Updx series, Thermal well testing, Gas control testing – Bradford White UPDX2-75T6FRN User Manual

Page 25

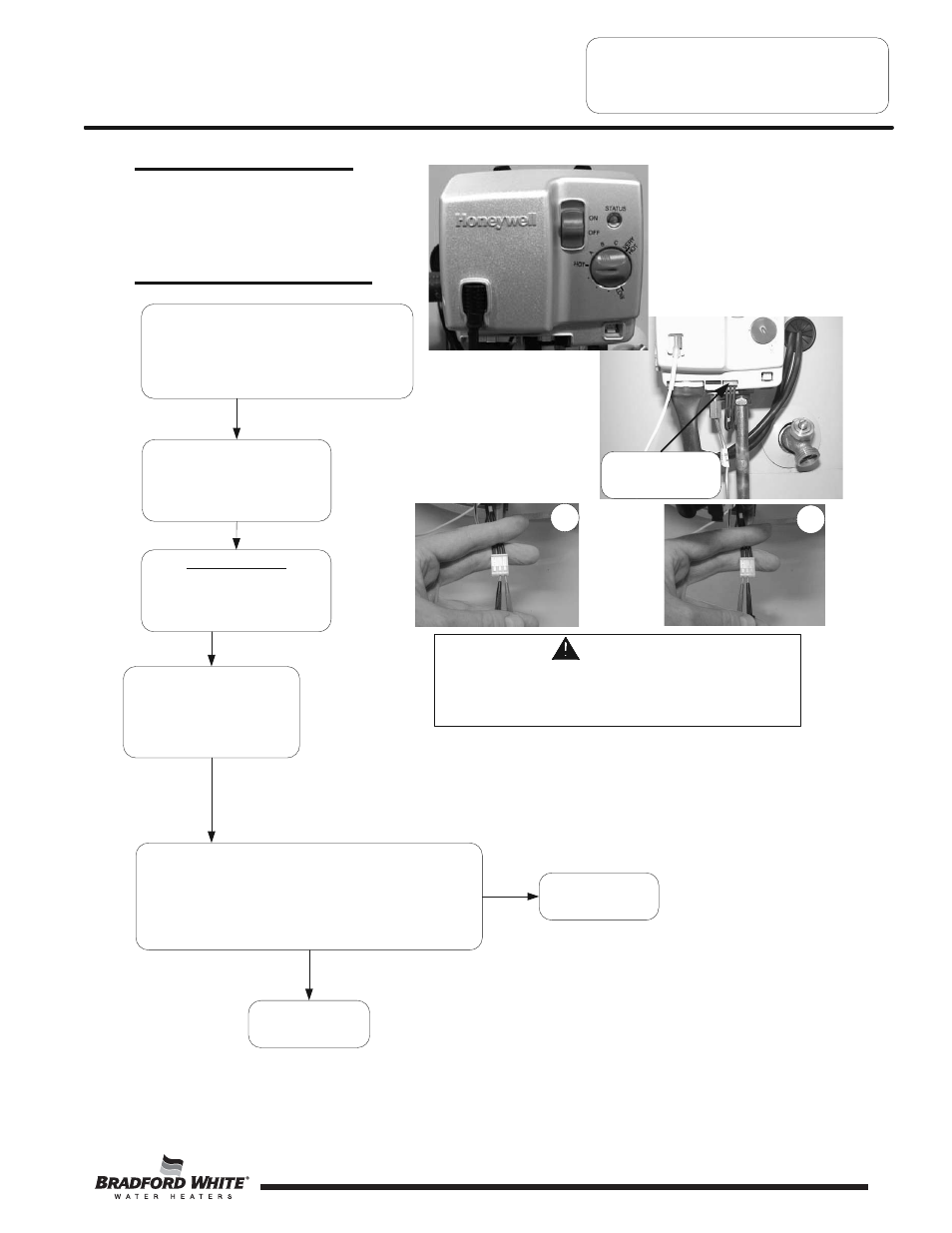

UPDX SERVICE PROCEDURE VI

Gas Control/Thermal Well Testing and

Replacement

UPDX Series

Thermal Well Testing

Thermal well testing

Position gas control power switch to

the “OFF” position and disconnect

thermal well harness from gas

control.

N

Y

Using a multi-meter set to the ohms setting, insert one meter probe (see caution)

into center wire position of thermal well connector, insert the second probe (see

caution) into either of the outside wire positions (see photo 20).

Alternate the probe on the outside position to the opposite outside wire position

(see photo 21).

Replace thermal well

(see page 27).

Using a multi-meter set to the

Ohms setting, determine the

resistance of thermal well sensor

(see caution photos 25 & 26).

Disconnect Thermal

Well Wire Harness

25

26

Replace gas control

(see page 27 or 29).

Page 25

Gas Control Testing

This section is for models with serial

Numbers starting with “K” or earlier.

See page 34 for gas control input &

output testing.

Once the thermal well resistance values are known, the water

temperature must also be known to determine if the resistance

values are correct. See page 26 to obtain water temperature.

Are thermal well resistance values correct?

CAUTION

DO NOT use standard multimeter probes for this test. Doing

so will damage connector. Use special pin type electronic

probes or small diameter wire pins inserted into connector.

If Control has gone into TCO lockout due to excessive

tank temperature (four flash, 3 second pause) reset

control by rotating knob of temperature control to the

minimum setting for at least 6 seconds before returning

to desired temperature setting.

Observe heater operation. If control

continues to lockout due to excessive

tank temperature, proceed to thermal

well testing to determine cause.

Gas Control shown in the

“OFF” Position

25