUT TEMP will be used as the low supply air set point.

Number of Stages:

Range:

1 to 3

Default Value:

2

The Time Guards must be set to Enable for output to a

compressor, and set to Disable for output to a valve or

compressor unloader.

Stage 1

Time Guard:

Range:

Disable/Enable

Default Value:

Enable

Stage 2

Time Guard:

Range:

Disable/Enable

Default Value:

Enable

Stage 3

Time Guard:

Range:

Disable/Enable

Default Value:

Disable

HEATING PID — The PremierLink™ controller determines

if a heating demand exists in the space. The controller reads the

space temperature sensor and compares the temperature to the

current low set point (including any calculated offset value

from a T56 or T57 sensor) during occupied periods. If it is

below the set point, and heating is configured and available, it

then calculates the required supply air temperature to satisfy

the given conditions. The calculated value (heating submaster

reference) is compared to the actual supply-air temperature and

the output is then adjusted to satisfy conditions by using a

Proportional/Integral/Derivative (PID) loop.

The Heating PID includes the following set points: Propor-

tional Gain, Integral Gain, Derivative Gain, and Starting Value.

Proportional Gain:

Range:

–100.0 to 100.0

Default Value:

6.0

Integral Gain:

Range:

–5.0 to 5.0

Default Value:

3.0

Derivative Gain:

Range:

–20.0 to 20.0

Default Value:

5.0

Starting Value:

Units:

Degrees F

Range:

40.0 to 120.0

Default Value:

75.0

STAGED HEATING — The Staged Heating function is used

for two-position valves or for electric heat (1 or 2 stages). The

staging function uses the heating submaster reference value

from the PID and compares it to the supply air temperature to

calculate the required number of output stages to energize.

Number of Stages:

Range:

1 to 3

Default Value:

2

Stage 1

Time Guard:

Range:

Disable/Enable

Default Value:

Enable

Stage 2

Time Guard:

Range:

Disable/Enable

Default Value:

Enable

Stage 3

Time Guard:

Range:

Disable/Enable

Default Value:

Enable

IAQ PID — The proportional gain affects the response of PID

calculations for staged control. The gain is also used for two-

position control to establish the hysteresis between on and off.

A larger gain speeds response time or reduces the hysteresis,

while a smaller gain requires a larger error to generate the same

response to changes in Indoor Air Quality. Enter the desired

proportional gain for the Indoor Air Quality control algorithm.

DESCRIPTION

VALUE

UNITS

NAME

Cooling PID

Proportional Gain

6.0

KP

Integral Gain

3.0

KI

Derivative Gain

5.0

KD

Starting Value

70.0

dF

STARTVAL

Staged Cooling

Total Number of Stages

2

STAGES

Stage 1 Time Guard

Enable

TG1

Stage 2 Time Guard

Enable

TG2

Stage 3 Time Guard

Disable

TG3

Heating PID

Proportional Gain

6.0

KP

Integral Gain

3.0

KI

Derivative Gain

5.0

KD

Starting Value

75.0

dF

STARTVAL

Staged Heating

Total Number of Stages

2

STAGES

Stage 1 Time Guard

Enable

TG1

Stage 2 Time Guard

Enable

TG2

Stage 3 Time Guard

Enable

TG3

IAQ PID

Proportional Gain

0.1

KP

Integral Gain

0.0

KI

Derivative Gain

0.0

KD

Starting Value

0.0

%

STARTVAL

Economizer PID

Proportional Gain

-4.0

KP

Integral Gain

-2.0

KI

Derivative Gain

-3.0

KD

Starting Value

70.0

dF

STARTVAL

Submaster Gain Limit

-5.5

ESG

Submaster Center Value

60

%

CTRVAL

Damper Movement Band

0

%

ECONBAND

OAT Temp Band

25

^F

TEMPBAND

Minimum Damper Position

20

%

MDP

Low Temp MDP Override

100

%

LOWMDP

DX Cooling Lockout

On

DXCTLO

DX Cooling Lockout Temp

45.0

dF

DXLOCK

SAT CMP1 Lockout Temp

55.0

dF

SATL01

SAT CMP2 Lockout Temp

50.0

dF

SATL02

Time Guard Override

Off

TGO

Continuous Power Exhaust

Disable

MODPE

Supply Fan Status Enable

Disable

SFSENABL

Max Offset Adjustment

2.0

^F

LIMT

Space Temp Trim

0.0

^F

RATTRIM

Supply Air Temp Trim

0.0

^F

SATTRIM